Expansion sealer

An expansion sealing and sealing disc technology, applied in lighting and heating equipment, fluidized bed combustion equipment, combustion methods, etc., can solve cracking, plastic deformation, and poor compensation ability of metal corrugated expansion joints at the interface between the slag discharge pipe and the furnace, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

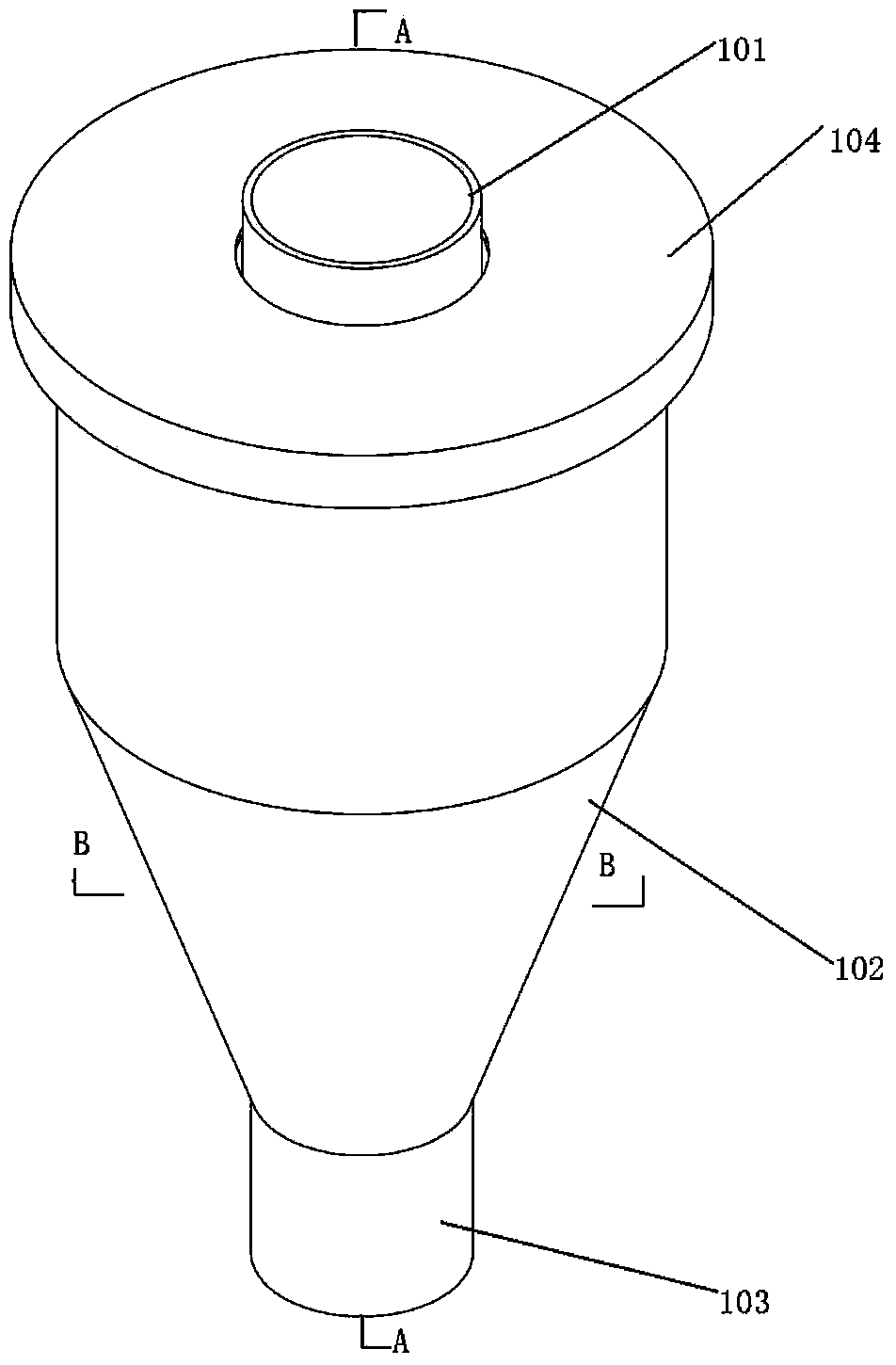

