Safety assessment method for pressure-bearing structure with creep damages and volume defects

A pressure-bearing structure and volumetric technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as high temperature creep damage, plane defects, etc.

Active Publication Date: 2014-08-20

EAST CHINA UNIV OF SCI & TECH

View PDF6 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In my country, a number of patents have disclosed methods for safety assessment of high-temperature and high-pressure equipment, such as Chinese patent CN201010130569 "Safety control method for pressure pipelines containing incomplete penetration defects under internal bending and torsion complex loads", CN

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

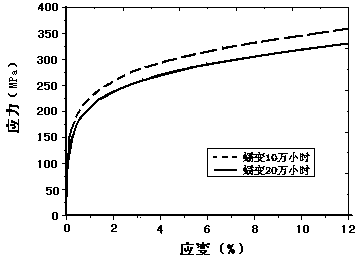

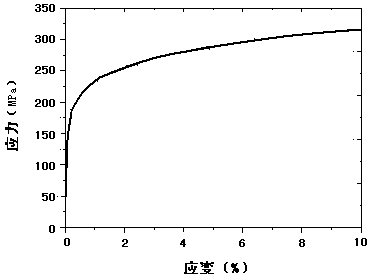

The invention relates to a safety assessment method for a pressure-bearing structure with creep damages and volume defects. The safety assessment method comprises the following steps of (1) establishing an elastoplastic constitutive model for the pressure-bearing structure working for a long time in order to predicate elastoplastic response of the pressure-bearing structure and make a preparation to estimate bearing limit of the pressure-bearing structure; (2) doing research on an expansion process and a failure mode of a plastic range of the pressure-bearing structure with various pits and local thinning defects under loading action of internal pressure or bending moment through a finite element method, doing research on influence of different creep damages caused by various pits and local thinning defects on bearing limit of the pressure-bearing structure and calculating out a bearing limit value of the pressure-bearing structure quantificationally; (3) determining safety assessment steps and performing safety assessment on the pressure-bearing structure with the creep damages and/ or the volume defects. By means of the safety assessment method, effects of the creep damages and the volume defect dimensions are tightly combined for the first time to work out a safety assessment standard suitable for the pressure-bearing structure working for a long time under high temperature and high pressure. Therefore, the safety assessment method for the pressure-bearing structure with creep damages and volume defects has a clear physical meaning and is adaptive to projects.

Description

technical field [0001] The invention relates to a safety assessment method for high-temperature pressure-bearing structures, in particular to a method for safety assessment of high-temperature pressure-bearing structures after long-term service involving creep damage and volume defects. Background technique [0002] High temperature and high pressure processes are widely used in electric power, petrochemical, nuclear energy, aerospace and other industrial fields. Creep damage will inevitably occur in pressure-bearing structures that work for a long time under high-temperature and high-pressure conditions. In addition, volume-type defects such as slag inclusions, pits, and thinning often occur in pressure-bearing structures during manufacturing and work. These creep damages And volume defects will weaken the load-bearing limit of the pressure-bearing structure, bring safety hazards to the equipment, and may even cause accidents such as leakage and explosion. Equipment that c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F19/00

Inventor 王宁涂善东刘洪起

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com