3D printing method and device of large-inclination part and electronic control multifunctional powder distribution device

A tilt angle, 3D printing technology, applied in the field of metal parts 3D printing methods and devices, can solve the problems of sticking powder, complex process, nodules, etc., and achieve the effect of eliminating molten pool flow and increasing the limit tilt angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The forming process is as follows:

[0039] (1) Part area division:

[0040] First, the part is divided into part internal area 13, part front boundary 14, part front right boundary 15, part rear boundary 16, and part left boundary 17.

[0041] (2) The corresponding nozzles are determined when forming different areas:

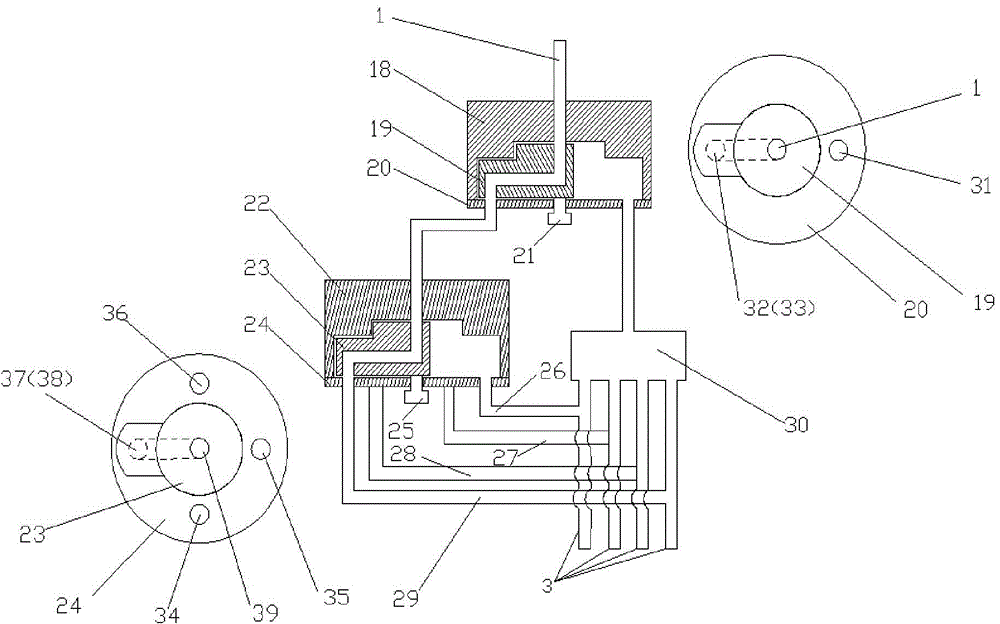

[0042] When forming the inner area 13 of the part, the powder in the powder feeding tube 1 is divided into 4 parts by the electronic control multifunctional powder distributor 2, and the distribution is sprayed by 4 nozzles (5, 6, 7, 8) at the same time. The powder feeding volume in each nozzle is 1 / 4 of the powder feeding volume of the main powder feeding pipe;

[0043] When forming the left boundary 17 of the part, all the powder in the powder feeding pipe 1 is conveyed to the left powder feeding pipe 7 through the electronically controlled multifunctional powder divider 2, and the powder is conveyed from the left powder feeding pipe 7 to the molten pool 10. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com