Gate shears

A shearing machine and gate-type technology, which is applied in the direction of shearing machine equipment, shearing devices, shearing machine accessories, etc., can solve the problem of increasing the height of the whole machine, the inability to place the front fulcrum, the front fulcrum guide rail, and the large gate-type shearing plate. Machine difficulties and other problems, to achieve the effect of ensuring the quality of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] This technology is a gate-type shearing machine with simple blade clearance adjustment, high precision, small overall structure of the front fulcrum, simple structure of the whole machine and low cost.

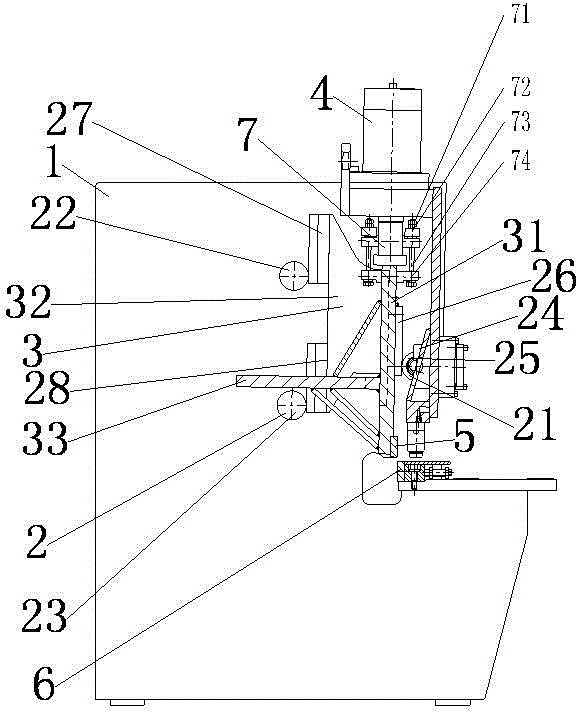

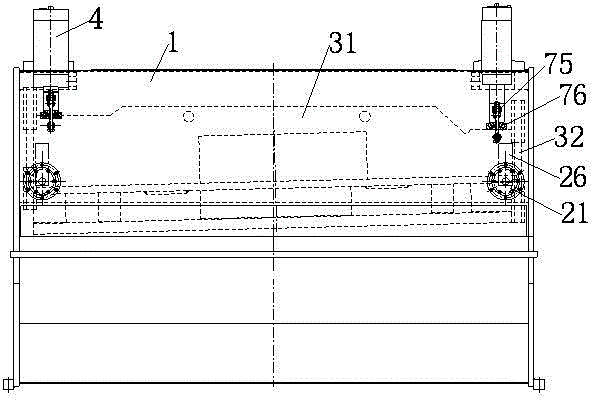

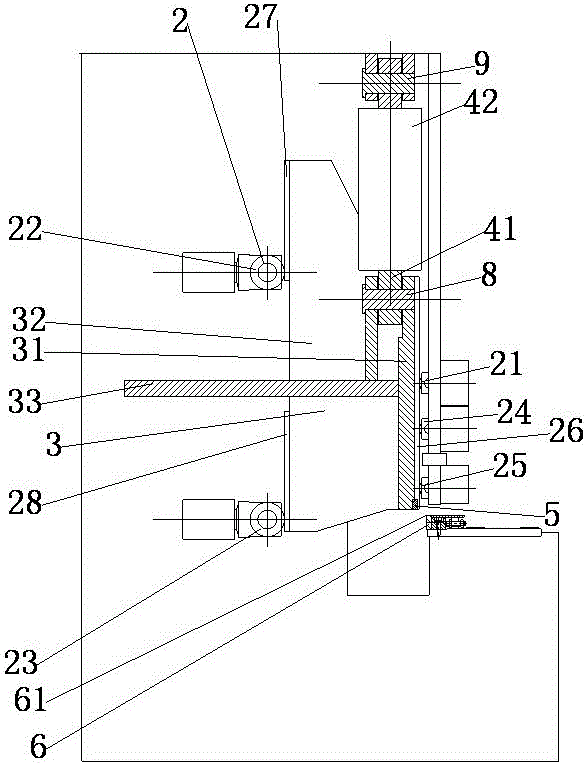

[0030] see image 3 , 4 The gate-type shearing machine of the present technology shown includes a frame 1, a knife rest 3 arranged on the frame through a three-point support structure 2 sliding up and down, and an oil cylinder 4 that drives the knife rest to move up and down.

[0031]Knife rest 3 comprises knife rest vertical plate 31, is fixed on the knife rest side plate 32 of knife rest both sides, is fixed on the knife rest horizontal plate 33 that extends horizontally along the knife rest vertical plate rear surface; The inclined shape of the low right side is high, the edge of the lower part of the knife rest vertical plate is fixed with the upper blade 5, and the lower blade 6 is fixed on the frame.

[0032] The three-point support structure 2 includes six fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com