Spray guns for desulfurization and denitrification

A technology of desulfurization, denitrification, and spray gun, which is applied in the direction of spraying device, liquid spraying device, gas treatment, etc. It can solve the problems that affect the safety of equipment operators, the fluid cannot be sprayed with granularity, and the mixing effect cannot be achieved, so as to reduce the operating requirements. , Simplify the trouble of control, improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

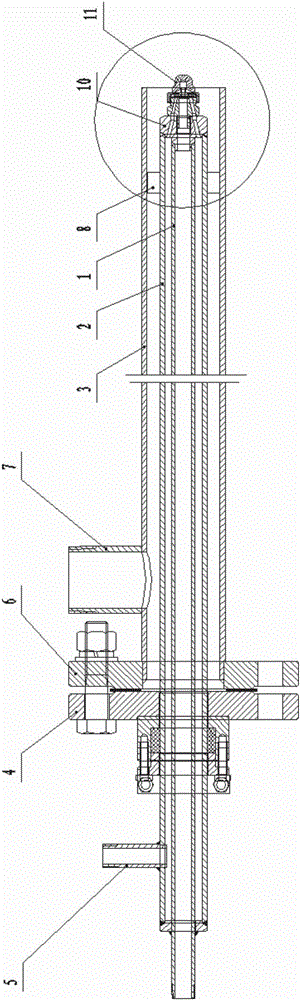

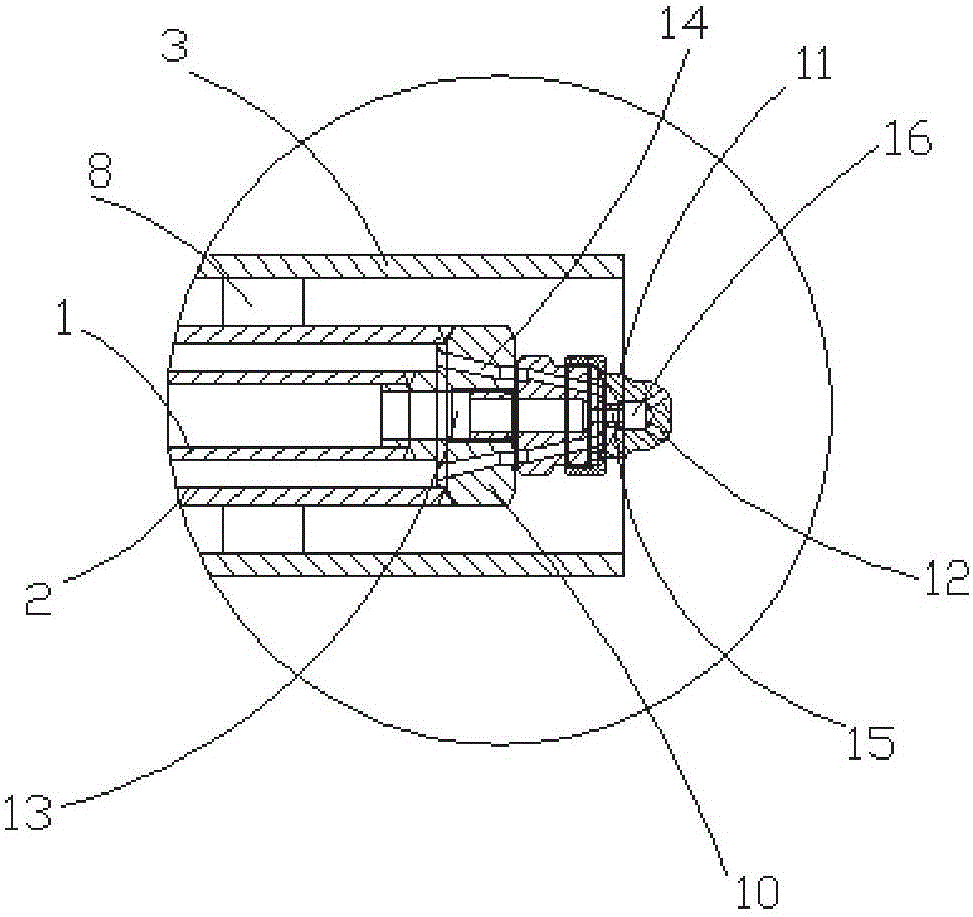

[0021] like figure 1 and figure 2 As shown, the present invention relates to a spray gun for desulfurization and denitrification, which is characterized in that: it includes an inner tube 1, a middle tube 2 and an outer tube 3 arranged sequentially from the inside to the outside, and one end of the middle tube 2 is connected to the inner tube 3. The outer wall of the tube 1 forms a sealed and fixed connection, and the other end and one end of the inner tube 1 jointly form a nozzle assembly, and the outer wall of the middle tube 2 is provided with a movable flange 4 and an air intake pipe 5; the outer wall of the outer tube 3 There is a fixed flange 6 matched with the movable flange 4 on the top, a connection pipe 7 is provided on the outer wall of the outer tube 6 , and support blocks 8 distributed around the circumference are formed between the inner wall and the middle tube 2 .

[0022] In order to improve the spraying effect, the nozzle assembly in the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com