Composite cement road plate ground roller bracket

A ground-rolling bracket and composite technology, which is applied to roads, tracks, movable tracks, etc., can solve the problems of repeated investment in material costs, wear of wire ropes and sleepers, weak compression resistance, etc., to improve the speed of maintenance and replacement, and increase the strength. and stability, improve the effect of installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

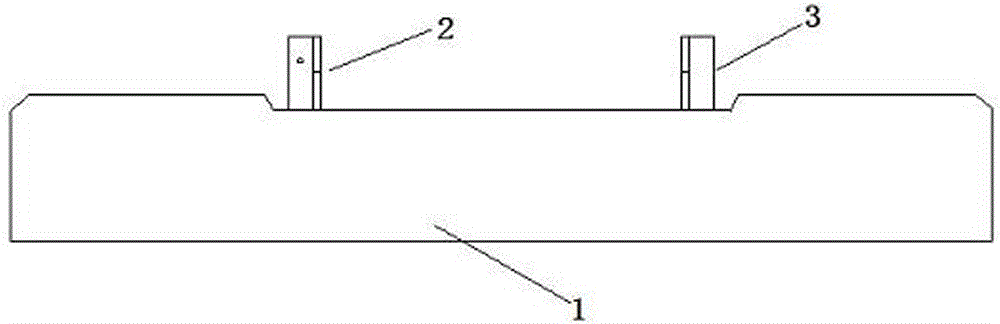

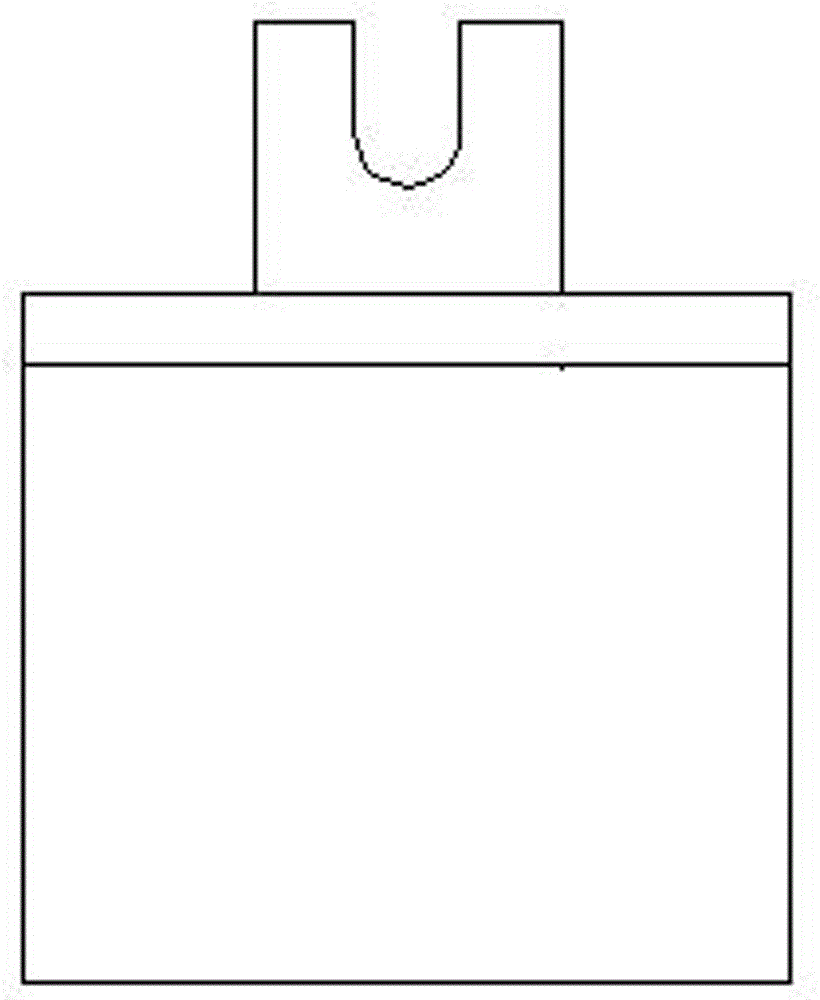

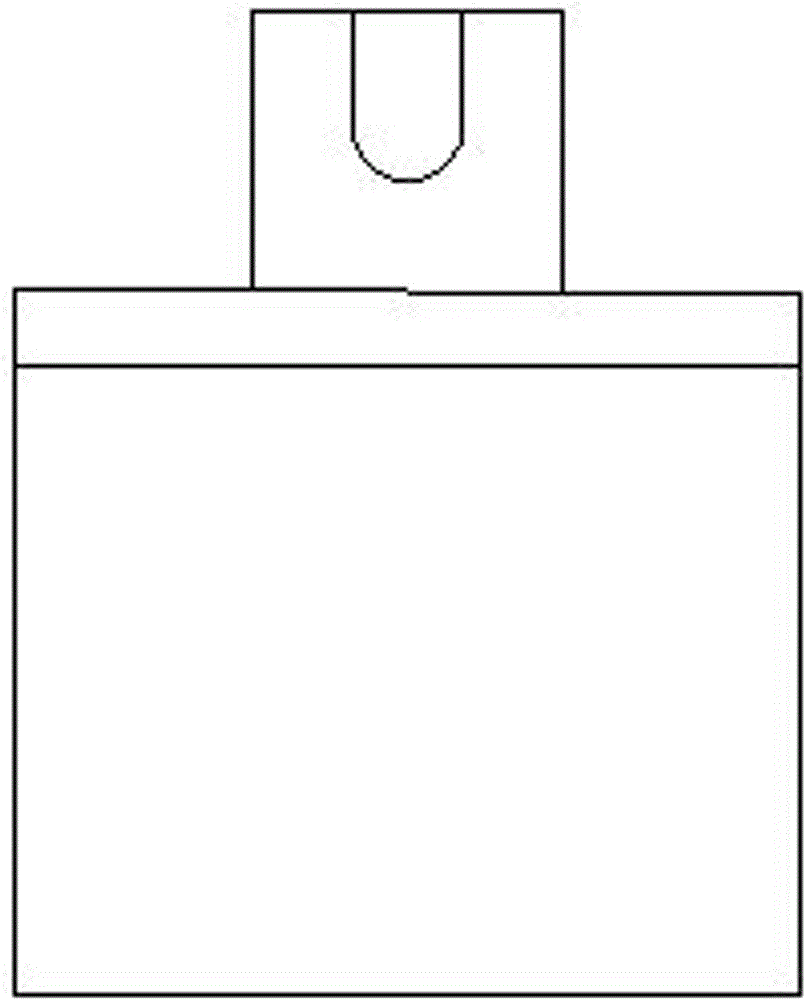

[0013] refer to Figure 1-3 , it includes cement road slab 1, ground roll bracket 2, ground roll bracket 3, ground roll bracket 2 and ground roll bracket 3 are respectively installed on cement road slab 1, and ground roll bracket 2 and ground roll bracket Frames 3 are installed on the same horizontal line, the ground roll bracket 2 is an open type, and the ground roll bracket 3 is a socket type.

[0014] The present invention is a compound design. The processed ground rolling bracket is pre-embedded while the cement track slab is manufactured, and the track slab and the ground rolling bracket are integrated into one body. The bracket effectively increases the strength and stability of the ground roll bracket, and reduces the repeated investment in system material costs; the ground roll bracket fixing frame is a slot-type design with one side hole and one side opening, which is convenient for rolling disassembly and installation , Improve the maintenance and replacement speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com