Water flow splitting device

A diverting device and water flow technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of large disturbance, decreased energy efficiency ratio, increased mixing of cold and hot water, etc., to reduce the impact of water flow, rational distribution and The effect of diversion and low mixing degree of cold and hot water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

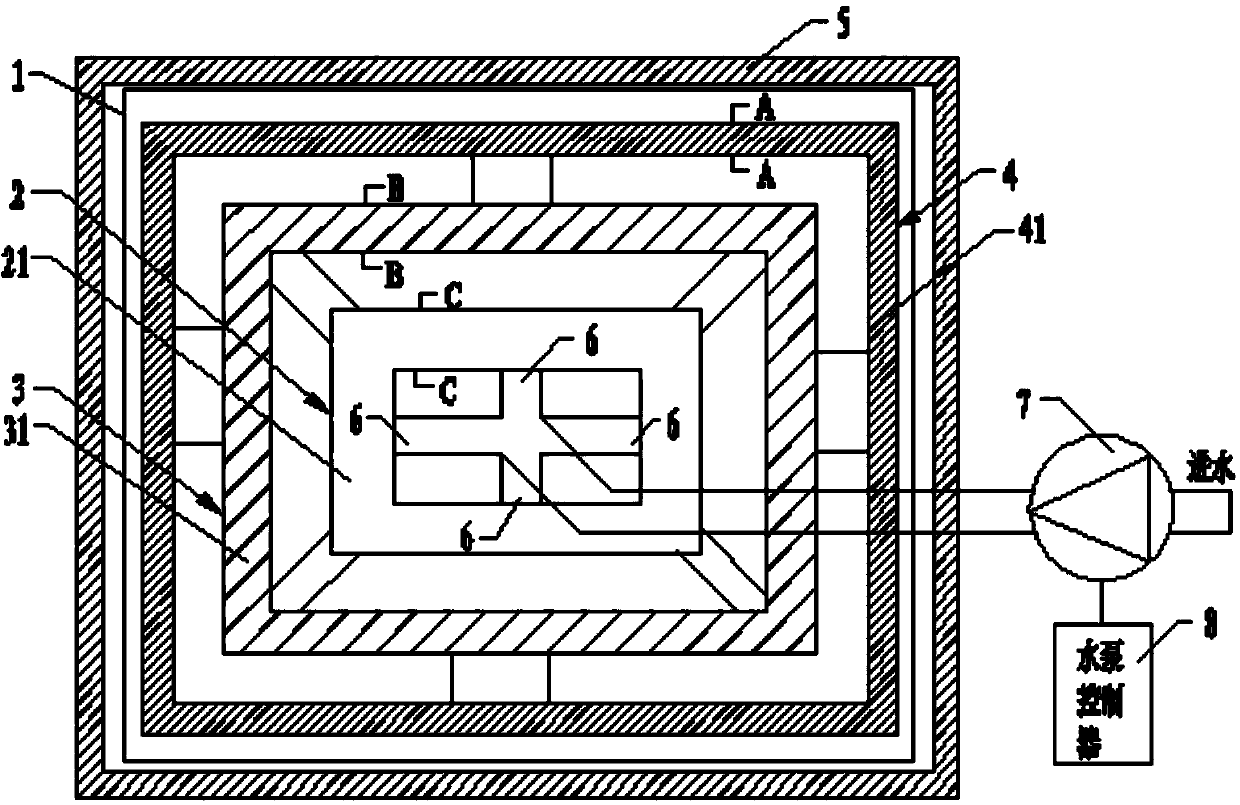

