A triple layer hydrophobic-hydrophilic membrane for membrane distillation applications

A membrane distillation, hydrophobic technology, applied in the field of three-layer composite nanofiber membrane, can solve the problem of not improving the hydrophobicity of the composite membrane, and achieve the effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

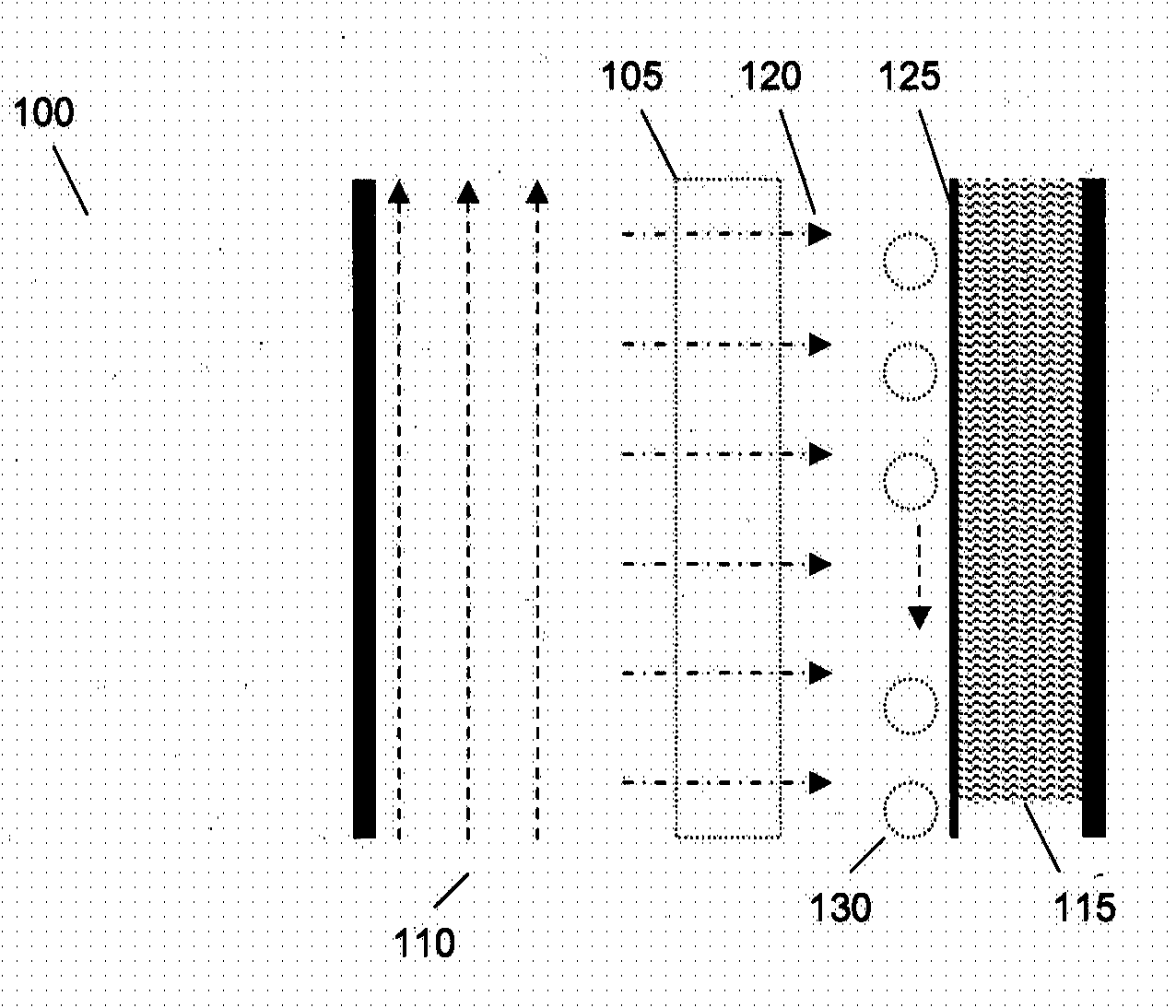

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] For material, 761 grade material PVDF (melting point 165°C to 172°C) was purchased from Arkema Pte. Ltd., Singapore. Technical grade material PVP-K17 was purchased from Shanghai Welltone Material Technology Co., Ltd, Shanghai, China, while analytical grade ethanol, acetone and N,N'-dimethylacetamide (DMAC) were purchased from Sigma, Singapore. The water used was distilled and purified with a Milli-Q plus system from Millipore, Bedford, MA, USA.

