Shot peening device and shot peening method

A technology of shot peening and spray chamber, which is applied in the field of shot peening devices, can solve problems such as poor operability and increased burden on staff, and achieve the effect of reducing time and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

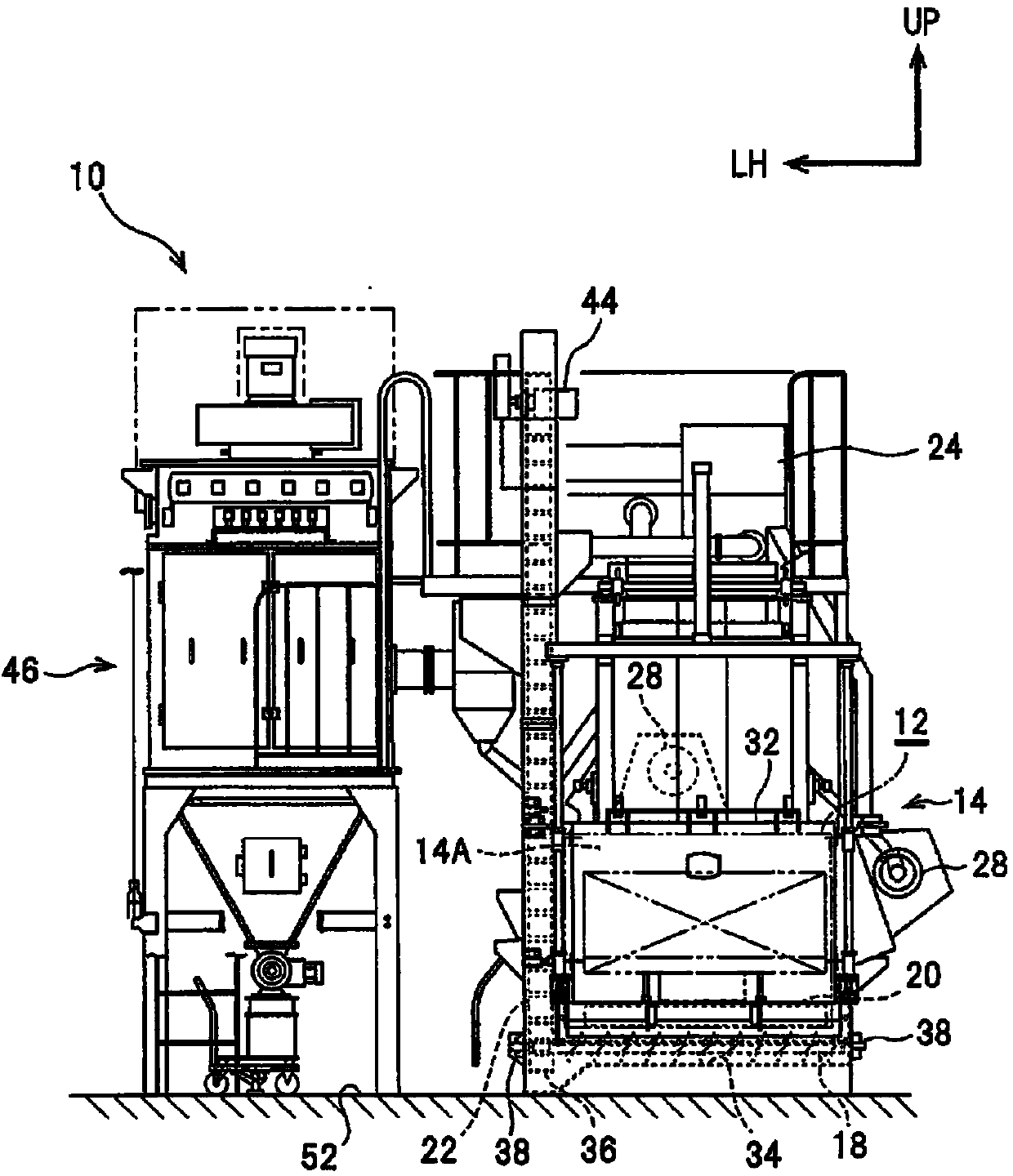

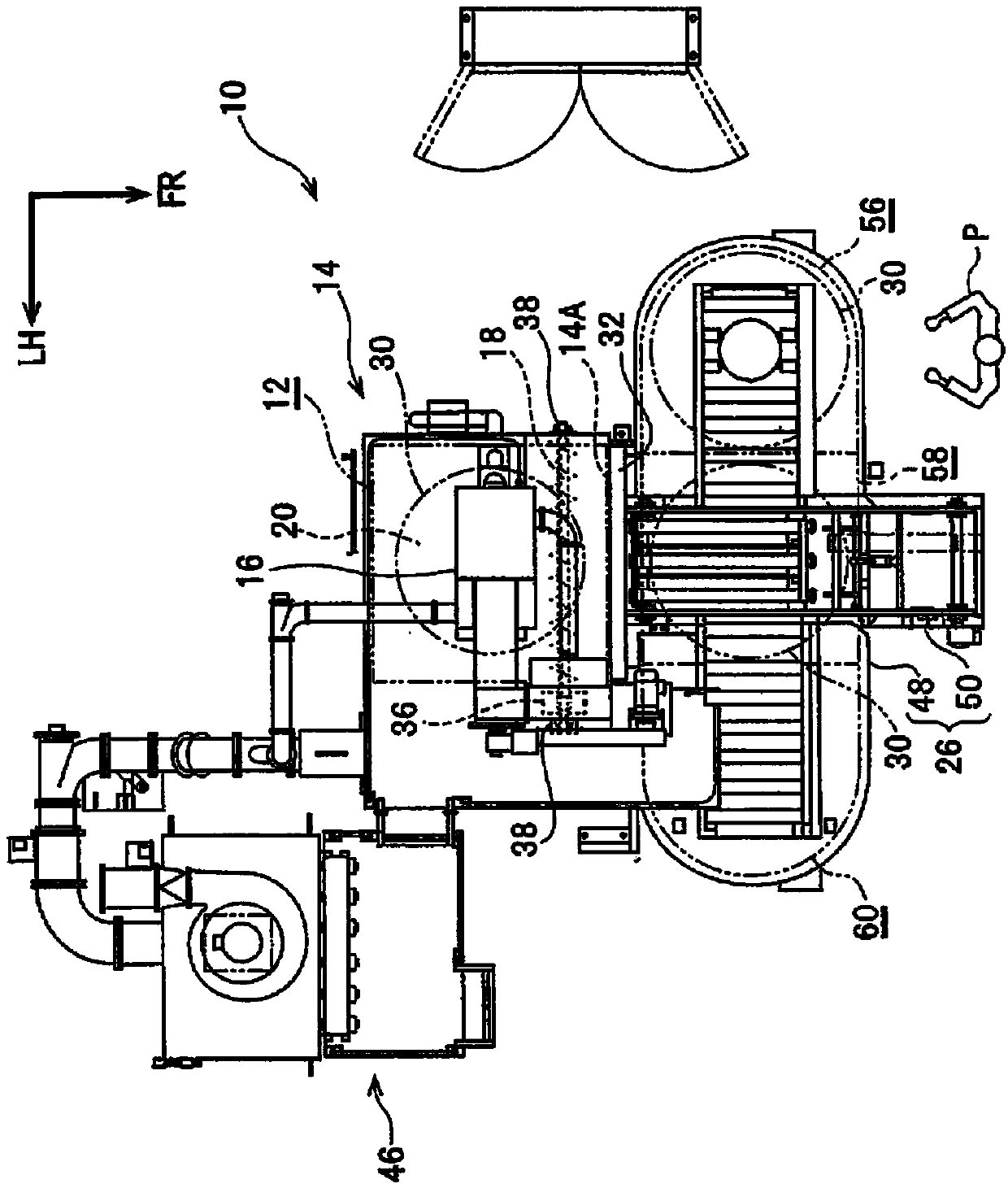

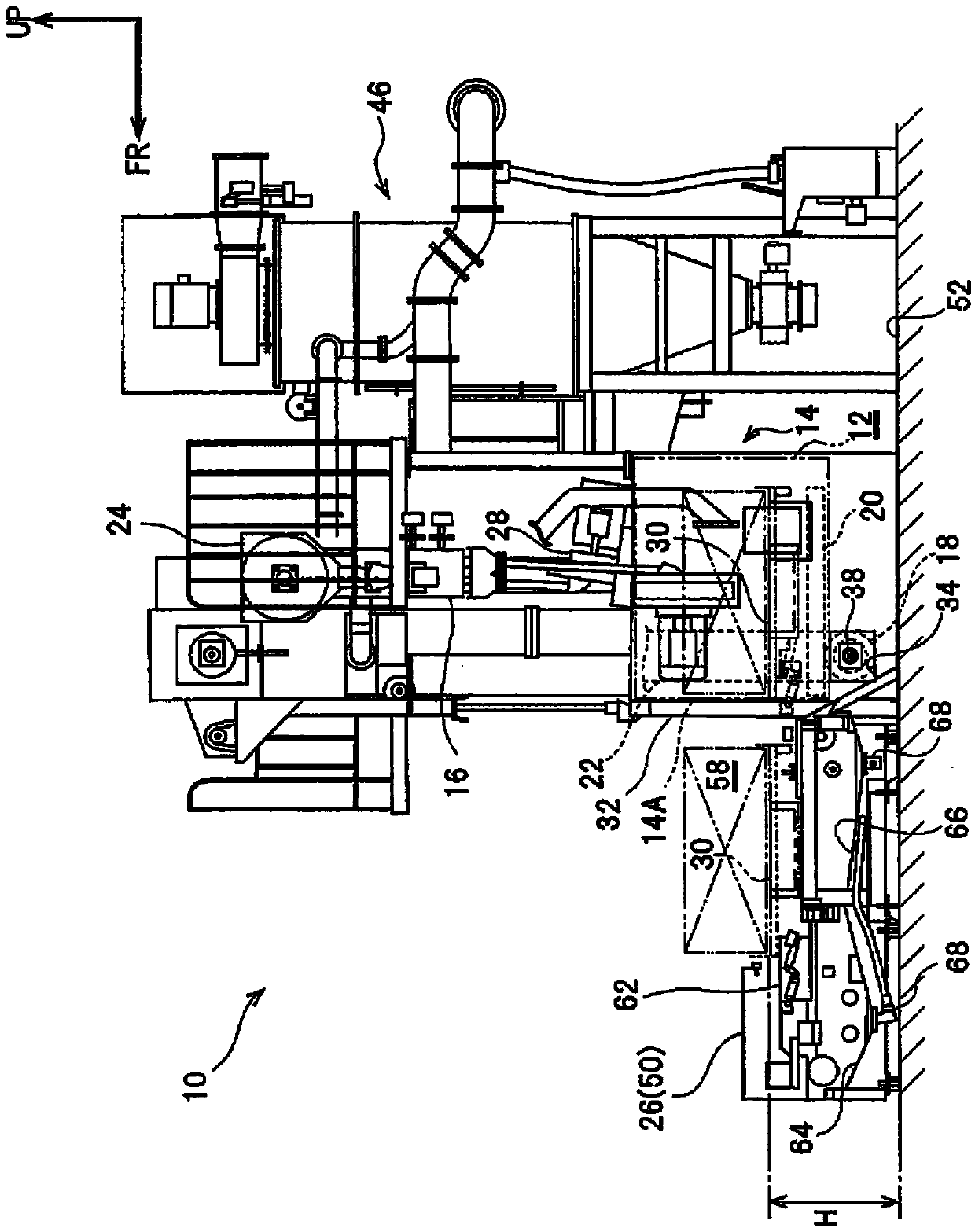

[0033] (Shot blasting device)

[0034] use Figure 1 ~ Figure 4 The shot blasting apparatus which is a shot blasting apparatus which concerns on embodiment of this invention is demonstrated. Among them, the arrow FR appropriately shown in the above drawings indicates the front side (near side) in the front-rear direction when the device is viewed from the front, the arrow UP indicates the upper side of the device, and the arrow LH indicates the left side when the device is viewed from the front. . In addition, in the following description, when the directions of front and rear, up and down, and left and right are used unless otherwise specified, they mean front and rear in the front and rear direction of the device, up and down in the up and down direction of the device, and left and right in the left and right direction of the device.

[0035] like figure 1 As shown, the shot blasting device 10 as the shot blasting processing device according to the present embodiment incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com