Method for performing position servo driving on electro-hydraulic proportional valve based on hybrid control

An electro-hydraulic proportional valve and hybrid control technology, applied to electric controllers, controllers with specific characteristics, etc., can solve problems such as high control accuracy, difficulty in achieving nonlinear systems, and inability to perform parameter compensation, so as to overcome system parameters. Drift, improve the effect on commands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

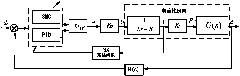

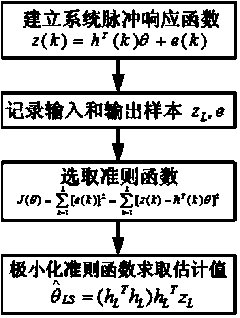

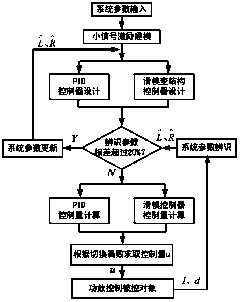

[0040] Specific implementation mode 1. Combination figure 1 , 2 And 3 illustrate this specific embodiment, a kind of electro-hydraulic proportional valve position servo drive method based on hybrid control, and it is realized by the following steps:

[0041] (1) The mathematical model of the electro-hydraulic proportional valve is established, including the system transfer function and state equation, which are used in the design of PID and sliding mode variable structure controllers respectively. The models are shown in formula 1 and formula 2.

[0042] System transfer function:

[0043] G p ( s ) = K Ls + R × 1 Ms + N - - - ( 1 )

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com