Large-thrust circulating water pump motor ventilation cooling structure

A circulating water pump, ventilation and cooling technology, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve problems such as the decline of the heat dissipation performance of the stator core, the increase of the temperature rise in the dead zone of the air passage, and the influence of the stable operation of the motor, etc. The effect of reducing area, reducing product cost and complexity, improving cooling efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

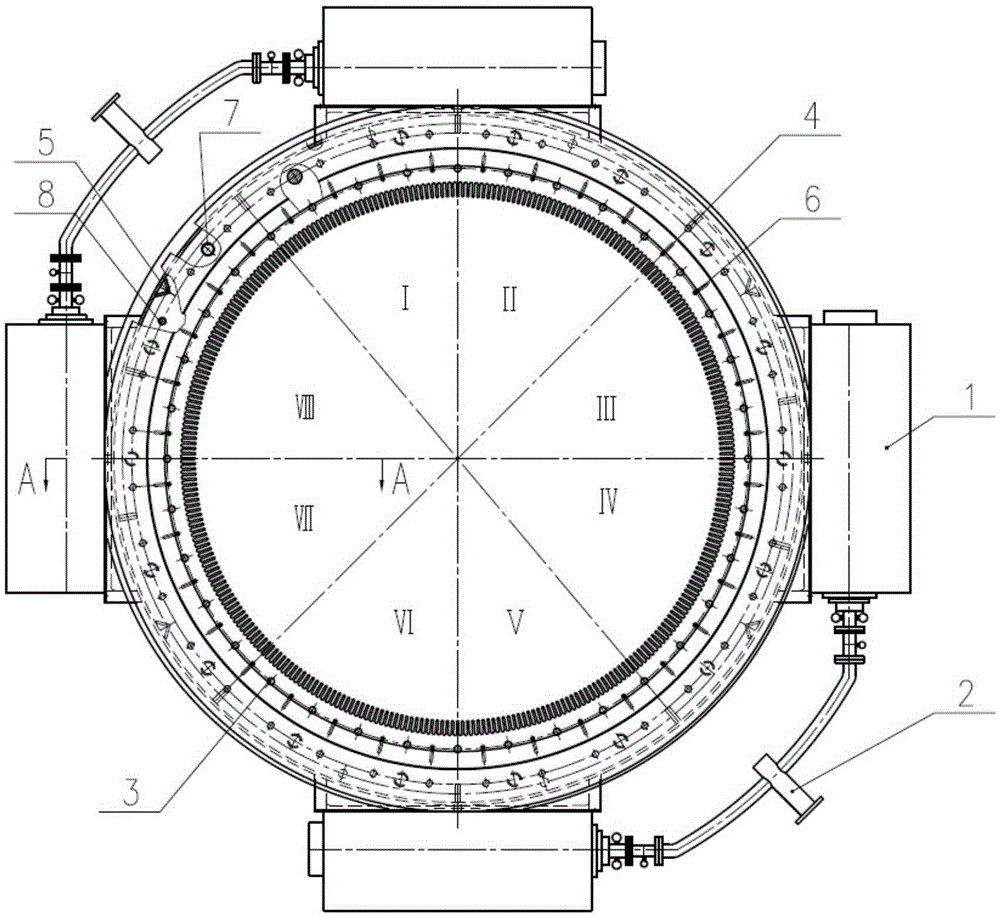

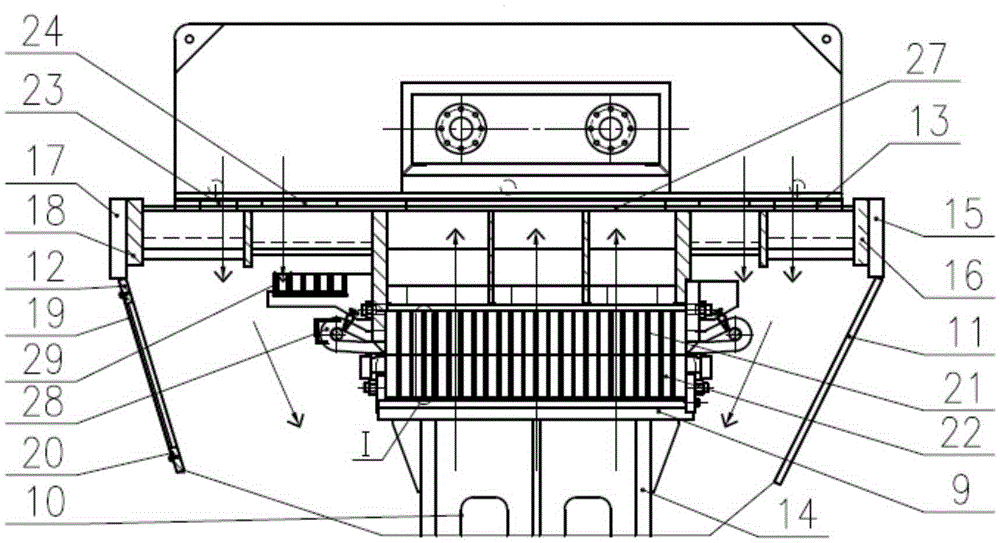

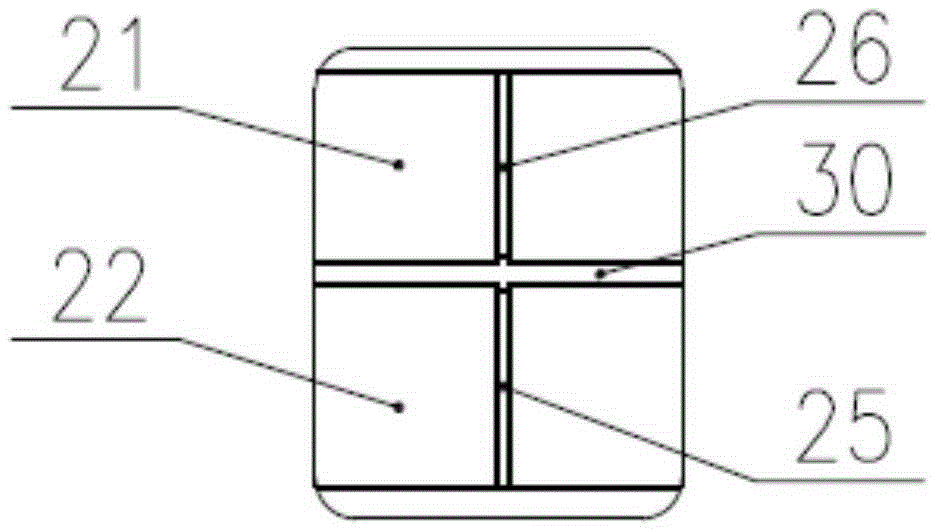

[0014] figure 1 In order to be suitable for the ventilation and cooling structure of the third-generation nuclear power high-thrust circulating water pump motor, it consists of five parts: the cooler group frame, the upper frame frame, the lower frame frame, the stator frame, and the rotor frame, such as figure 1 As shown, the air-water cooler 1 is connected with the cooler parallel tee pipe 2 to form the cooler group framework; figure 2 As shown, the lower ring plate 15 of the upper frame is tightly connected with the upper bottom plate 16 of the vertical rib, and the upper frame frame is welded by the windshield 11 of the upper frame and the upper bottom plate 16 of the vertical rib to complete the sealing structure; The frame upper ring plate 17 is tightened, the lower frame windshield 12 and the lower frame upper ring plate 17 are welded to complete sealing, and the lower frame frame is composed of a sealing plate 19 and a gasket 20 combined on the lower frame upper ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com