Crown for an aircraft tire

A technology for tires and crown reinforcements, which is applied to the reinforcement layer of pneumatic tires, aircraft tires, tire parts, etc., and can solve problems that are not conducive to aircraft payloads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

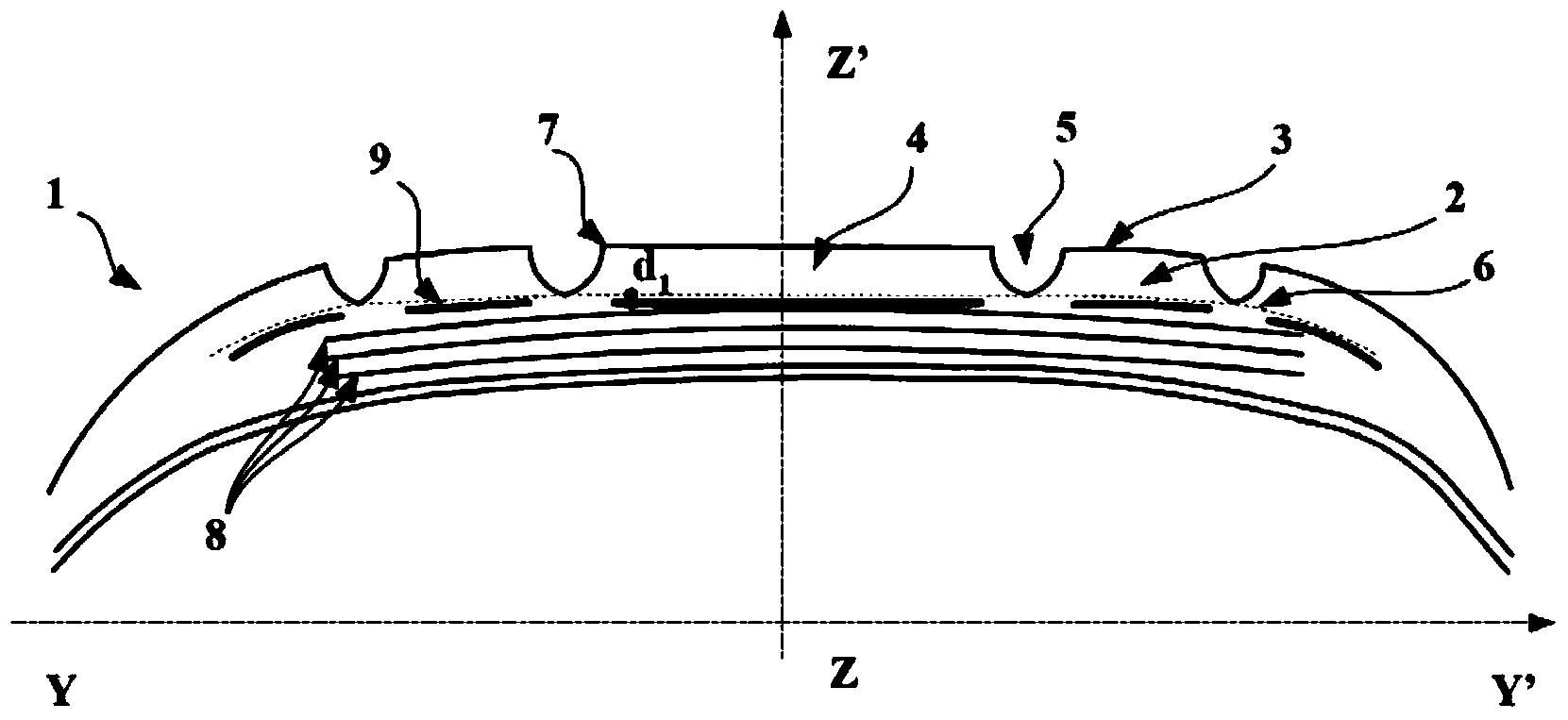

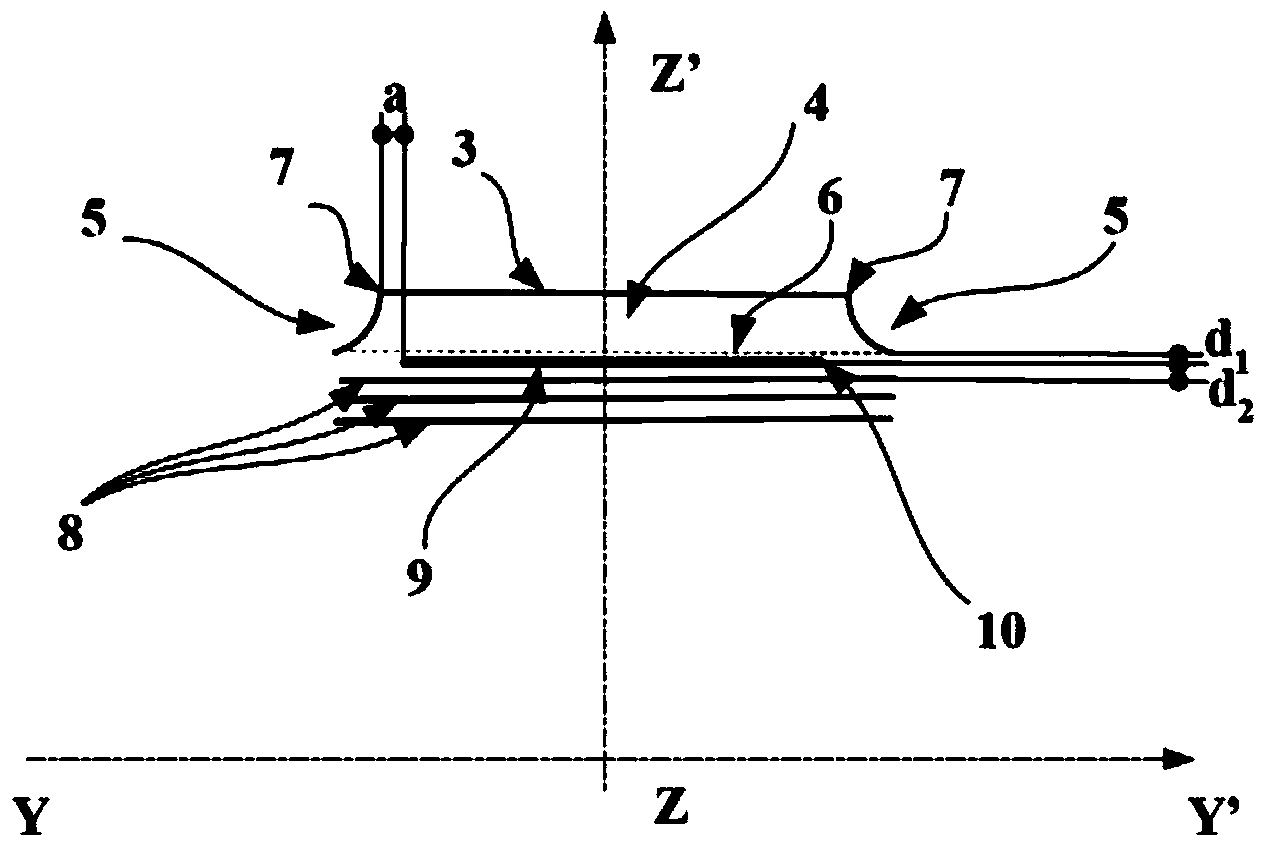

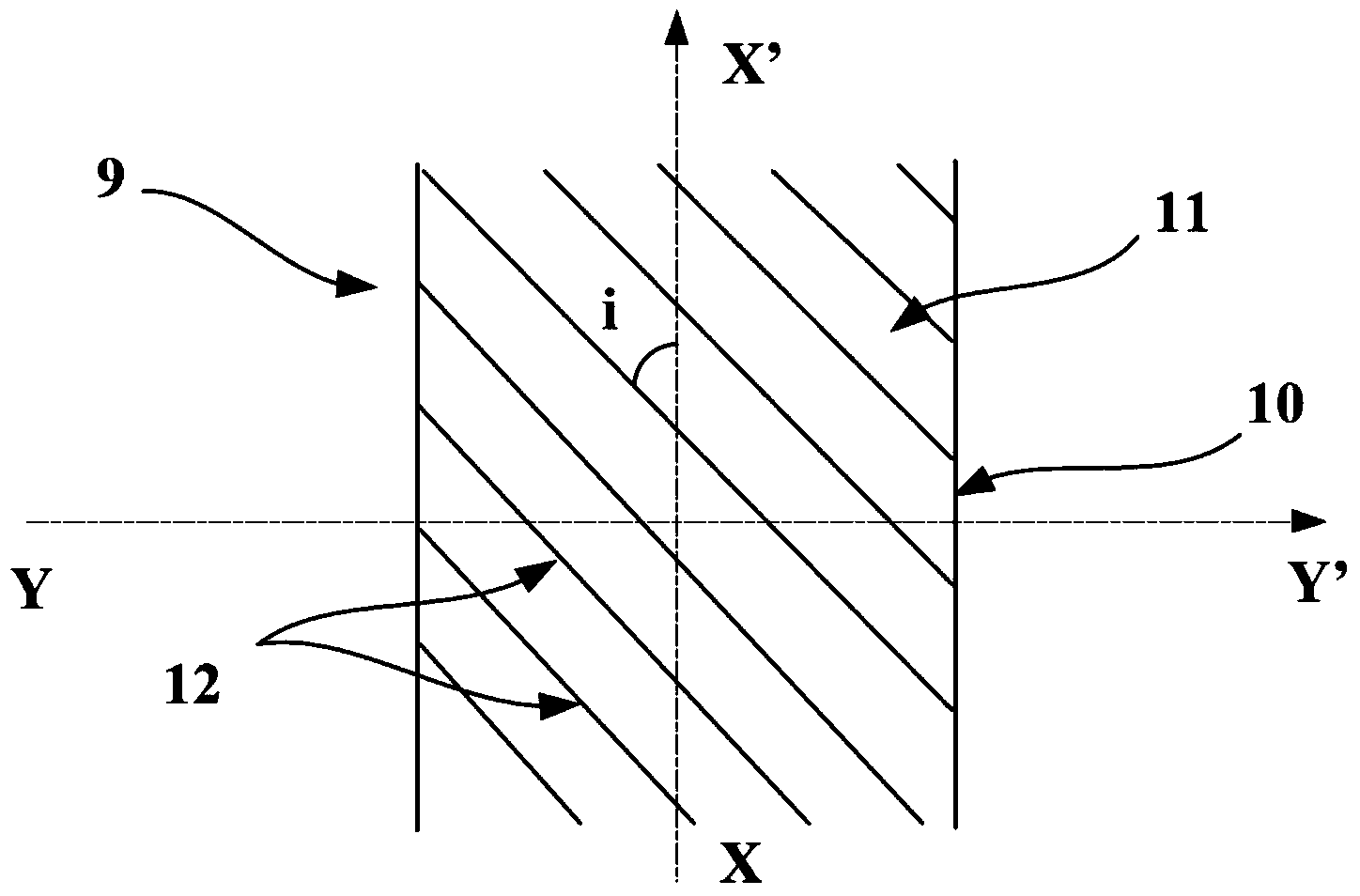

[0056] figure 1 A meridian section through the crown of the tire 1 is shown, ie a section in the meridian plane (YY', ZZ'), where the directions YY' and ZZ' are the axial and radial directions respectively. The direction XX' (not shown) is the circumferential direction. The plane (XX', ZZ') is the equatorial plane.

[0057] figure 1 A tire 1 for aircraft is shown comprising a tread 2 intended to come into contact with the ground via a tread surface 3 arranged radially between an underside 6 and the tread surface 3 . The tread 2 comprises at least 5 circumferential ribs 4 which, in this case, are adjacent to at least one circumferential groove 5 . Each circumferential rib 4 extends radially between the bottom surface 6 and the tread surface 3 and extends axially in the tread surface 3 between two edge corners 7 . the axially outermost shoulder circumferential rib is bounded axially on the inside by the edge corner and on the outside by the axial limit of the ground-contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com