Y-type three-track sliding integrated machine

An all-in-one machine and sliding technology, which is applied to steering mechanisms, roads, road repairs, etc., can solve problems such as limiting work efficiency, places that are difficult to maintain, and inconvenient maintenance and repair, so as to achieve improved work efficiency, low use cost, The effect of flexible and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

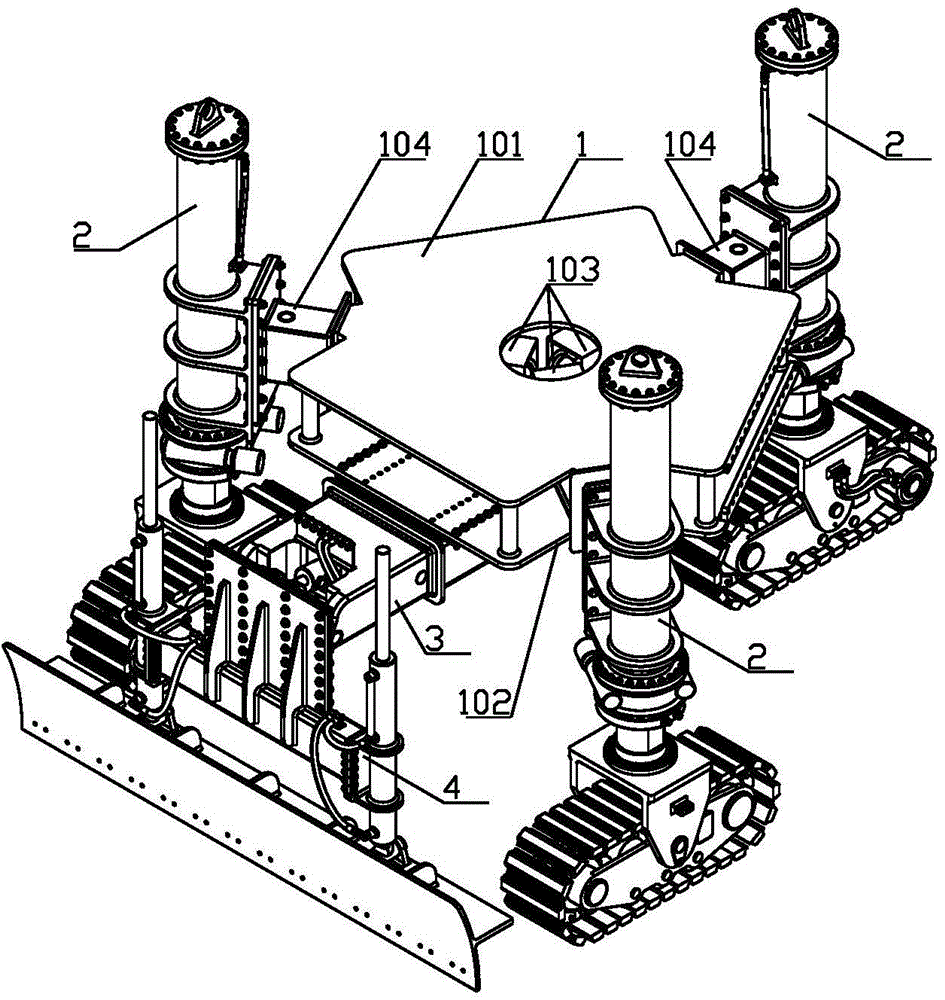

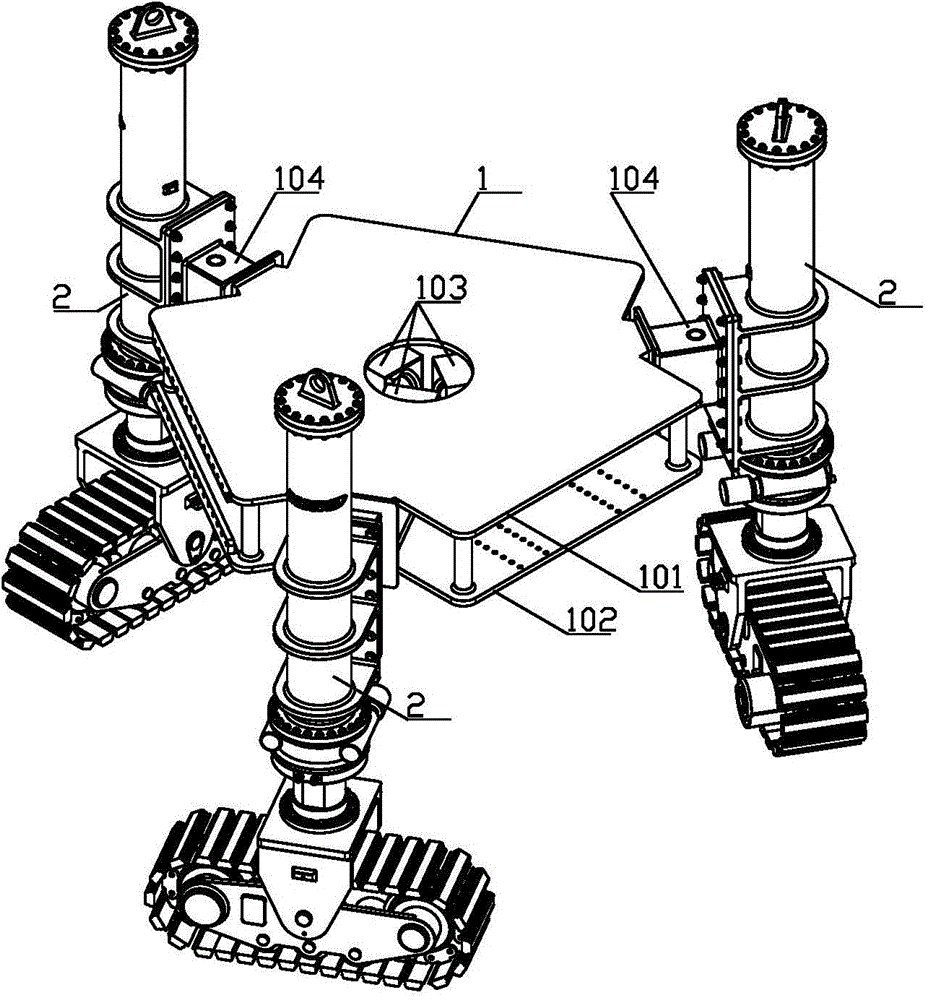

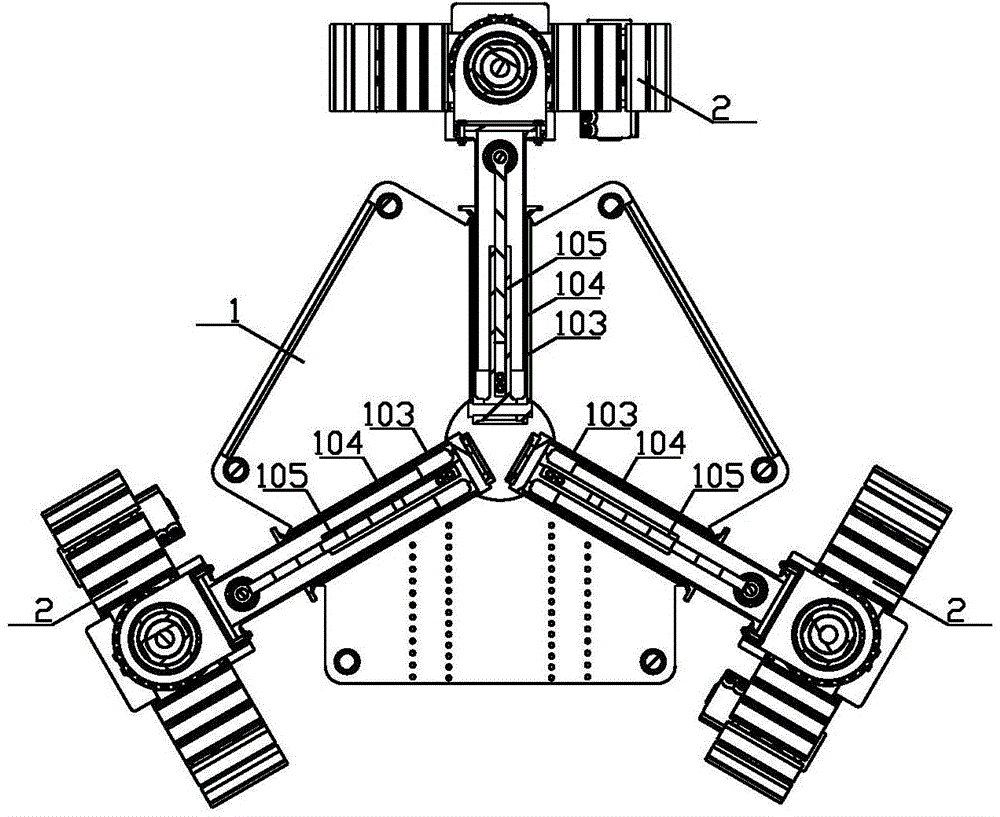

[0038] Embodiment 1: Y-type three-track sliding integrated machine, such as figure 1 As shown, it includes a Y-shaped telescopic chassis 1 and a crawler-type lifting steering device 2, such as figure 2 and image 3 As shown, the Y-shaped telescopic chassis includes an upper base plate 101, a lower base plate 102, three hollow main beams 103, and three hollow telescopic beams 104; The beams 103 are arranged in a Y shape, and the three main beams 103 are evenly arranged between the upper base plate 101 and the lower base plate 102, and the angle between any two adjacent main beams 103 is 120°; A telescopic beam 104 is connected; one end of