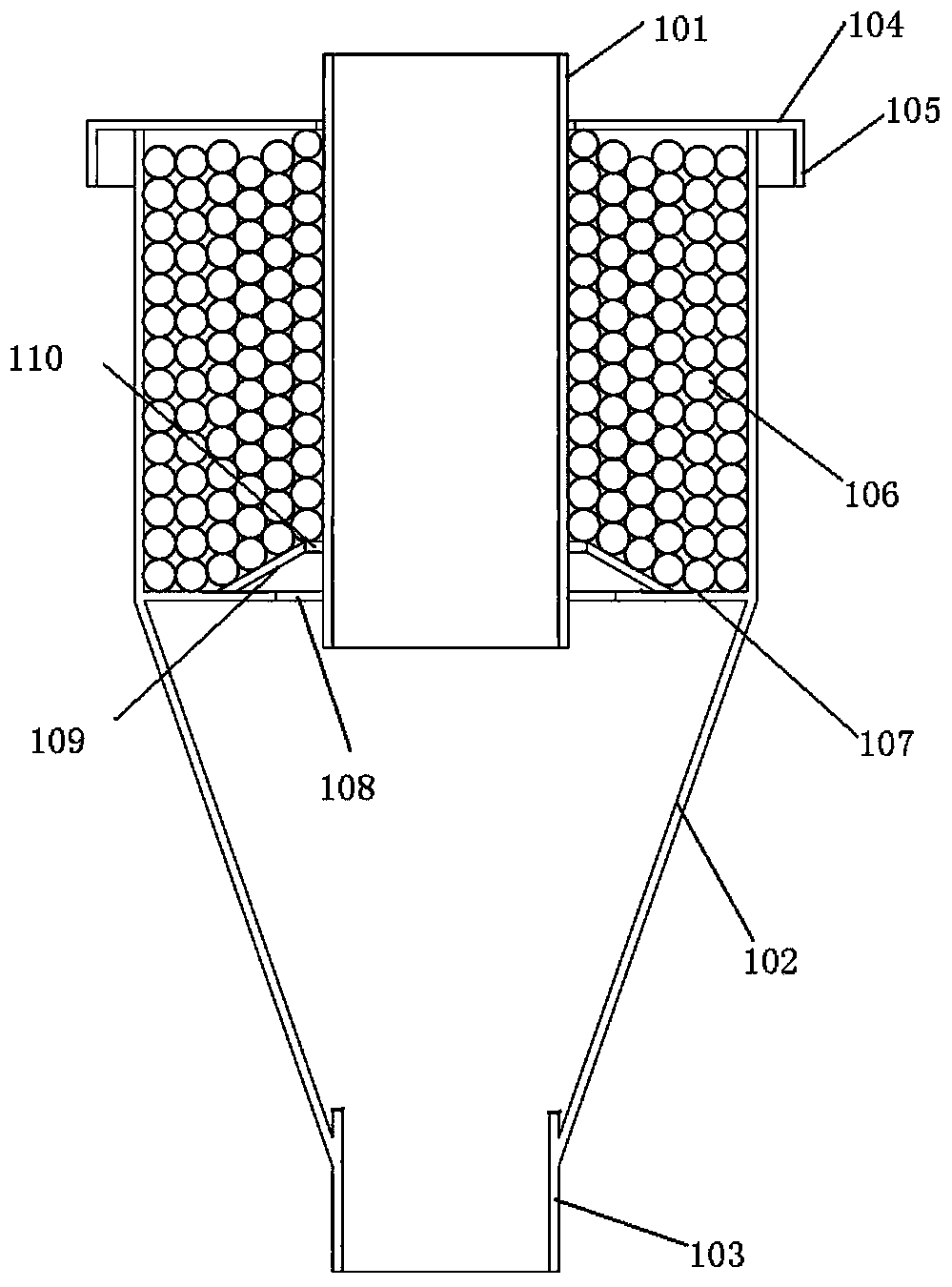

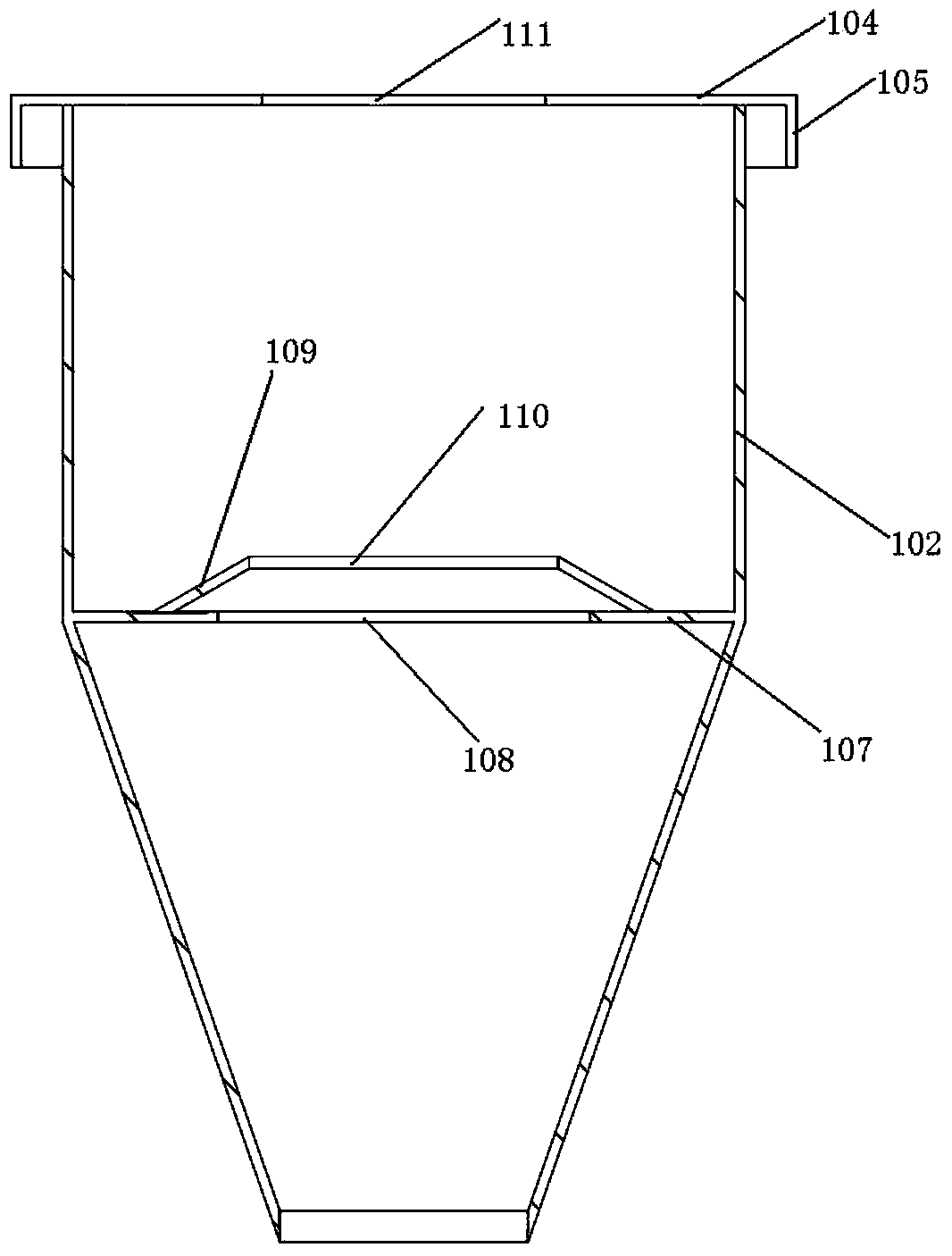

[0021] The present embodiment provides expansion seals, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes: a casing 102, an upper slag discharge pipe 101; the casing 102 is a hollow cavity with openings at both ends; one end of the upper slag discharge pipe 101 communicates with the furnace, and the other end passes through the opening of one end of the casing 102 and is arranged in the casing 102 The opening of the other end of the shell 102 communicates with the slag cooler; the shell 102 is provided with a fixed sealing disc 107, and the fixed sealing disc 107 is perpendicular to the extending direction of the shell 102; 101 passes through the expansion hole 108, and there is a gap between the edge of the expansion hole 108 and the upper slag discharge pipe 101; the fixed sealing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com