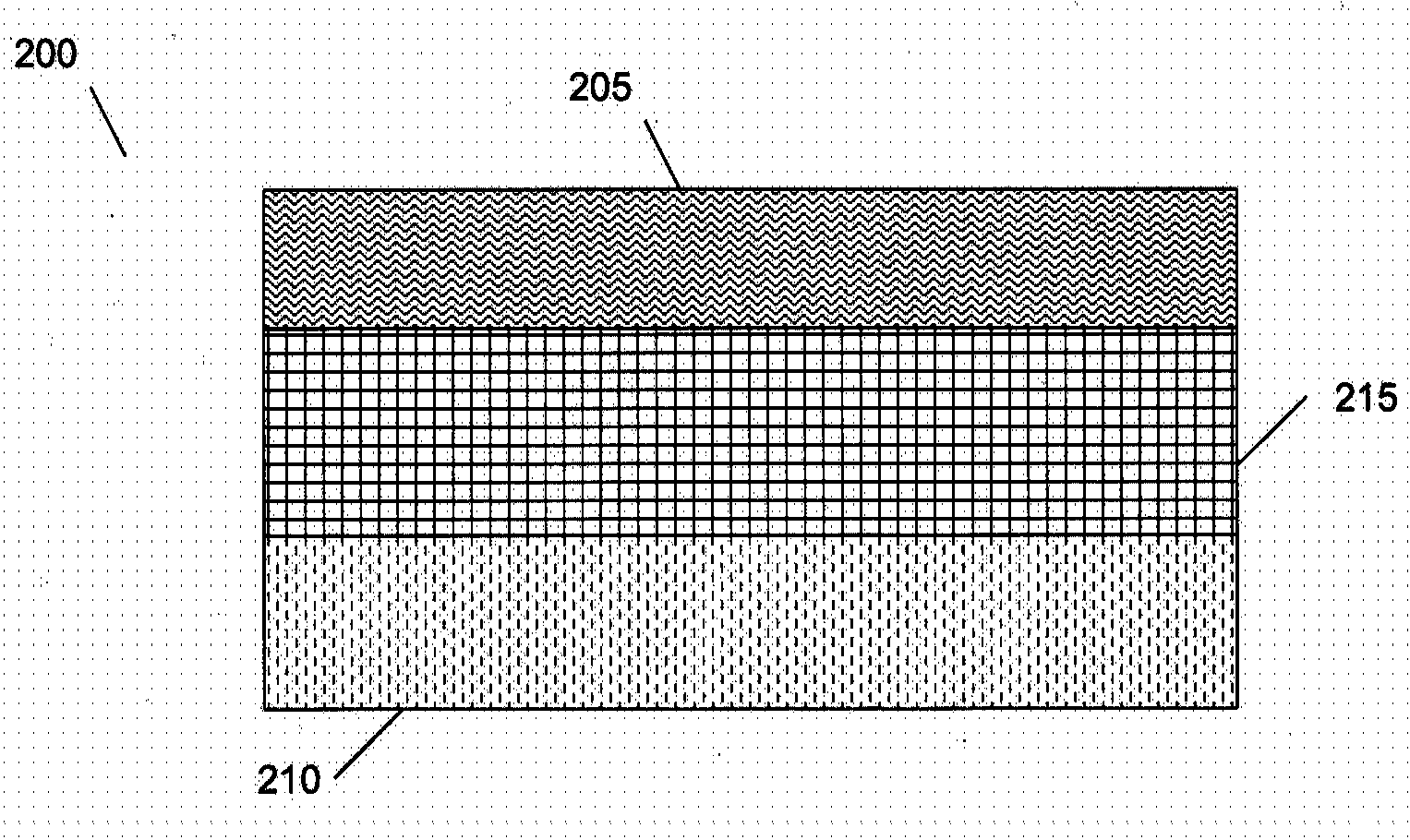

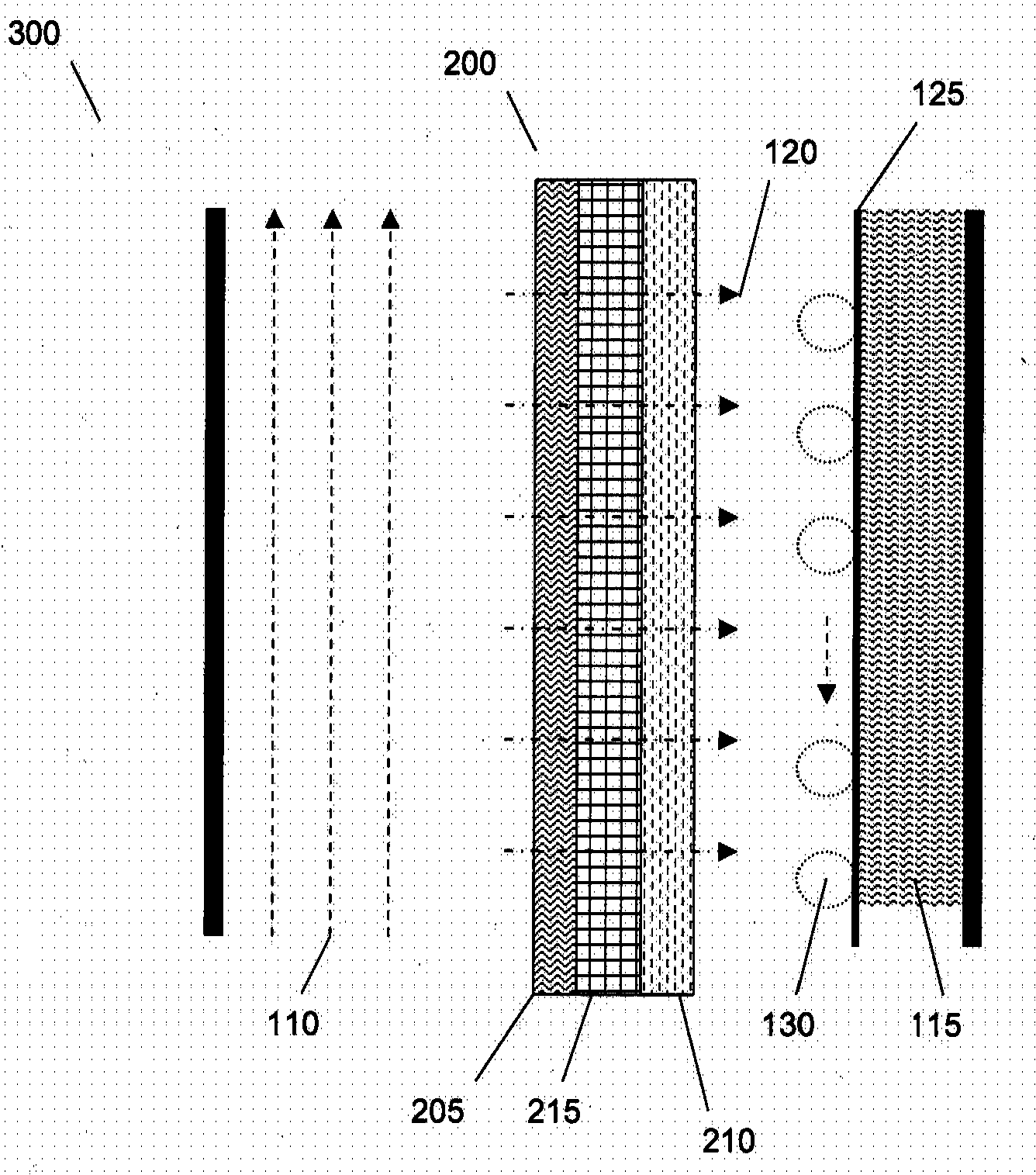

[0069] For the microporous layer cast onto the backing layer, the PVDF cast membrane was prepared by immersion precipitation method. Polyvinylidene fluoride polymer in dimethylacetamide (DMAC) can be used as a polymer dopant, and PVP-K17 can be used as an additive, while ethanol can be used as a non-solvent. The compositions of the casting solutions were 17 wt% of PVDF, 5 wt% of PVP, 2 wt% of ethanol and 76 wt% of DMAC. PVDF and PVP powders were added to the DMAC mixture, the ethanol solution was mixed in a RB three-neck fl...

Embodiment 2

[0078] In this embodiment, polydimethylsiloxane (PDMS) is added to the microporous layer 215 . Microporous layer 215 comprises a PVDF-PDMS membrane that can be cast onto a backing layer. These PVDF-PDMS membranes can be prepared by blending and immersion precipitation methods. Polyvinylidene fluoride and poly(dimethylsiloxane) in dimethylacetamide (DMAC) can be used as polymer dopants, and PVP-K17 can be used as an additive while ethanol is used as a non-solvent . The composition of the casting solution contained 17wt% of PVDF, 5wt% of PVP, 2wt% of ethanol, 0wt% to 6wt% of PDMS and 70wt% to 76wt% of DMAC. PVDF and PVP powders were added to the mixed DMAC, PDMS and deionized water solution in a RB three-neck flask, and the solution was mechanically stirred at 80°C for at least 48 hours to ensure complete dissolution of the polymers. The polymer solution was cast by immersion precipitation at room temperature. Then, the PVDF-PDMS dopant solution was cast on a glass plate by ...

Embodiment 3

[0090] In this embodiment, in the Figure 6 In step 620 of the illustrated electrospinning setup, additives are added to liquid polymer 502 . The liquid polymer 502 with additives is then used to produce a nanofiber mat. In one embodiment of the invention, a clay additive is added to the liquid polymer 502 containing PVDF.

[0091] Figure 17 The contact angles of nanofiber mats 1705, 1710, 1715, and 1720 over time are shown. A nanofiber mat 1705 was produced using a liquid polymer containing 12 wt% PVDF, and a nanofiber mat 1710 was produced using a liquid polymer containing 12 wt% PVDF with the addition of 2 wt% clay. Nanofiber mat 1715 was produced using a liquid polymer containing 12 wt% PVDF with 4 wt% clay added, and nanofiber mat 1720 was produced using a liquid polymer containing 12 wt% PVDF with 8 wt% clay added. The figure shows that as the concentration of the clay additive in the liquid polymer 502 increases, the contact angle of the nanofiber mat also increase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com