Bending machine hydraulic synchronous system controlled by flow distributing and collecting valve

A diversion and flow valve, hydraulic synchronization technology, applied in the direction of fluid pressure actuators, mechanical equipment, servo motors, etc., can solve the problems of increase, hydraulic system vibration and processing errors, etc., to ensure synchronous operation and improve synchronous stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

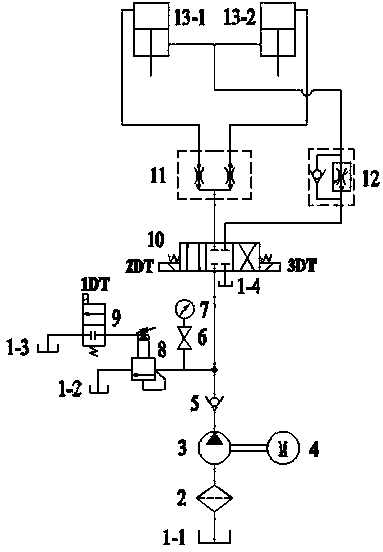

[0012] Such as figure 1 As shown, a hydraulic synchronous system of a bending machine controlled by a diverter and confluence valve of the present invention includes an oil tank 1, a filter 2, a hydraulic pump 3, a motor 4, a one-way valve 5, a pressure gauge switch 6, and a pressure gauge 7, Pilot overflow valve 8, two-position two-way electromagnetic reversing valve 9, three-position four-way electromagnetic reversing valve 10, flow diversion and flow collection valve 11, one-way speed regulating valve 12, hydraulic cylinder 13.

[0013] During the working process of the bending machine, the hydraulic pump 3 is driven by the asynchronous motor 4 to suck out the hydraulic oil in the oil tank 1, in which the hydraulic oil is filtered by the oil filter 2; after flowing through the check valve 5, the hydraulic oil is divided into two paths, One of them passes through the pilot relief valve 8 and the two-position two-way electromagnetic reversing valve 9 and then connects to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com