Packing Leakage Protection of Reciprocating Piston Compressor Gas Distribution Station

A technology of reciprocating pistons and compressors, applied in the field of gas distribution stations, can solve the problems of difficult installation of piping, pollution of lubricating oil, hidden safety hazards, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

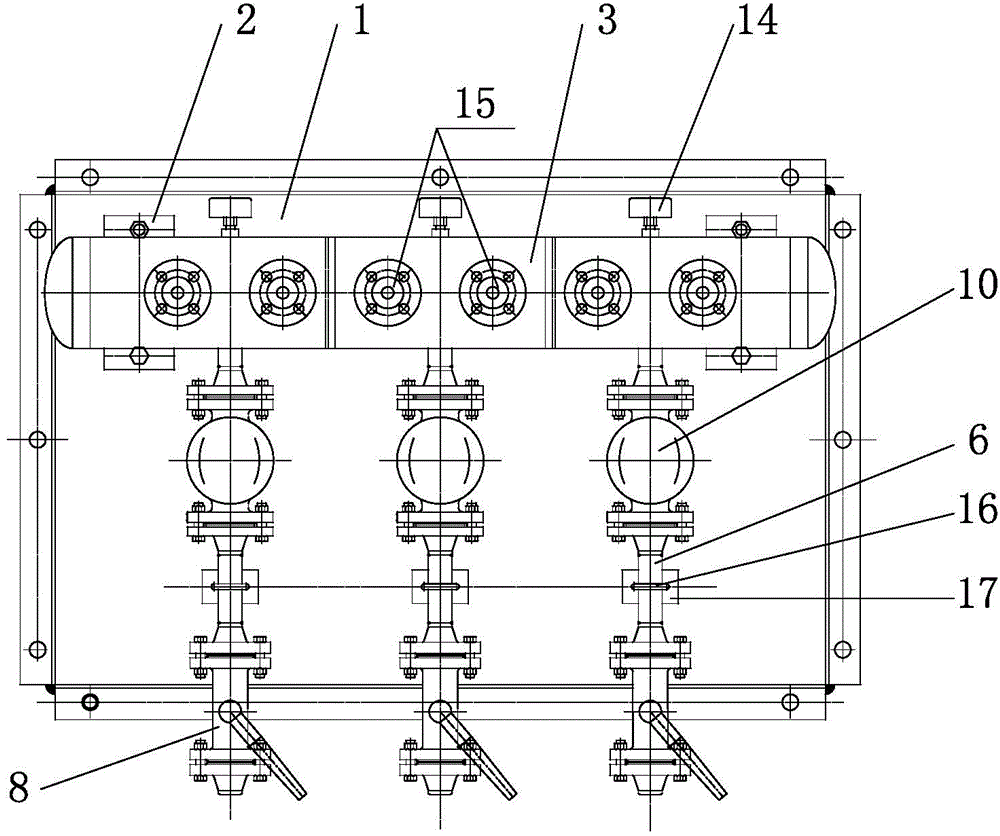

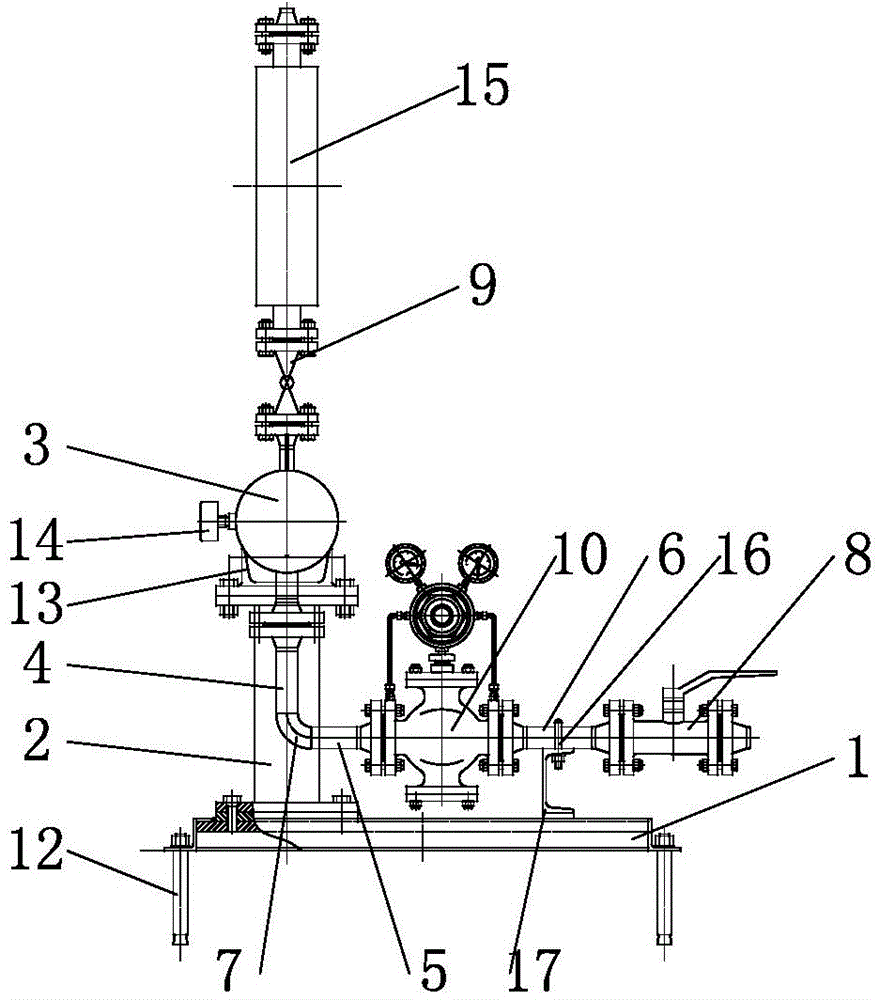

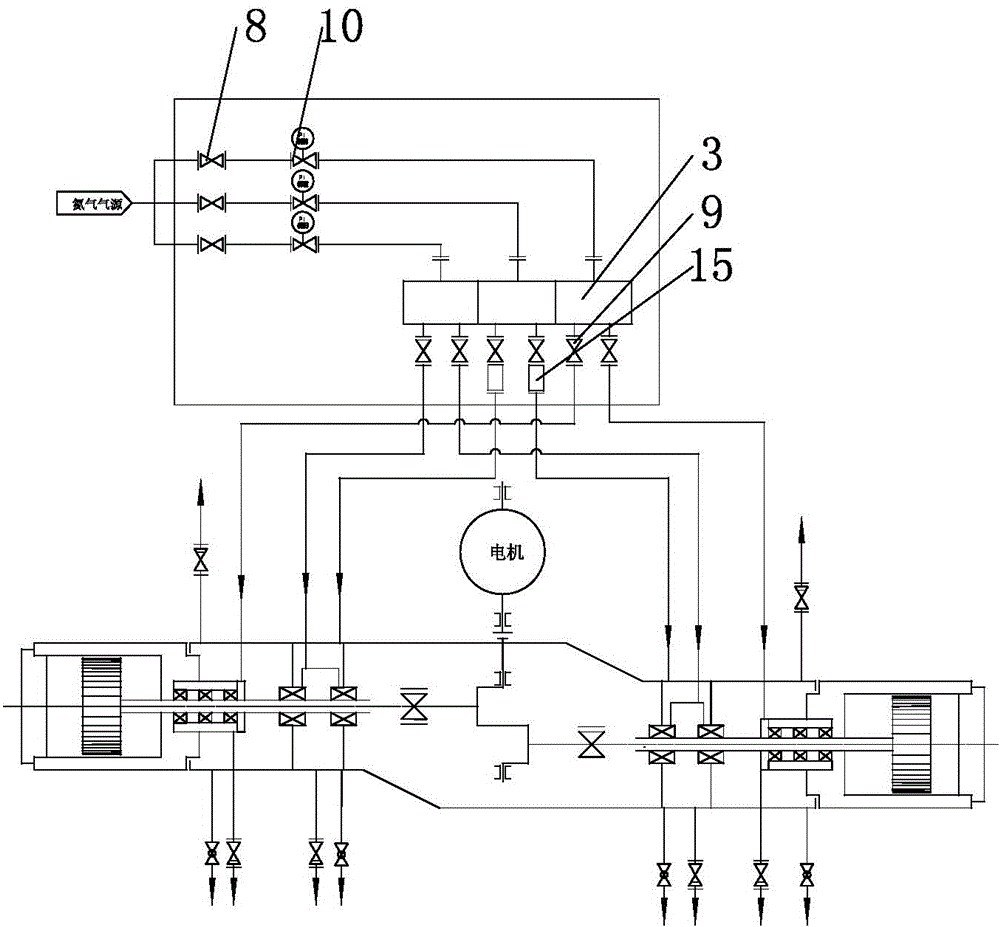

[0016] combine figure 1 and figure 2 As shown, the reciprocating piston compressor filling leakage protection gas distribution station of the present invention includes a chassis 1, a pillar 2, and a gas collection tank 3, and also includes a first seamless steel pipe 4, a second seamless steel pipe 5, and a third seamless steel pipe with the same number. Seam steel pipe 6, long radius elbow 7, first ball valve 8, second ball valve 9, pressure reducing valve 10 and support frame 17, chassis 1 is fixedly installed on the ground through expansion bolts 12, and the rear end of chassis 1 is provided with two pillars 2. The lower end of each pillar 2 is connected to the chassis 1 by bolts, and the upper end of each pillar 2 is provided with an air collecting tank tray 13, and the air collecting tank 3 is arranged on the tray 13, and the inside of the air collecting tank 3 is divided into left , middle and right areas, each area of the gas collection tank 3 is connected with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com