In vitro regeneration countercurrent ion exchange system and method of use

An ion exchange and in vitro regeneration technology, applied in ion exchange, ion exchange regeneration, ion exchange water/sewage treatment and other directions, can solve the problems of low water saving rate, inability to continuously produce water, high consumption of regeneration liquid, and achieve energy saving and time, to ensure the quality of continuous water production, the effect of stable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

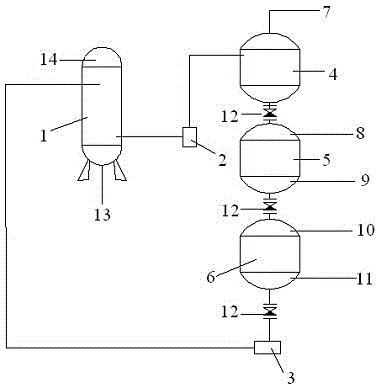

[0032] The in vitro regenerative countercurrent ion exchange system includes an ion exchanger, an ejector, a collection tank, a regeneration tank, and a cleaning tank; the ion exchanger, ejector, collection tank, regeneration tank, and cleaning tank are connected in sequence, and the collection tank The bottom is connected to the top of the regeneration tank, the bottom of the regeneration tank is connected to the top of the cleaning tank, the bottom of the cleaning tank is connected back to the ion exchanger, and an injector is arranged between the cleaning tank and the ion exchanger; the collecting tank The upper part is provided with a water outlet, the lower part of the regeneration tank is provided with a liquid inlet, and the upper part is provided with a liquid discharge port, the lower part of the cleaning tank is provided with a water inlet, and the upper part is provided with a drain port.

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, on this basis:

[0035] The water inlet of the ion exchanger is at the bottom of the exchanger, and the water outlet is at the upper part of the exchanger.

[0036] The ion exchanger is provided with two sampling points, one at the tank outlet and one at the 2 / 3 of the tank. The user needs the indicator to be tested at the tank outlet, and the 2 / 3 test indicator of the tank is the set indicator. When the hardness is just lower than the user's indicator, increase the flow rate of the recycled resin (control the flow rate of the injector) or reduce the flow rate of the raw water.

Embodiment 3

[0038] This embodiment is basically the same as Embodiment 1, on this basis:

[0039] The water inlet of the ion exchanger is at the bottom of the exchanger, and the water outlet is at the upper part of the exchanger.

[0040] The water outlet of the collection tank is connected to the liquid storage container, and the liquid storage container is connected to the water inlet of the cleaning tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com