Method for calculating and analyzing fatigue life of airplane structure welding spots

A fatigue life and analysis method technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problem of no solder joint fatigue life analysis method, etc., to achieve the effect of improving fatigue performance and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0027] An example of life calculation for a welded structure of a high maneuvering aircraft is given below.

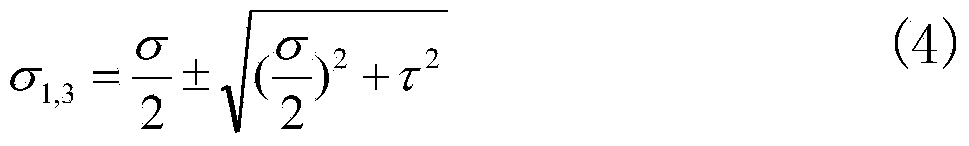

[0028] First, the welded structural stress of this type of aircraft is calculated by the finite element method

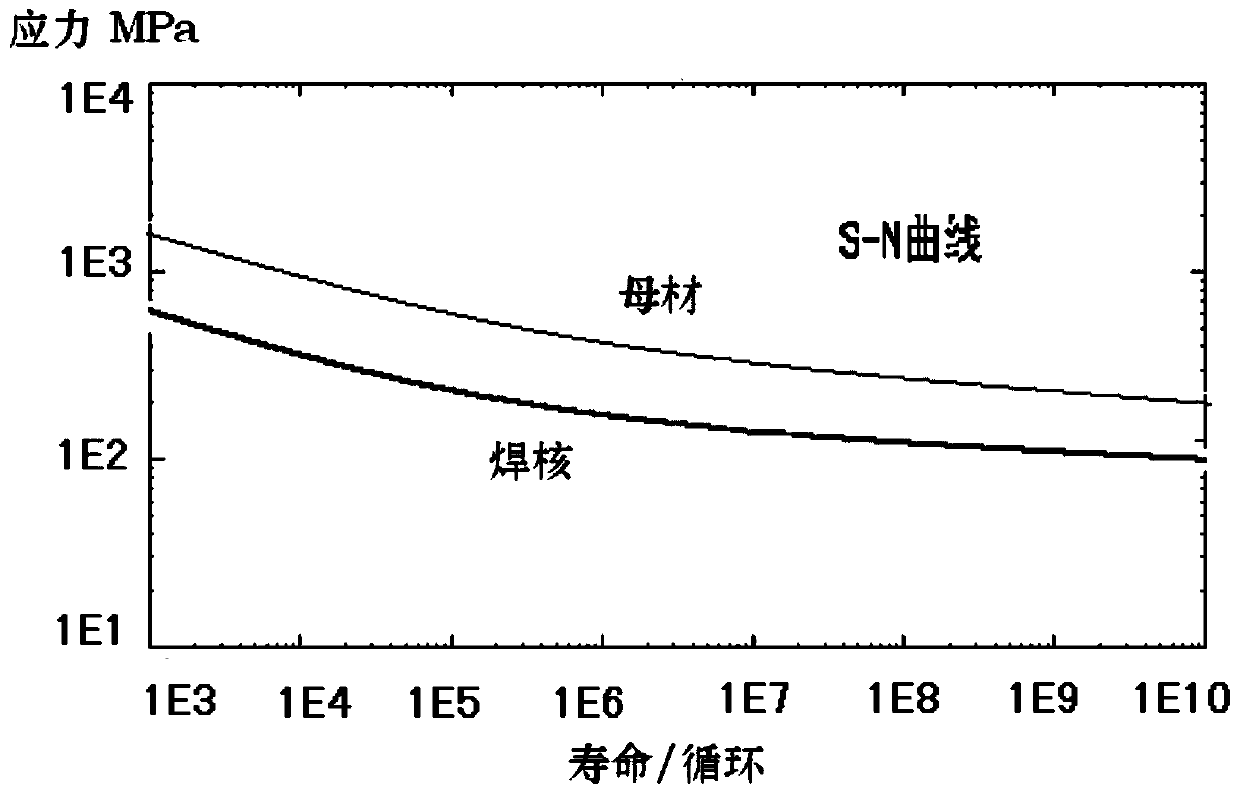

[0029] Second, the S-N curve of the weld nugget and base metal

[0030] The S-N curves of the weld nugget and the base metal are obtained through the material fatigue performance test.

[0031] Third, compile the stress spectrum of the welded structure of the high maneuvering aircraft

[0032] A basic spectrum block of the random spectrum of this type of aircraft consists of 15 typical subjects, a total of 142 takeoffs and landings, representing 186.52 flight hours. In order to ensure the integrity of the basic spectrum blocks, a spectrum with 13258 flight hours as a complete cycle was constructed, includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com