Lithium ion battery and notch type core rod and support pillars of lithium ion battery

A lithium-ion battery and notch technology, which is applied in the direction of secondary batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of prolonging the battery injection time, reducing the injection efficiency, and easy sliding of the battery cell, so as to improve Battery safety performance and electrochemical performance, the effect of improving liquid injection efficiency and shortening liquid injection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below through an embodiment and in combination with specific illustrations.

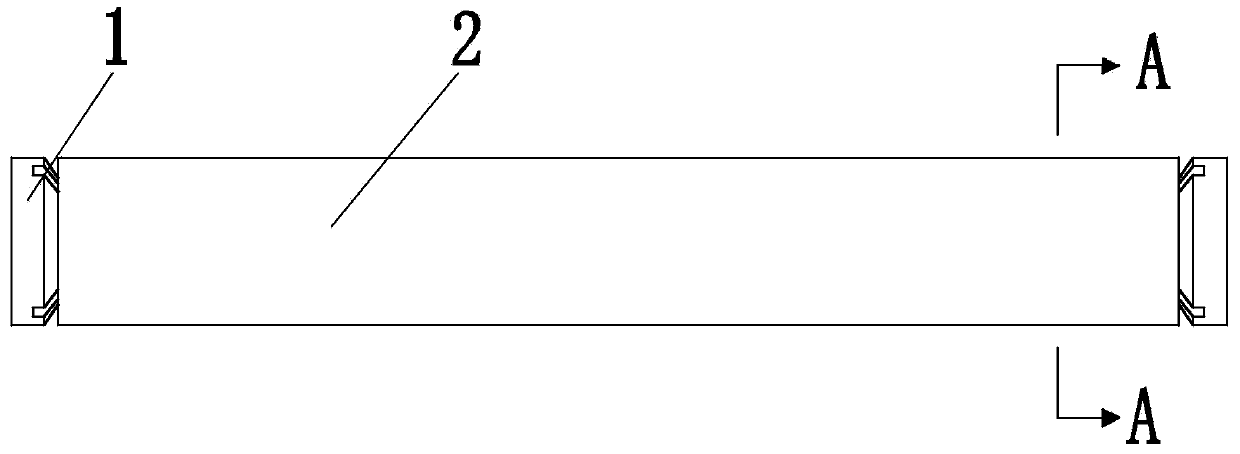

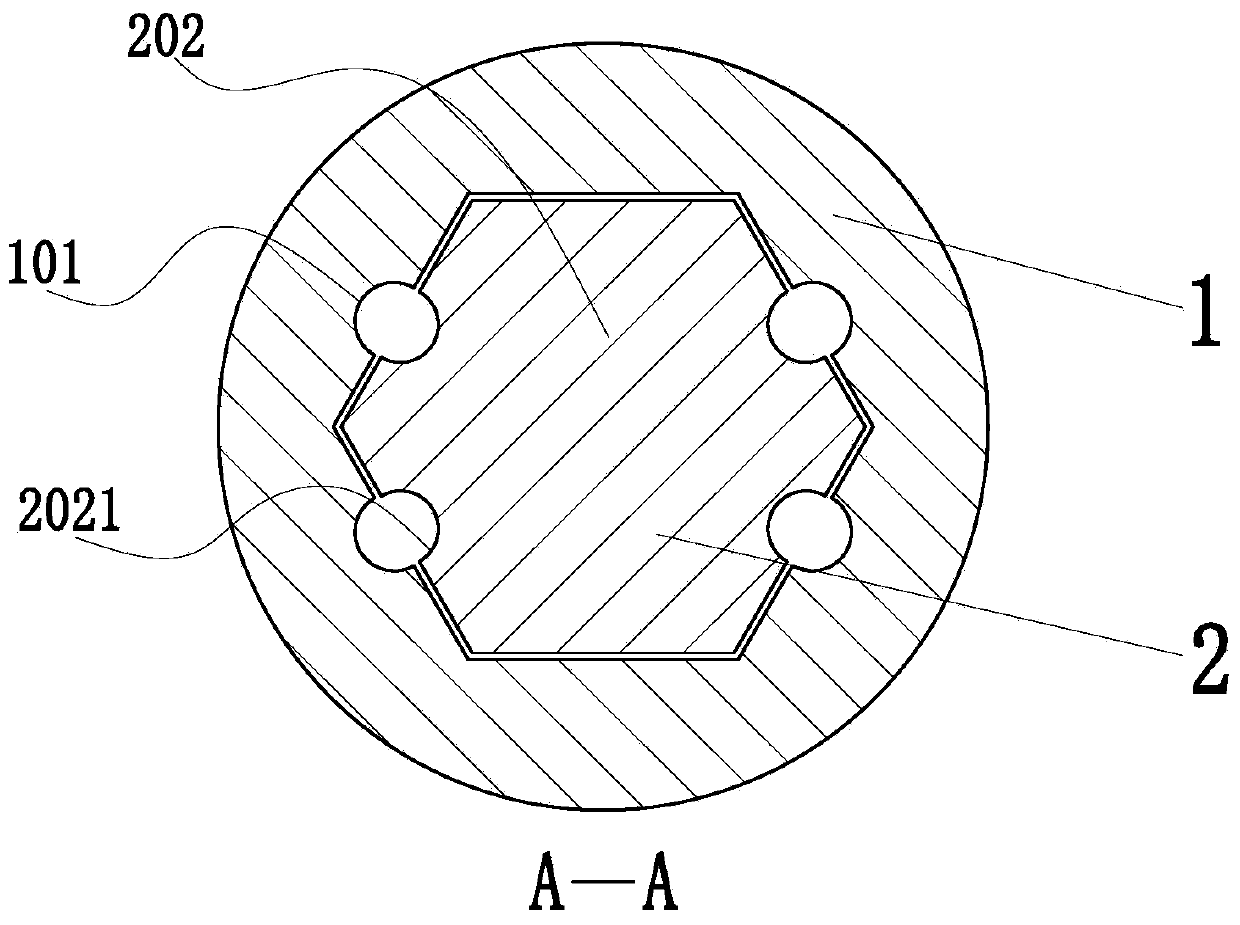

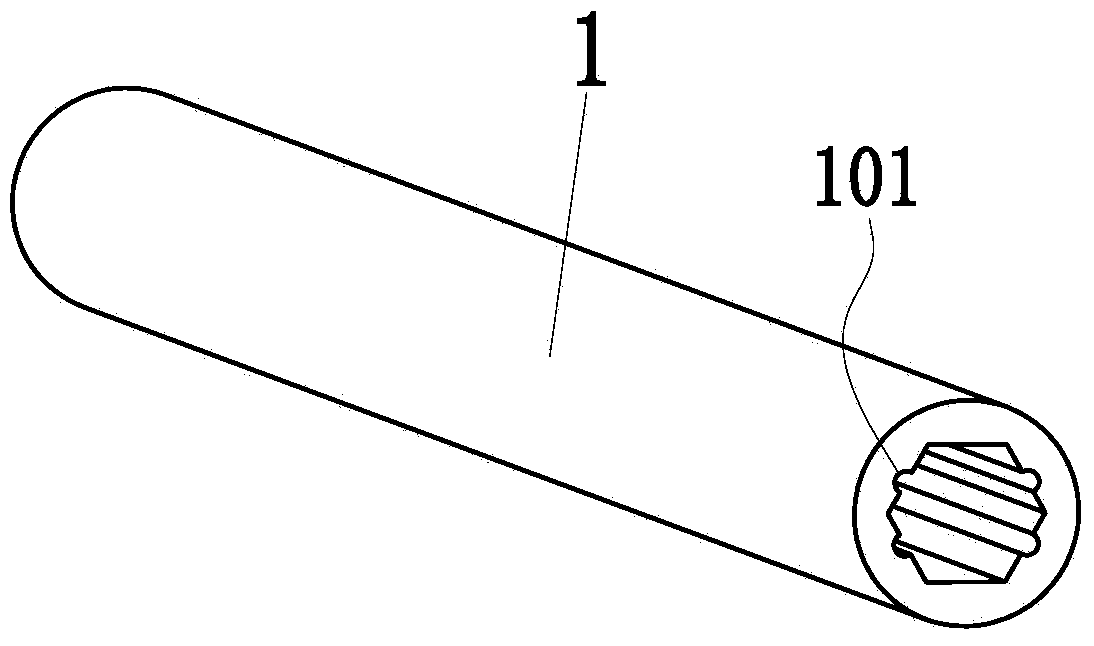

[0030] Such as figure 1 As shown, a lithium ion battery and its notched mandrel and top post according to the present invention, a lithium ion battery includes a notched mandrel 1 and two top posts 2, and the two top posts 2 are symmetrical Installed on both ends of the notched mandrel 1; the notched mandrel 1 is cylindrical, the notched mandrel 1 is provided with an inner hole, and four No. 1 grooves 101 are arranged on the wall of the inner hole, and in In this embodiment, the shape of the inner hole on the notched mandrel 1 is hexagonal, the shape of the No. 1 groove 101 is semicircular; The upper end of the column body 201 is provided with a welding platform 202, and the welding platform 202 is in the shape of a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com