Semiconductor device and method for producing same

A manufacturing method, a semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve the problem of carrier mobility reduction, achieve low-cost manufacturing methods, improve the increase of on-resistance, stabilize and manufacture The effect of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

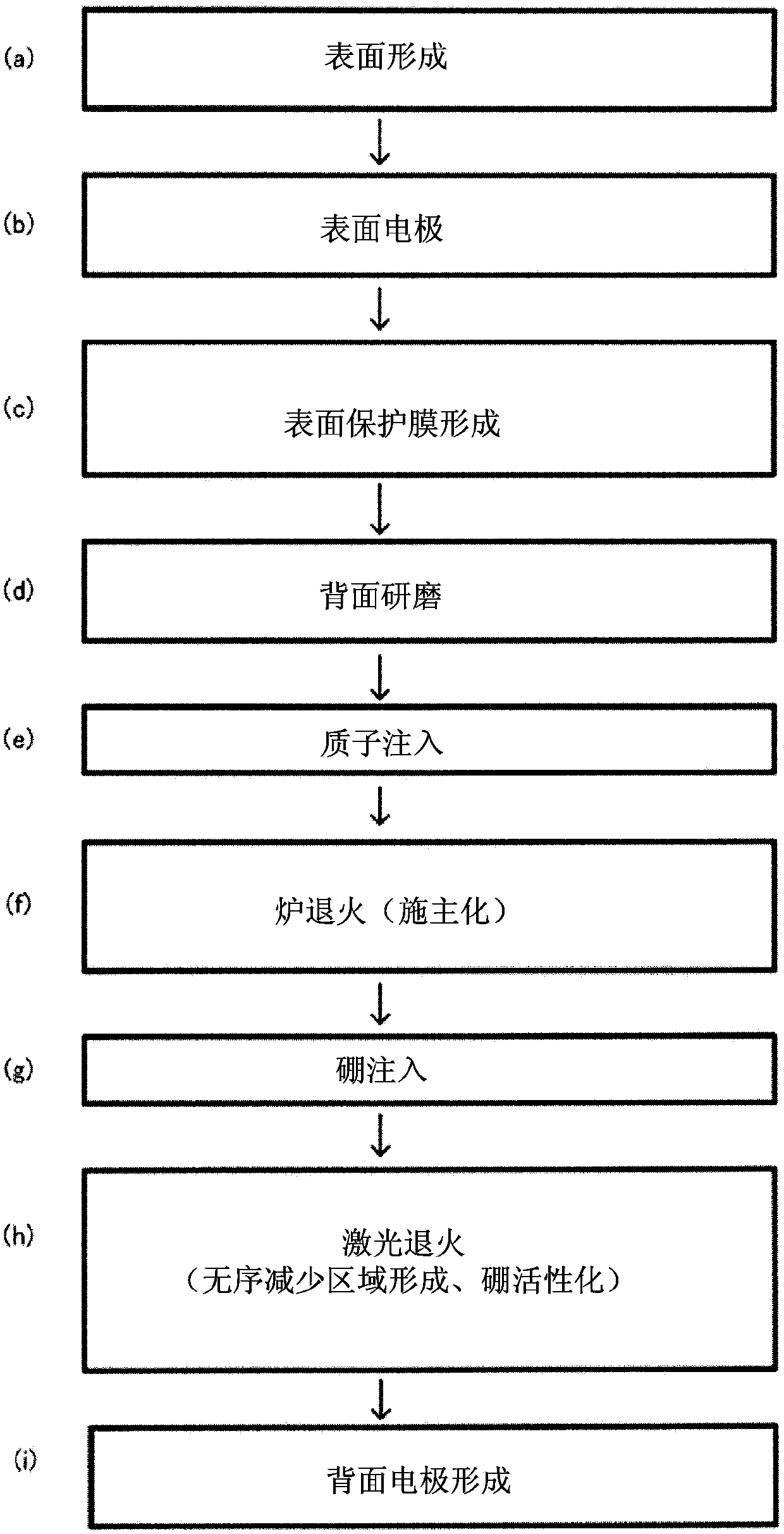

[0057] figure 1 It is a process flow chart showing the manufacturing method of the semiconductor device (IGBT100) of Example 1 of this invention. image 3 is used figure 1 The cross-sectional view (a) of the main part of the IGBT100 produced in the process flow of FIG. refer to figure 1 process flow and image 3 (a) is a cross-sectional view of main parts to describe the method of manufacturing the semiconductor device according to the first embodiment of the present invention.

[0058] First, in figure 1 In the surface forming step of (a), on one main surface (surface 11a) of n semiconductor substrate (wafer) 11, p base layer 22, n emitter layer 2, gate insulating film 23, gate electrode 24, and interlayer insulating film are formed. MOS gate structure composed of film 28 and so on. Wherein, the n-emitting layer 2 is formed in the p-base layer 22 . The configuration of the MOS gate structure will be described later.

