A growth method and application of small-diameter, metallic single-walled carbon nanotubes

A technology of single-walled carbon nanotubes and a growth method, which is applied in the direct field of controllable preparation and metallic single-walled carbon nanotubes, can solve the problems of complex process and damage to the structure of carbon nanotubes, and achieves the effect of a large amount of doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

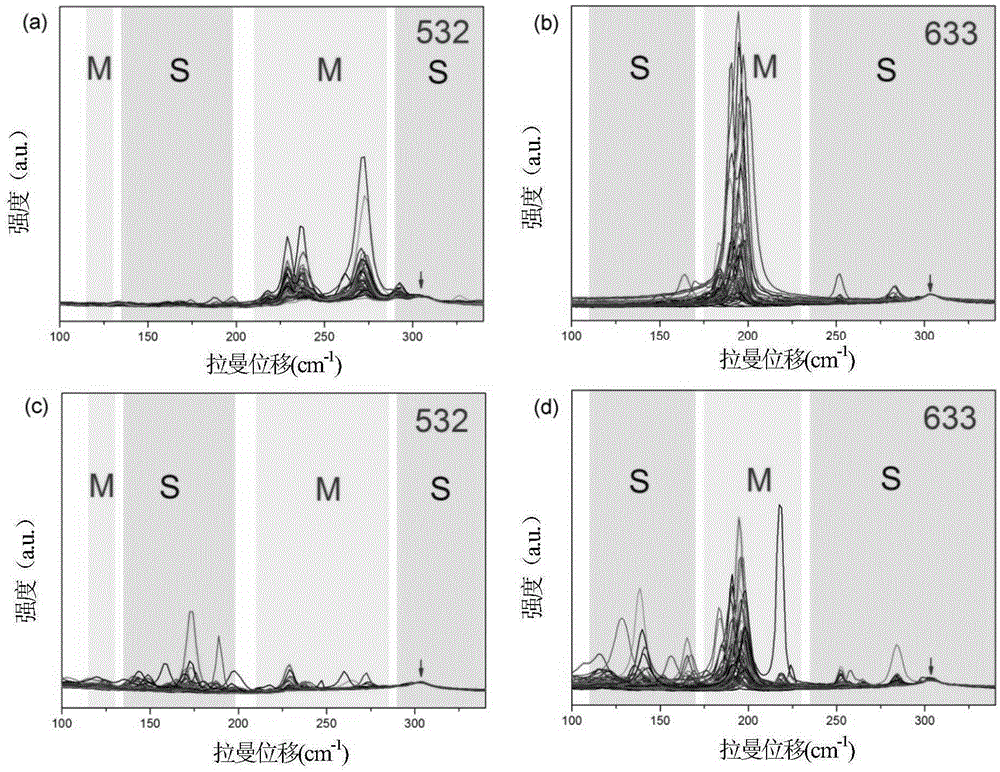

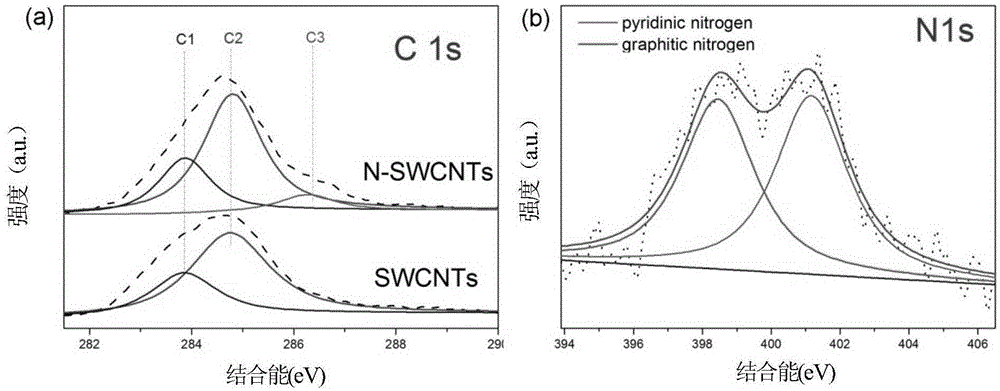

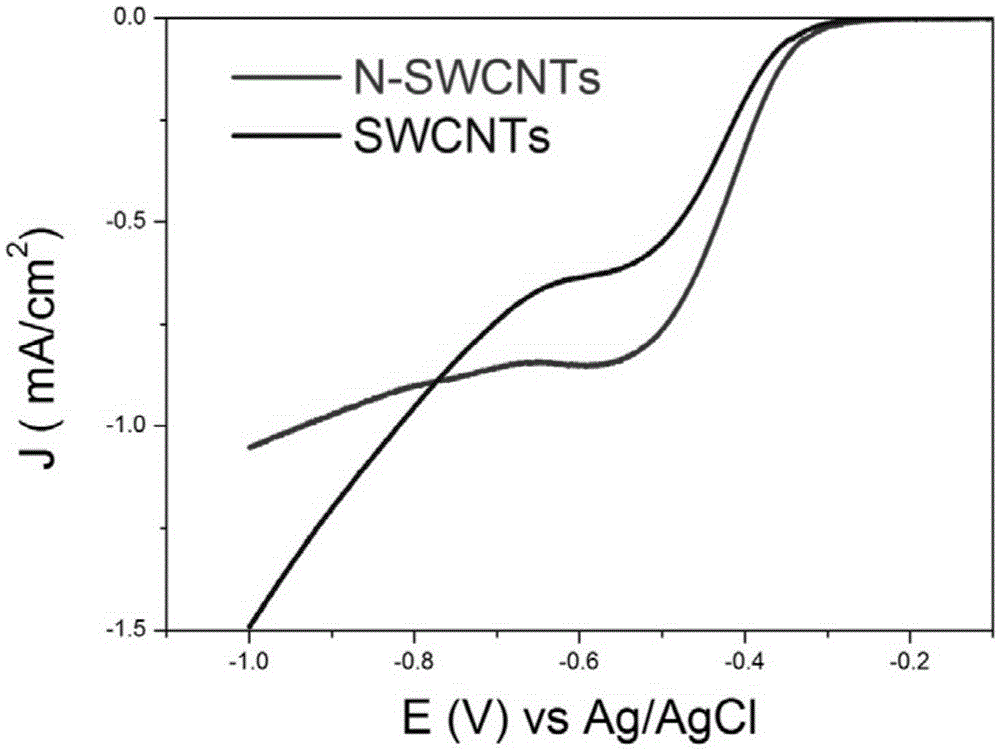

[0033] After raising the temperature of the chemical vapor deposition furnace to 900°C, place the p-type silicon wafer sputtered with a 30nm silicon oxide film in the low-temperature area of the furnace tube of the reaction furnace, seal the tube furnace, vacuumize it to about 10Pa, and then evacuate it at 50ml / min. The flow rate of hydrogen and the flow rate of 300 ml / min of argon are fed until normal pressure is restored. Then, push the silicon wafer to a constant temperature zone of 900°C for heat treatment for 10 minutes; then change the flow rate of 200 ml / min to the argon-carried precursor (ethylenediamine, kept at a constant temperature of 30°C in a water bath) to grow for 10 minutes, and then turn off the hydrogen and the precursor Passing in, passing argon gas at a flow rate of 1200 ml / min into the chemical vapor deposition furnace for cleaning and pushing the sample to a low temperature zone. Under the protection of this atmosphere, the temperature of the reaction ...

Embodiment 2

[0041] After raising the temperature of the chemical vapor deposition furnace to 800°C, place the p-type silicon wafer sputtered with a 50nm silicon oxide film in the low-temperature area of the furnace tube of the reaction furnace, seal the tube furnace, vacuumize to about 10Pa, and then pump at 100ml / min Hydrogen at a flow rate of 200 ml / min and argon at a flow rate of 200 ml / min are fed until normal pressure is restored. Then, push the silicon wafer to a constant temperature zone of 800°C for heat treatment for 20 minutes; then change the flow rate of 100 ml / min to the argon-carried precursor (acetonitrile, kept at a constant temperature of 40°C in a water bath) to grow for 20 minutes, and then turn off the hydrogen and precursors. 1200 ml / min flow of argon gas was introduced into the chemical vapor deposition furnace for cleaning and the sample was pushed to the low temperature zone. Under the protection of this atmosphere, the temperature of the reaction furnace was slo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com