A method for secondary cleaning and drying of dried wolfberry fruit

A technology for secondary cleaning of dried wolfberry fruit, applied in applications, food processing, food science, etc., can solve the problems of difficult removal of wolfberry fruit, time-consuming and laborious operation, high cost, etc., to achieve product cleanliness, sanitation and safety, hygienic quality, and production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 Automatic cleaning production line of the present invention

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

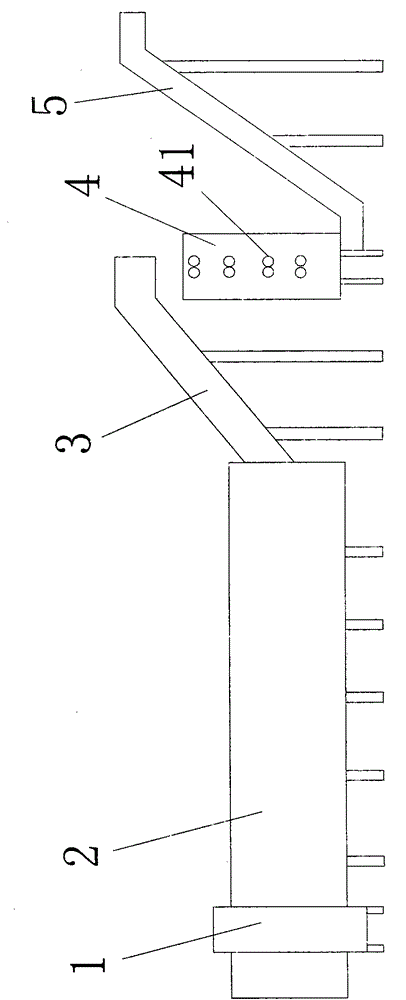

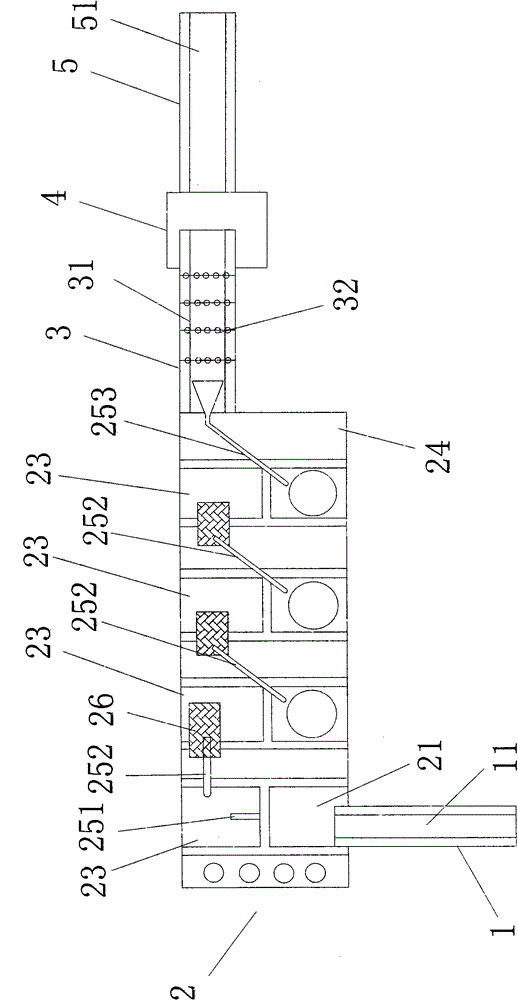

[0039] Such as figure 1 and figure 2 As shown, the present invention discloses a secondary cleaning production line of wolfberry dried fruit, which comprises a vibration feeder 1, a cleaning machine 2, a spray feeder 3, a water remover 4 and a discharger 5, and the vibration feeder The surface of the machine 1 is covered with a stainless steel filter belt I11, the aperture of the stainless steel filter belt I11 is below 4mm, the stainless steel filter belt I11 is driven by a motor, and the outlet of the vibrating feeder 1 is located above the cleaning machine 2; the cleaning machine 2 includes cleaning The container 21, the floating cleaner 23 and the water recovery tank 24, the cleaning container 21 and the floating cleaner 23 are connected by a feeding pipeline I251, the fe...

Embodiment 2

[0043] Embodiment 2 Secondary cleaning and drying method of dried wolfberry fruit of the present invention

[0044] (1) Secondary cleaning of dried wolfberry fruit:

[0045] placing the dried wolfberry fruit in an automatic cleaning production line for cleaning to obtain wolfberry with moisture removed from the outer surface;

[0046] (2) The dry fruit of wolfberry is dried as follows:

[0047] a. Initial drying: Take the dried wolfberry fruit after washing, remove most of the surface moisture, and set aside; first, raise the temperature of the initial drying section of the belt dryer to 75-80°C, and then move the wolfberry to the initial drying section through the conveyor belt. The drying time is 20 to 35 minutes, and at the same time, the moisture is removed through the dehumidification fan;

[0048] b. Mid-drying: After the initial drying is completed, the wolfberry is transported to the middle-drying section of the belt dryer. The temperature in the middle-drying sectio...

Embodiment 3

[0052] Embodiment 3 Secondary cleaning and drying method of dried wolfberry fruit of the present invention

[0053] (1) Secondary cleaning of dried wolfberry fruit:

[0054] placing the dried wolfberry fruit in an automatic cleaning production line for cleaning to obtain wolfberry with moisture removed from the outer surface;

[0055] (2) The dry fruit of wolfberry is dried as follows:

[0056] a. Initial drying: Take the dried wolfberry fruit after washing, remove most of the surface moisture, and set aside; first, raise the temperature of the initial drying section of the belt dryer to 70-75°C, and then move the wolfberry to the initial drying section through the conveyor belt. The drying time is 35-50 minutes, and at the same time, the moisture is removed by the dehumidification fan;

[0057] b. Mid-drying: After the initial drying is completed, the wolfberry is transported to the middle-drying section of the belt dryer. The temperature in the middle-drying section is mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com