Rotor salient pole type hybrid excitation motor based on magnetic gear

A technology of hybrid excitation motor and salient pole type, which is applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, etc. Problems such as the mechanical strength of the rotor and the inability to adjust the air gap magnetic field have achieved the effects of compact structure, reduced volume, and reduced magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further explained below in conjunction with the accompanying drawings.

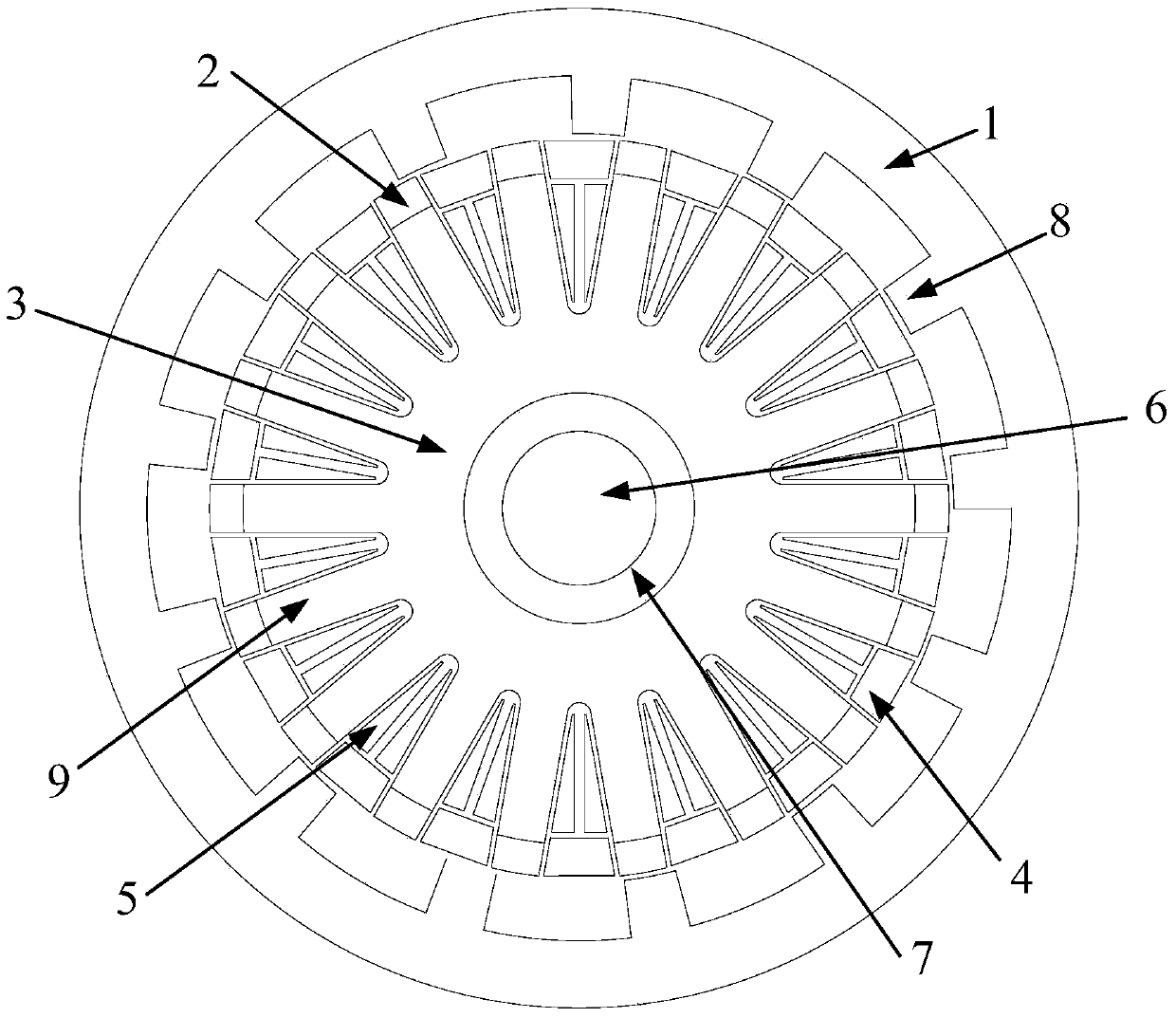

[0030] A rotor salient pole type hybrid excitation motor based on a magnetic gear includes an outer rotor 1 , a permanent magnet 2 , a stator 3 , an excitation winding 4 , an armature winding 5 , a support shaft 6 and a bearing 7 . The material of the outer rotor 1 is silicon steel sheet and is rotationally connected with the motor support shaft 6 through the bearing 7. The outer rotor salient poles 8 arranged equidistantly are arranged on the inner ring of the outer rotor 1 . The material of the stator 3 is a silicon steel sheet and is fixedly arranged by the motor support shaft 6 , and the stator teeth 9 of the stator 3 adopt a parallel tooth structure. The permanent magnet 2 is made of NdFeB, and is attached to the surface of the stator tooth 9 of the stator 3; the permanent magnet 2 adopts a radial magnetization method, and each permanent magnet has the same size a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com