Filling strainer pipe

A technology of water filter pipes and chucks, which is applied in filling materials, mining equipment, earth drilling and mining, etc. It can solve the problems of high wire rope consumption, cumbersome processing procedures, and difficulty in ensuring operation safety, and achieves convenient and quick installation and improved water filtration efficiency. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

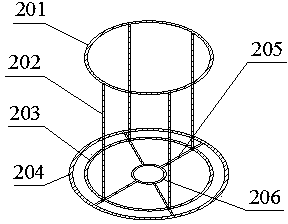

[0031] refer to figure 1 , this embodiment includes a vertically arranged water filter pipe body 3 and a steel wire rope 4, the steel wire rope 4 is located inside the water filter pipe body 3, and the upper and lower ends of the water filter pipe body 3 are sequentially provided with a steel wire rope clamp 1 and a chuck 2, The inside of the filter pipe body 3 is provided with at least one stopper 5. In practical applications, the number and positions of the stoppers 5 inside the filter pipe body 3 can be flexibly set according to the length of the filter pipe body 3, such as : The number of stoppers 5 is 2, and the two stoppers 5 are located at the middle upper part and the middle lower part of the filter pipe body 3 respectively.

[0032] refer to figure 2 , the steel wire rope clip 1 includes a first steel bead 101 and a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com