A hydraulic static pile driver suitable for narrow construction sites

A static pile driver and construction site technology, applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of inconvenient construction, inconvenient transportation, large volume, etc., and achieve convenient transfer, transfer and disassembly Convenience and effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

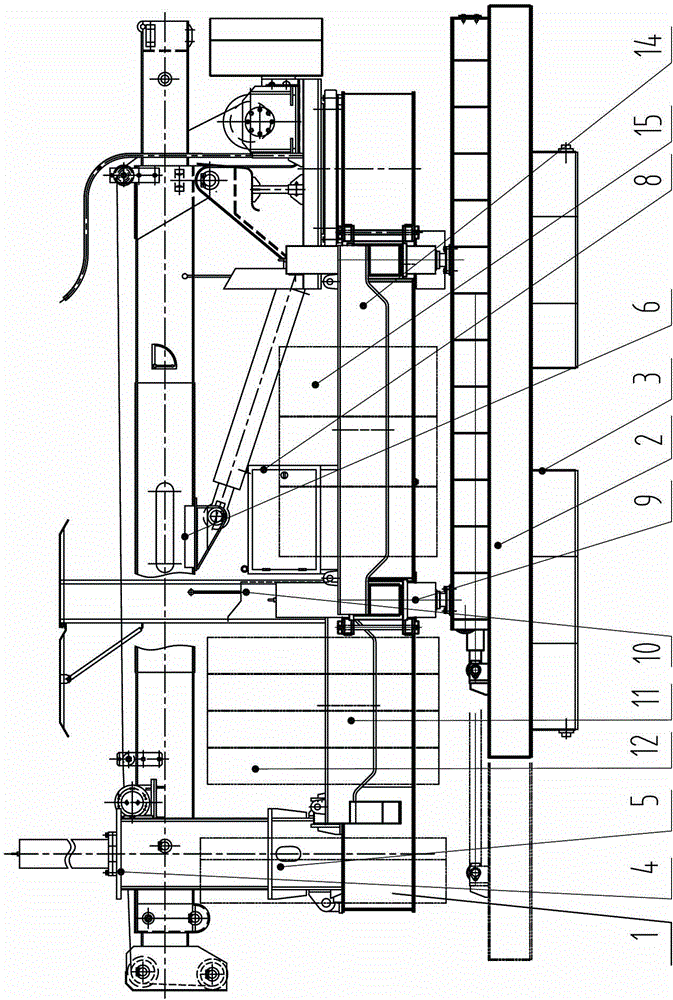

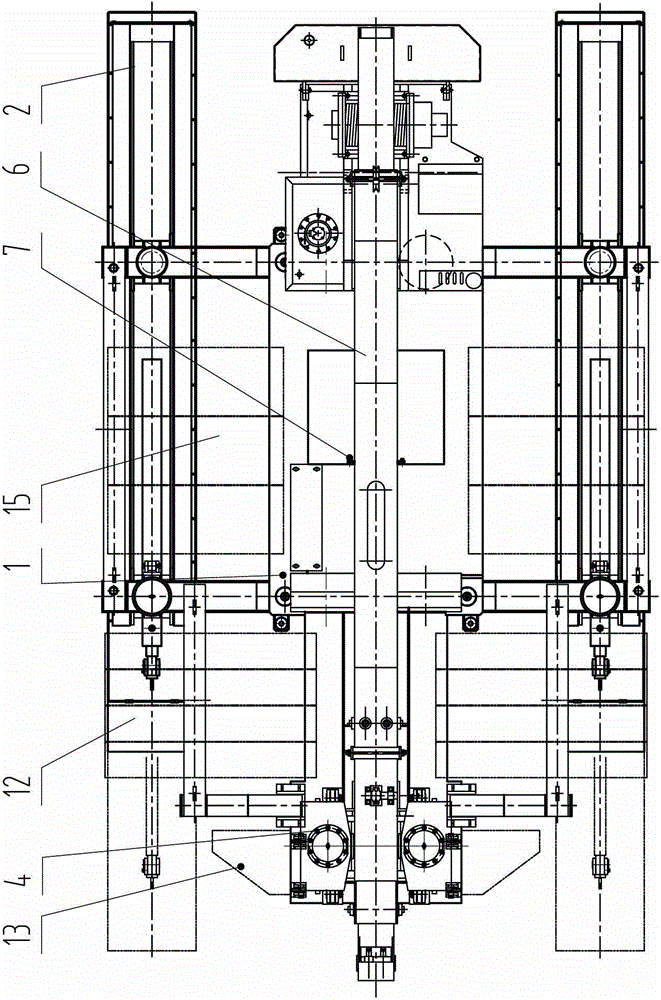

[0027] Such as figure 1 and figure 2 As shown, the present invention is a hydraulic static pile driver suitable for narrow construction sites, which includes a fuselage 1, a long boat traveling mechanism 2, a short boat traveling mechanism 3, a pile pressing mechanism 4, a pile clamping mechanism 5, a crane 6. Hydraulic system 7, electrical system 8 and console 10. The fuselage 1 is connected to the long boat running mechanism 2 through outriggers 9, and the fuselage 1 is flexibly connected to the short boat running mechanism 3 through a central axis (not shown in the figure) provided on the bottom surface, wherein:

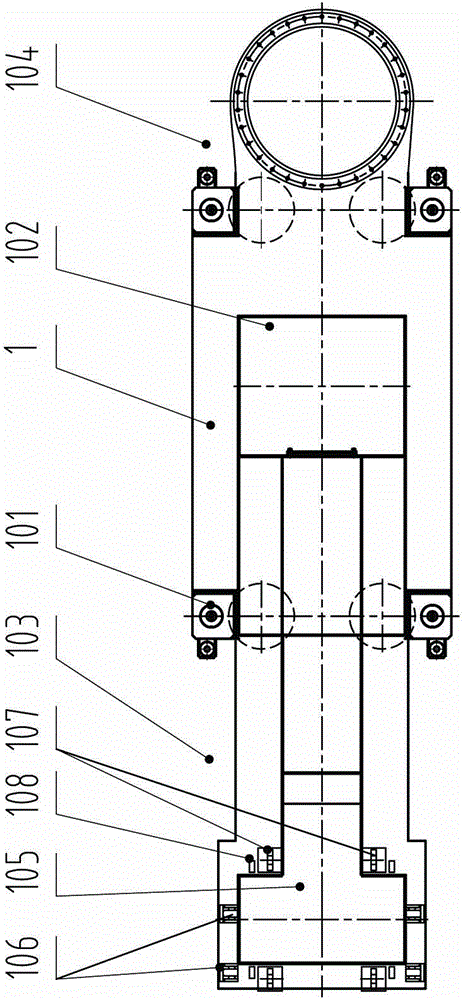

[0028] see in conjunction image 3 , under the premise that the overall width is narrowed, the fuselage 1 is designed to have a structure with narrow ends and a wide middle, and the middle pile is cancelled. The four corners in the middle of the fuselage 1 are respectively provided with leg hinge seats 101 to be hinged with the legs 9 so that the legs 9 can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com