LED lamp tube

A technology of LED lamps and LED light sources, applied in the field of LED lamps, can solve problems such as inaccessible maintenance, affecting luminous effect, complex structure, etc., and achieves the effects of simple and convenient maintenance, flexible installation and disassembly, and flexible installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

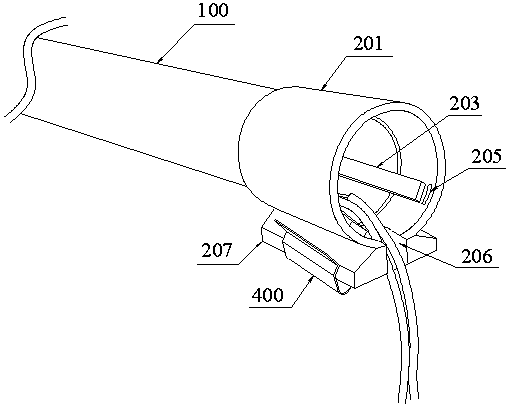

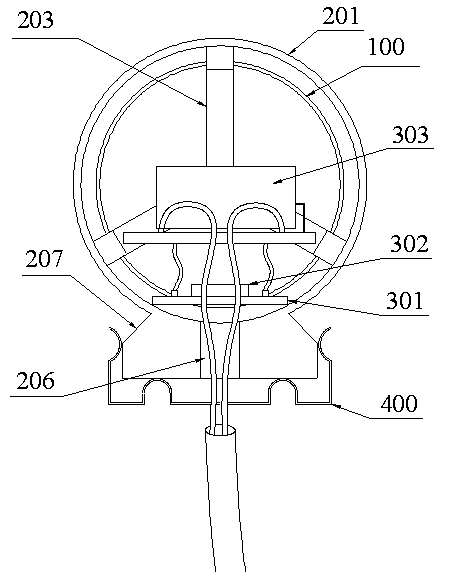

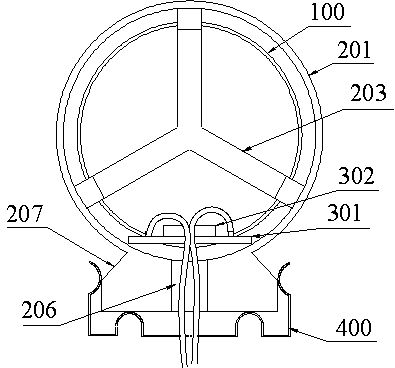

[0024] refer to Figure 1 to Figure 6 , an embodiment of an LED lamp tube of the present invention is proposed, including a tube body 100 , end cap structures disposed at both ends of the tube body 100 , and an LED light source assembly disposed in the tube body 100 .

[0025] The end cap structure includes an end cap tube 201 connected and fixed at both ends of the tube body 100 , and a cover body 202 that fits in shape with the end cap tube 201 and is engaged and fixed on the outer surface of the end cap tube 201 . The setting of the cover body 202 facilitates inspection and maintenance of the driving device 303 and the circuit.

[0026] The LED light source assembly includes a substrate 301 fixed inside the tube body 100 , an LED lamp bead 302 arranged on the substrate 301 , and a driving device 303 electrically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com