the telescopic beam 104 is slidably inserted into the inner chamber of the main beam 103, and a telescopic beam oil cylinder 105 is arranged in each telescopic beam 104, and the top end of the piston rod of the telescopic beam oil cylinder 105 passes through the telescopic beam 104. The pin shaft is fixedly connected, and the cylinder body ...

Embodiment 2

[0039] Embodiment 2: as Figure 9 As shown, the Y-type three-track sliding integrated machine includes a Y-shaped telescopic chassis 1 and a crawler-type lifting and steering device 2, and a horizontal telescopic arm 3 is provided at the bottom of the lower floor 102 between adjacent main beams 103. The structure is the same as in Example 1, the difference is that, as Figure 10 As shown, two lifting cylinders 306 are vertically and parallelly arranged on the fixing plate 303. The piston rods of the two lifting cylinders protrude in the same direction, and the piston rods of the lifting cylinders 306 protrude downward. Suspended slip form holder 307, such as Figure 11 As shown, the lower suspended sliding form fixture 307 includes a bottom plate 308, two side plates 309, two movable splints A310, a splint limiter A311, a fixer oil cylinder A312, and a sliding form connecting plate A313; on the bottom plate 308, there are The splint limit chute 314 is provided with a connect...

Embodiment 3

[0040] Embodiment 3: as Figure 22 As shown, the Y-type three-crawler sliding integrated machine includes a Y-type telescopic chassis 1 and a crawler-type lifting and steering device 2, such as figure 2 and image 3 As shown, the Y-shaped telescopic chassis includes an upper base plate 101, a lower base plate 102, three hollow main beams 103, and three hollow telescopic beams 104; The beams 103 are arranged in a Y shape, and the three main beams 103 are evenly arranged between the upper base plate 101 and the lower base plate 102, and the angle between any two adjacent main beams 103 is 120°; A telescopic beam 104 is connected; one end of the telescopic beam 104 is slidably inserted into the inner chamber of the main beam 103, and a telescopic beam oil cylinder 105 is arranged in each telescopic beam 104, and the top end of the piston rod of the telescopic beam oil cylinder 105 passes through the telescopic beam 104. The pin shaft is fixedly connected, and the cylinder body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com