Straw secondary chopping and spreading machine

A straw and frame technology, which is applied in the field of crop straw secondary chopping and spreading machine, can solve the problems of not reaching the user, cutting stubble height, and the ground roller is easy to stick to soil and grass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

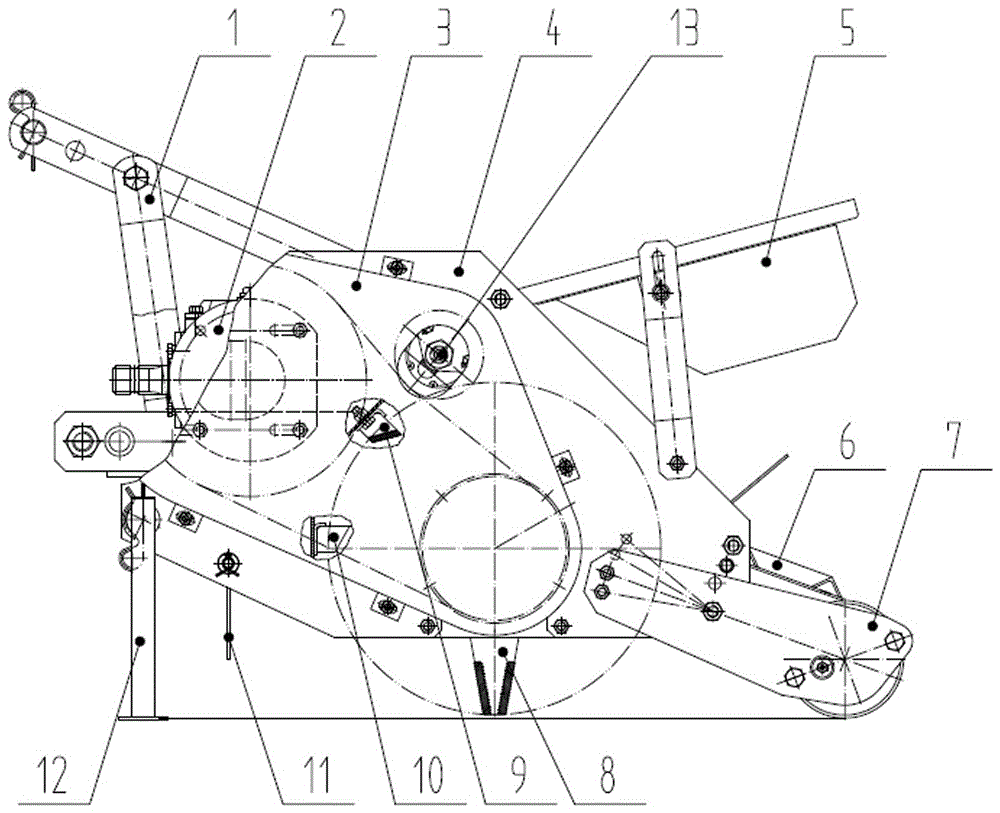

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

[0012] The straw secondary chopping and throwing machine is composed of a suspension frame 1, a frame 4, a leg 12 and various parts of the assembly. Leg 12, the upper right part of frame 4, the bottom and the front of support leg 12 are respectively provided with divider plate assembly 5, chopping knife shaft assembly 8 and retaining grass curtain 11, the front and the back middle part of frame 4 are from top to bottom. The upper fixed knife row 9 and the lower fixed knife row 10 are respectively arranged on the lower part; the transmission box assembly 2 is located inside the frame 4 on one side of the suspension frame 1, and the transmission box assembly 2 and the ground roller assembly 7 are connected by belt transmission. , a pulley guard 3 is provided on the outside of the belt, a tensioning device 13 is provided on the upper part of the belt, one side of the ground r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com