Dry-type transformer

A technology for dry-type transformers and high-voltage windings, which is applied to transformer/inductor components, transformer/inductor coils/windings/connections, electrical components, etc., and can solve problems such as discharge, large insulation distance, and increased cost of dry-type transformers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

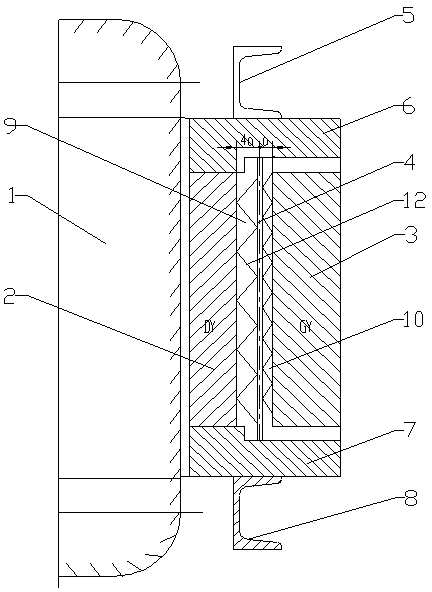

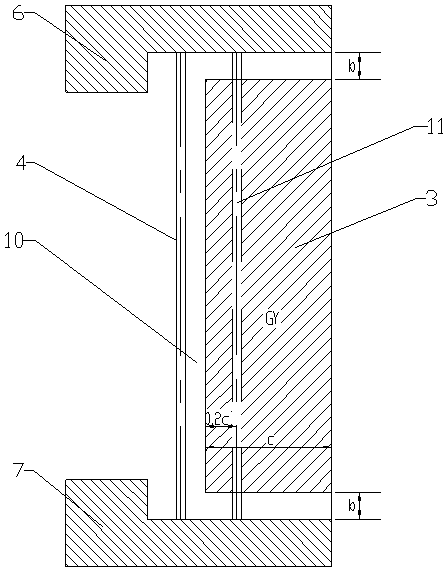

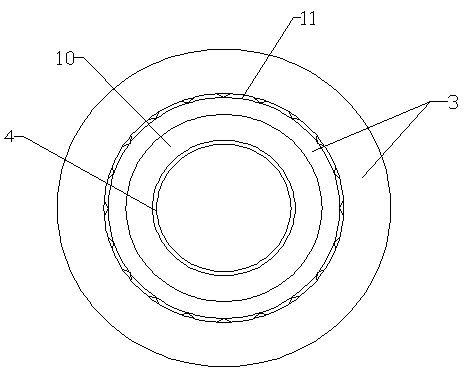

[0023] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 3 As shown, this kind of dry-type transformer includes an iron core 1, on which a low-voltage winding 2 and a high-voltage winding 3 are wound sequentially from the inside to the outside, and the high-voltage winding 3 and the low-voltage winding 2 pass through the upper clamp 5 and the upper pad 6. The lower clamp 8 and the lower pad 7 are fixed, wherein:

[0024] Add an additional high-voltage winding insulating layer 4 between the high-voltage winding 3 and the low-voltage winding 2, the upper and lower pads 6 of the high-voltage winding additional insulating layer 4, and the lower top and lower pads 7, between the low-voltage winding 2 and the high-voltage winding additional insulating layer 4 The spacer layer 10 is formed between the additional insulating layer 4 of the high-voltage winding and the high-voltage winding 3 through the support frame 12, and the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com