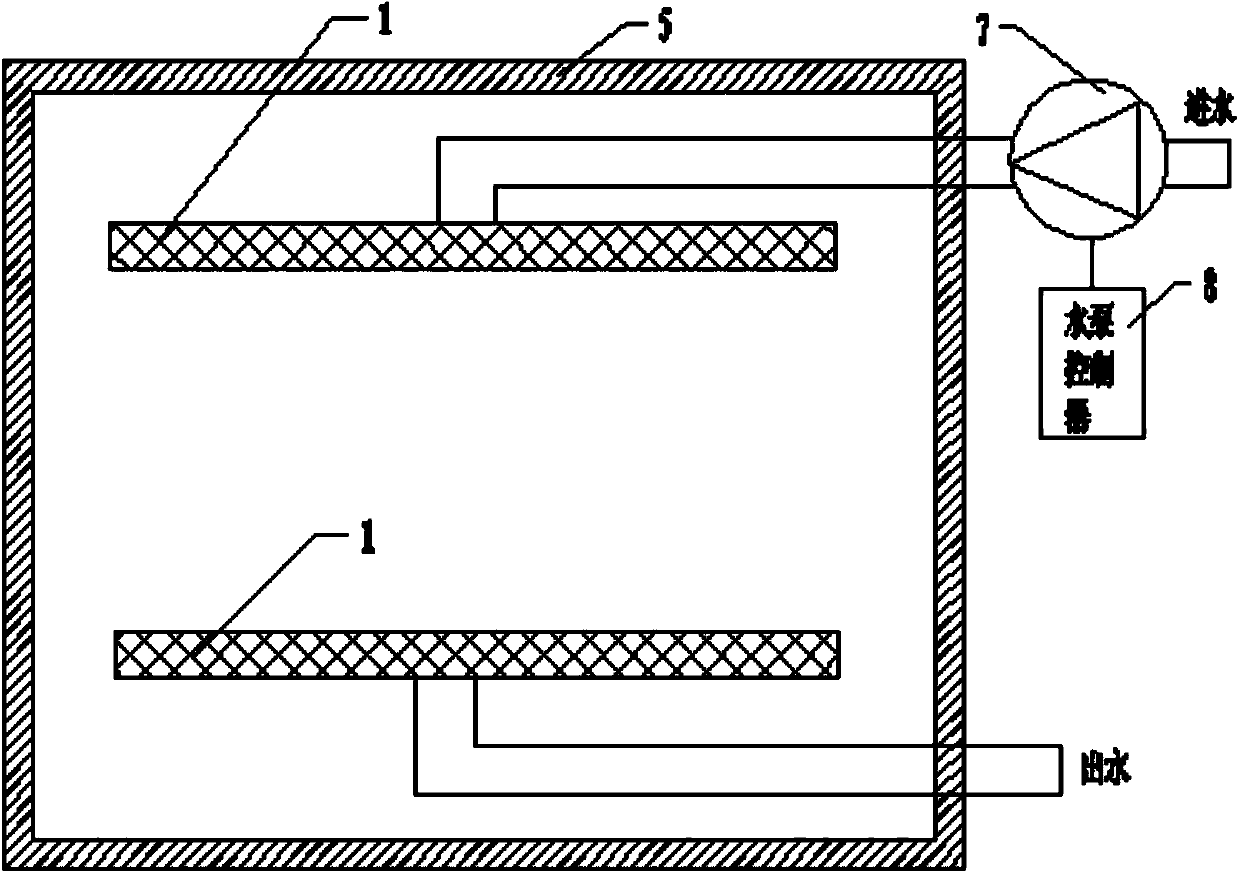

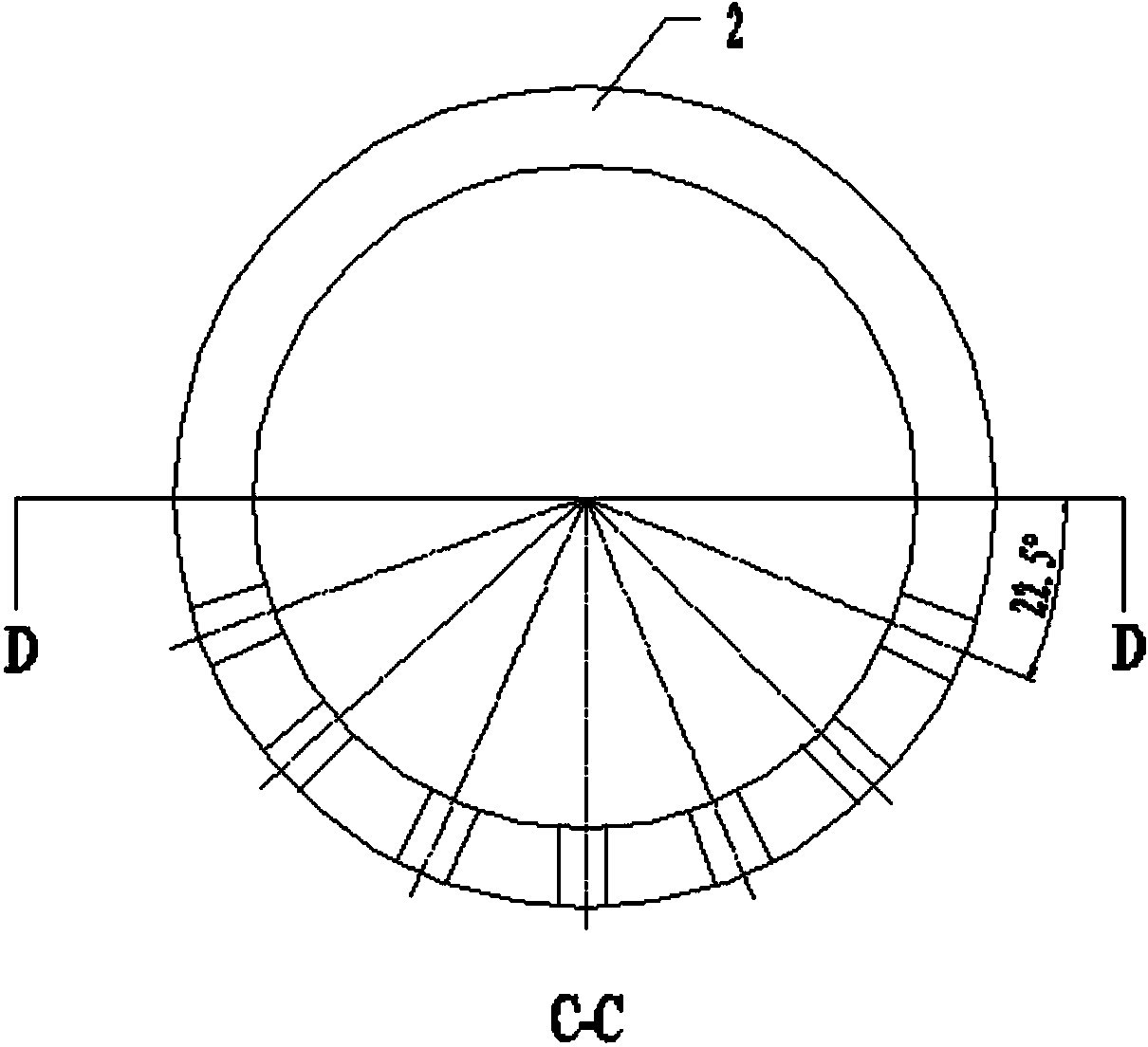

[0032] Such as Figure 1-2 The shown water distribution device 1 includes an internal water distributor 2, a middle water distributor 3, and an external water distributor 4; the internal water distributor 2 is a first rectangular frame surrounded by a first pipeline 21, and the first pipeline 21 is provided with 7 rows of small holes arranged in dislocations (such as image 3 with Image 6 As shown), the aperture of the small hole is preferably 0.5-1mm, and a water inlet 6 is provided in the middle of the four sides in the first rectangular frame. The middle water distributor 3 is a second rectangular frame surrounded by the second pipe 31, the second rectangular frame is arranged around the periphery of the first re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com