A novel peeling machine

A peeling machine, a new type of technology, applied in the peeling of vegetables or fruits, food science, applications, etc., can solve the problems of high labor costs, inconvenient cleaning of the barrel, and low efficiency, so as to save labor costs and prevent shaking. Good, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

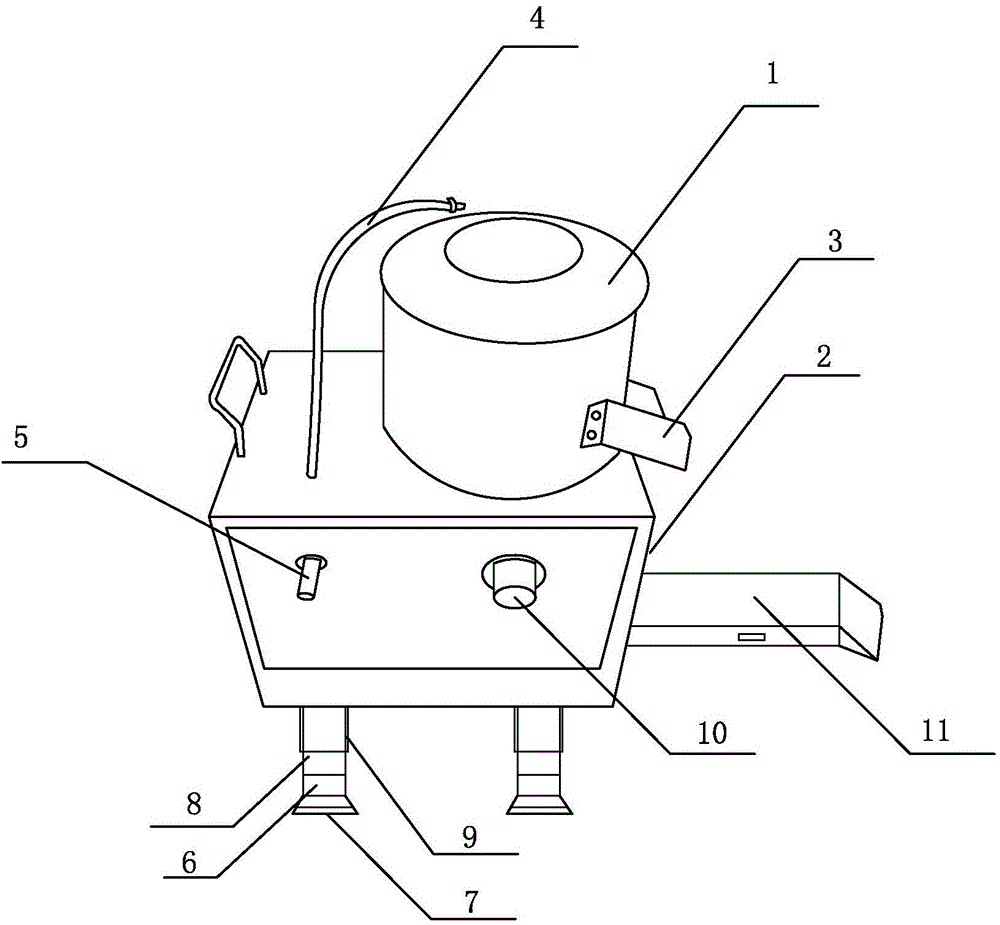

[0008] refer to figure 1 , the specific embodiment adopts the following technical solutions: it includes a peeling cylinder 1, a box body 2, a discharge port 3, a flushing water pipe 4, a water inlet pipe 5, a bottom leg 6, a gasket 7, an internal spiral column 8, an external thread Cover 9, water outlet 10 and weighing device 11, a peeling cylinder 1 is arranged above the box body 2, and a discharge port 3 is provided on the outer wall of the peeling cylinder 1, and a weighing device is provided below the discharge port 3. Device 11, one side of the peeling cylinder 1 is provided with a flushing water pipe 4, the flushing water pipe 4 communicates with the water inlet pipe 5, and the outer wall of the box body 2 is provided with a water outlet 10, and several external threaded sleeves 9 are arranged below the box body 2 , the external thread sleeve 9 is internally screwed with an internal thread column 8, a bottom leg 6 is provided below the internal thread column 8, and a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com