Automatic feeding device for core ring punching and based on rotary grinding wheel forming machine

An automatic feeding, rotary technology, applied in the direction of conveyor objects, transportation and packaging, and object destacking, etc., can solve the problems of high labor intensity, personal injury accidents, fatigue, etc., to improve production efficiency and avoid personal injury. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

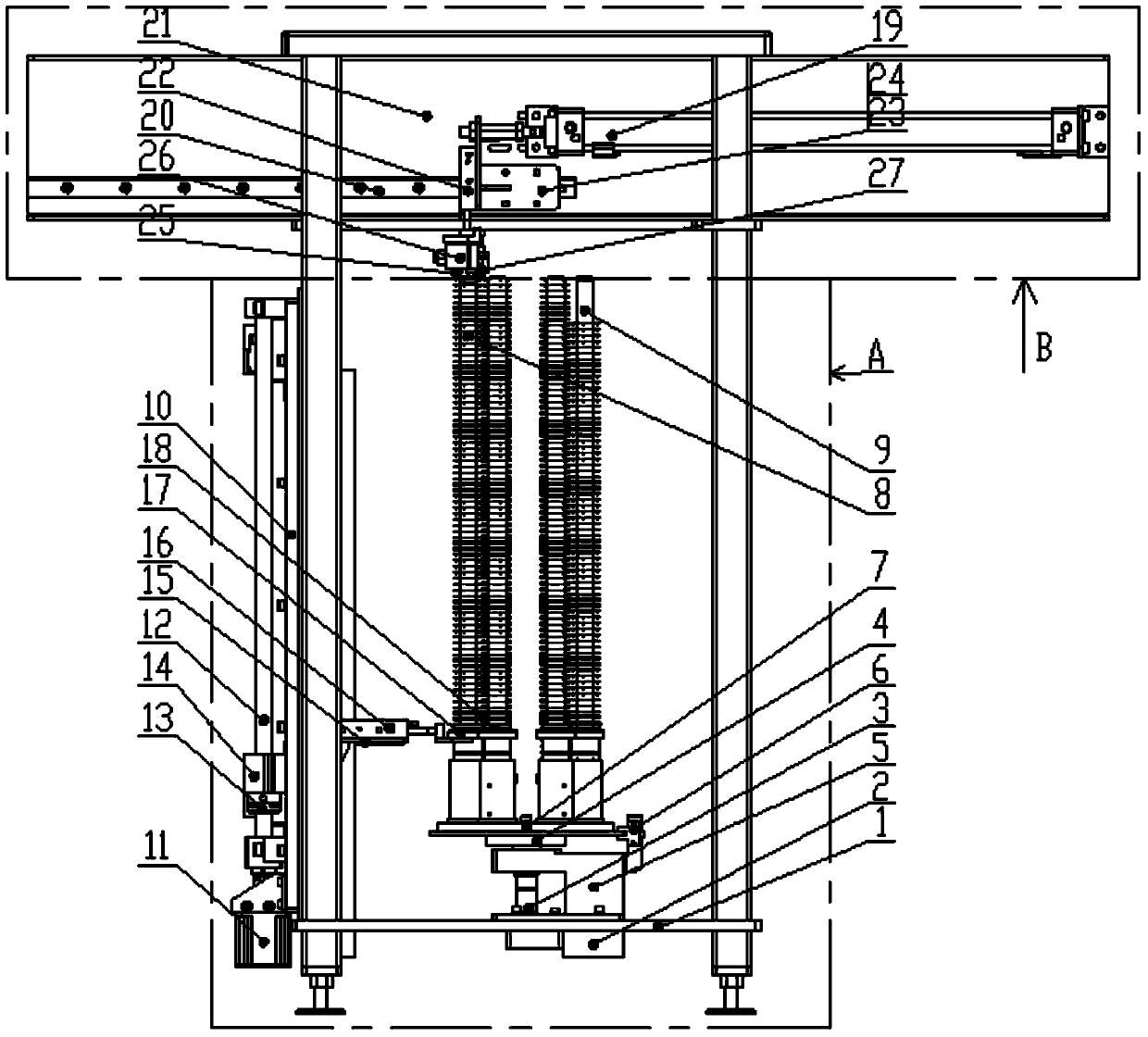

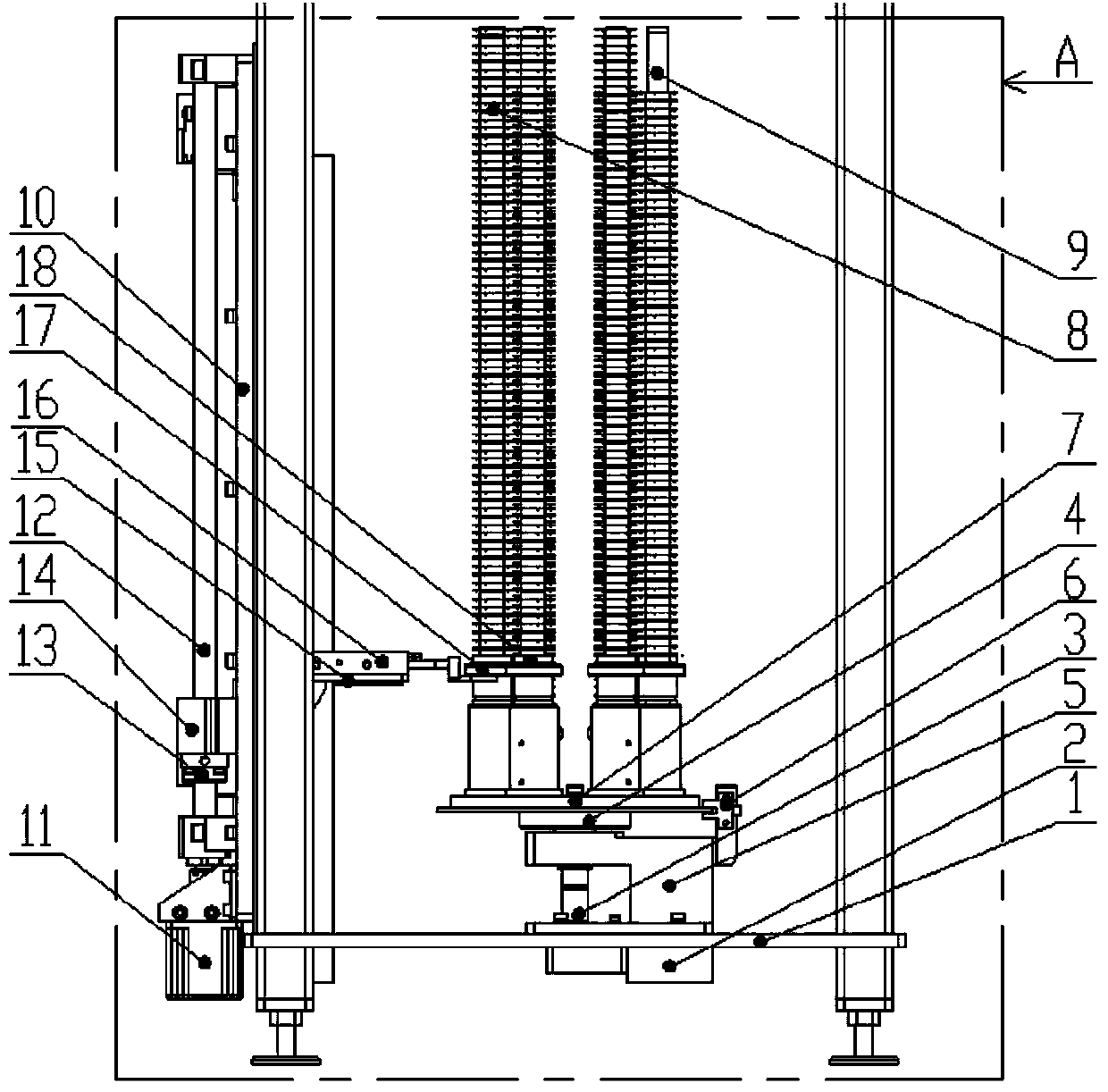

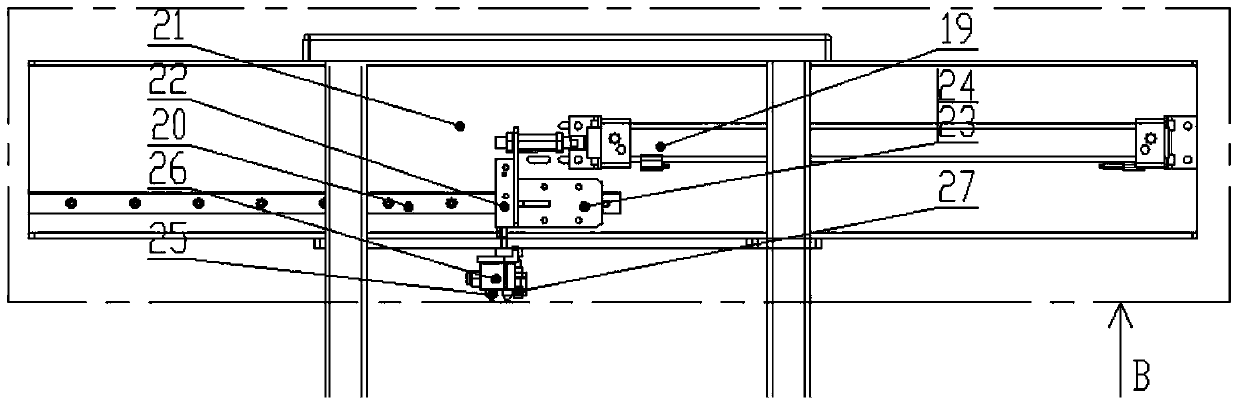

[0029] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a main frame body 1, on which a turntable core ring stack is installed, and on the side of the main frame body 1 there is a device for driving the core rings to move upward along the column to realize The vertical lift-type core ring conveying mechanism with the core ring conveying function; the core ring lifting device in the vertical lift-type core ring conveying mechanism is matched with the turntable core ring stack; There is a horizontal reciprocating core ring feeding mechanism, and the horizontal reciprocating core ring feeding mechanism is used to place the core rings on the turntable core ring stack into the stamping station of the grinding wheel forming machine, so as to complete the automatic loading of the core rings Material task.

[0030] exist figure 2 Among them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com