Applicable to the device and method for improving the yield of welding leaders for double-stand cold rolling mills

A welding device and double-stand technology, which is applied in cold rolling equipment and cold rolling field, can solve the problems of low yield rate and achieve the effects of reducing production cost, improving cold rolling efficiency and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

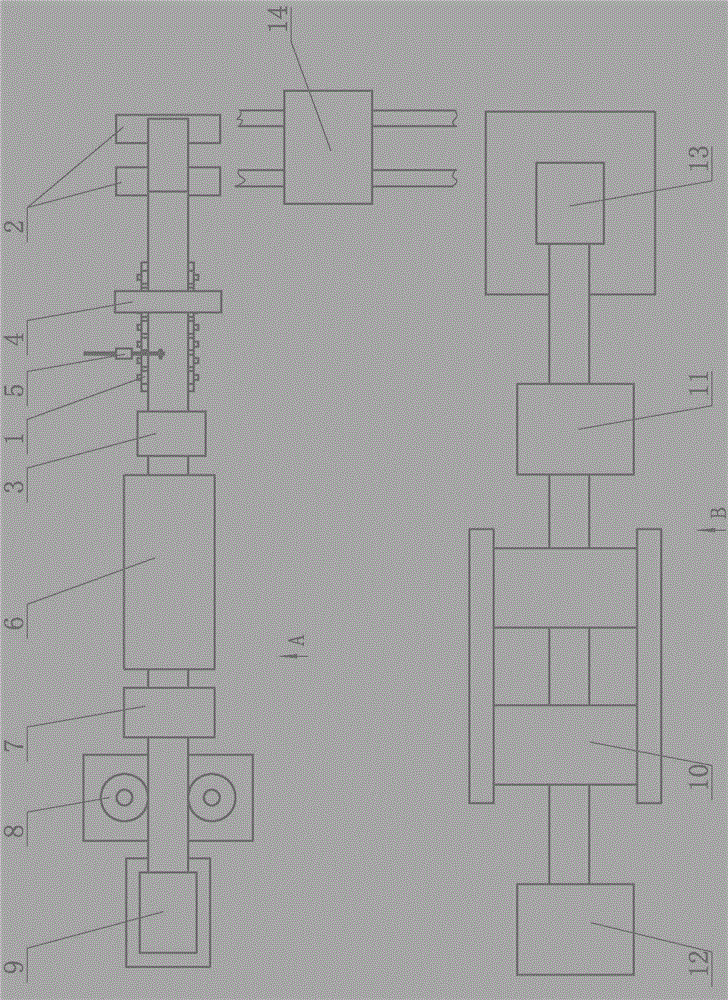

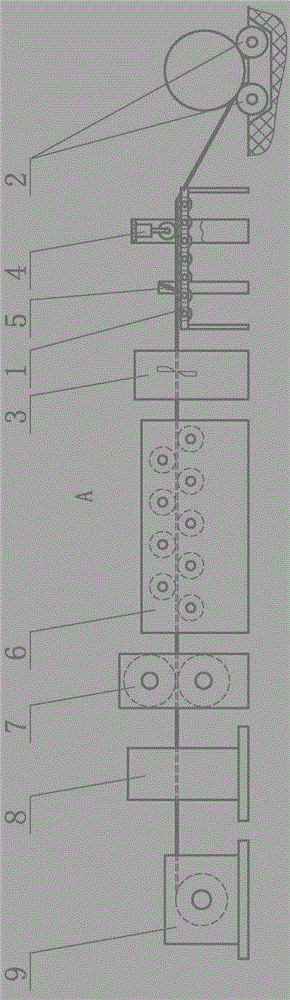

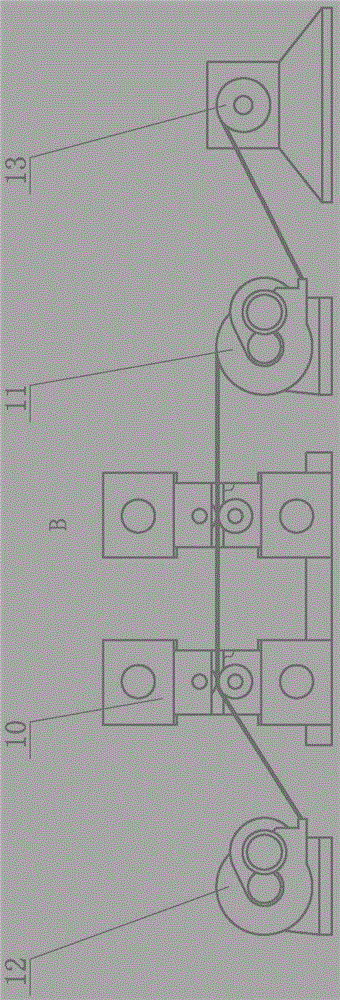

[0020] The device for improving the yield rate of the welding lead strip suitable for the double-stand cold rolling mill of the present invention includes the lead strip off-line welding device and the double-stand rolling equipment, between the lead strip off-line welding device and the double-stand rolling equipment A lifting device 14 is provided. The off-line welding device for the lead belt includes a roller table 1, two floor rollers 2 at one end of the roller table 1, a cross-cutting shear 3 at the other end of the roller table 1, and an end of the roller table 1 close to the floor roller 2 can be lifted The side of the roller table 1 is close to the cross-cutting shear 3. A welding machine 5 is installed at one end of the roller table 1. The welding head of the welding machine 5 is located above the roller table 1, and the side of the cross-cutting shear 3 away from the roller table 1 is sequentially installed with a straightening machine 6 , Pinch roll 7, centering roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com