[0059] Next, at figure 1 In the surface elec...

Embodiment 2

[0083] The semiconductor device of Example 2 will be described. Figure 4 It is a process flow diagram showing a method of manufacturing a semiconductor device according to Embodiment 2 of the present invention.

[0084] The difference from Example 1 is that after proton implantation, boron implantation ( Figure 4 (e) process), followed by laser annealing ( Figure 4 (f) process) and subsequent furnace annealing treatment ( Figure 4 (g) process). At this time, in the previous laser annealing process, the protons generated in the proton implantation 16 pass through the region 14 to form the n-type disorder-reducing region 18 while activating boron to form the p-collector layer 4 . In addition, in the furnace annealing treatment performed in the subsequent step, protons are donated to form the n-type field stop layer 3 . Also in this case, as in Example 1, by combining the laser annealing treatment and the furnace annealing treatment, the n-type disorder-reduced region 18 ...

Embodiment 3

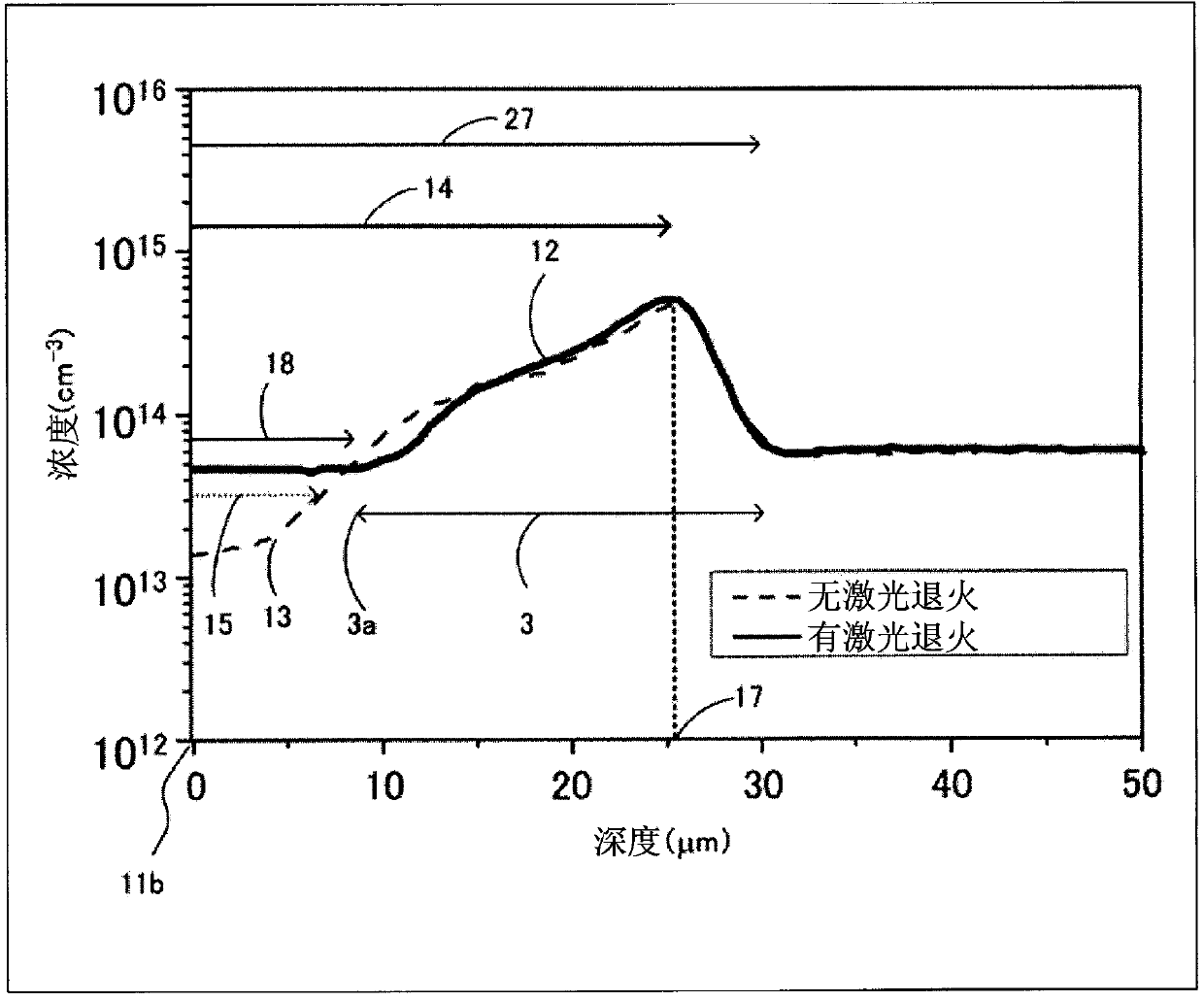

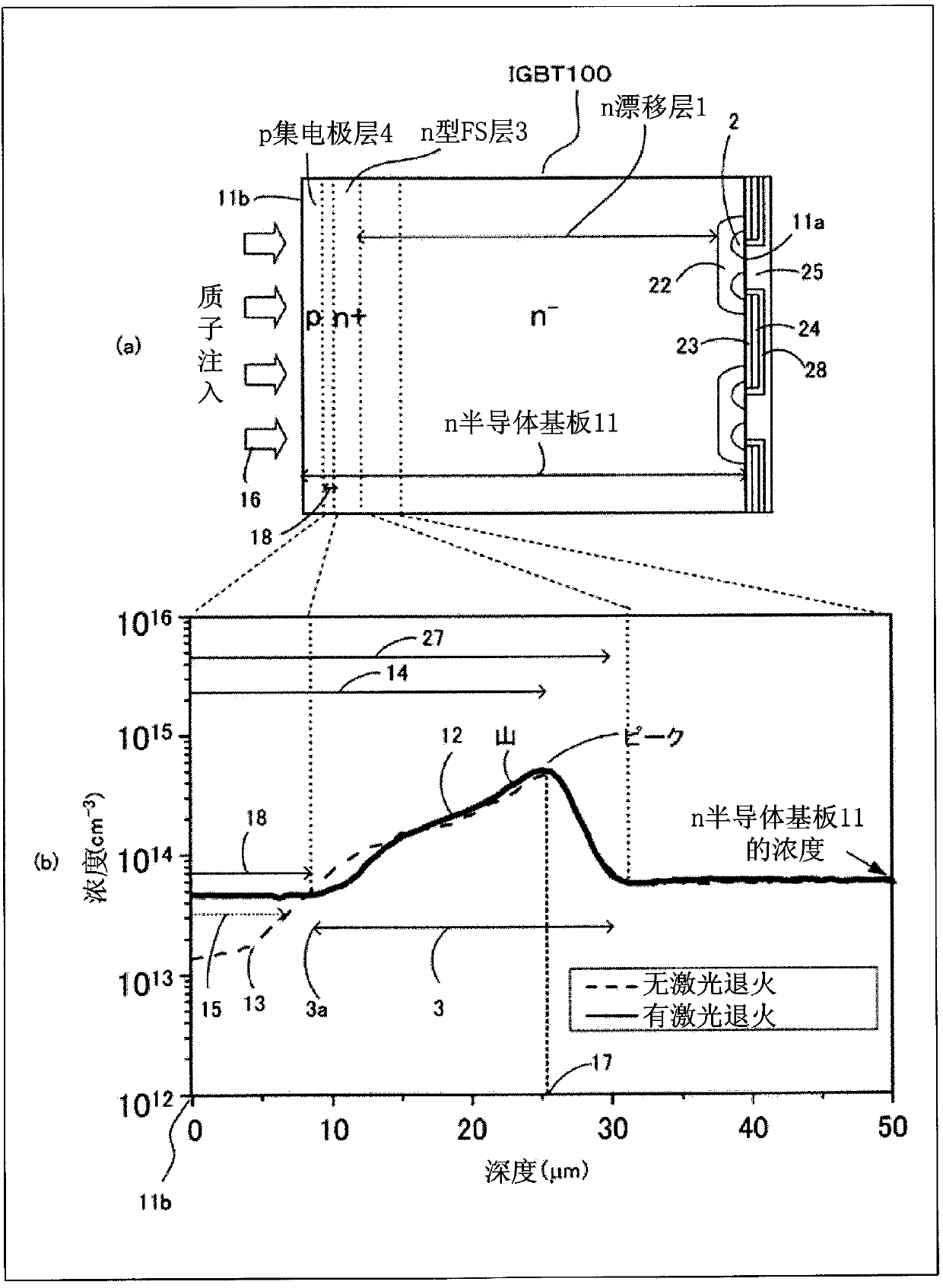

[0088] The semiconductor device of the third embodiment will be described. In Example 3, one or more n-type intermediate layers 27 consisting of a pair of n-type field stop layer 3 and n-type disorder reducing region 18 are formed, for example, an IGBT in which three are formed as in this example. Figure 5 It is a cross-sectional view (a) of a main part of a semiconductor device (IGBT100) according to Example 3 of the present invention and a graph of a carrier concentration curve (b) near the n-type field stop layer 3 . By forming a plurality of n-type intermediate layers 27 in this way, it is possible to relax the diffusion of the depletion layer at the time of turning off, and suppress the oscillation phenomenon at the time of switching (at the time of turning off).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com