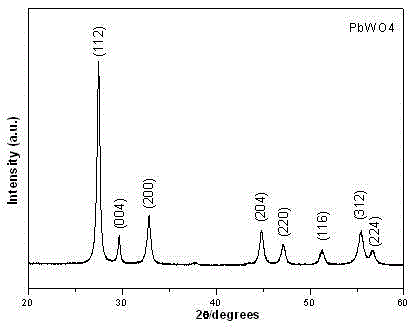

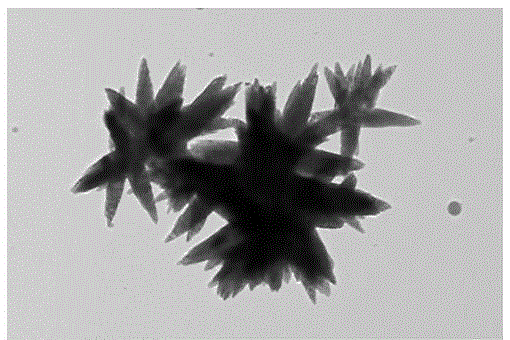

A kind of preparation method of spindle-shaped lead tungstate crystal

A lead tungstate spindle and crystal technology is applied in the field of preparation of lead tungstate spindle-shaped crystals, which can solve the problems of polluted environment and complicated operation, and achieve the effects of large specific surface area, simple operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1, dissolving disodium edetate in deionized water to form an aqueous solution of disodium edetate, adjusting the concentration of edetate in the solution to 0.04mol / L;

[0024] Step 2, dissolve lead nitrate in deionized water to form lead nitrate aqueous solution, adjust the Pb in the solution 2+ The ion concentration is 0.04mol / L;

[0025] Step 3, mixing the disodium edetate aqueous solution prepared in step 1 with the lead nitrate aqueous solution prepared in step 2, the mixing molar ratio of disodium edetate and lead nitrate is 1:1 to obtain ethylenediaminetetraacetic acid Lead amine tetraacetate precipitation solution, let stand for 0.5 hour;

[0026] Step 4. Dissolve sodium tungstate in deionized water to form an aqueous solution of sodium tungstate, and adjust the WO in the solution 4 2- The ion concentration is 0.04mol / L;

[0027] Step five, the aqueous sodium tungstate solution prepared in step four is mixed with the lead edetate precipitation solution ...

Embodiment 2

[0030] Step 1, dissolving disodium edetate in deionized water to form an aqueous solution of disodium edetate, adjusting the concentration of edetate in the solution to 1.1 mol / L;

[0031] Step 2, dissolve lead nitrate in deionized water to form lead nitrate aqueous solution, adjust the Pb in the solution 2+ The ion concentration is 1.1mol / L;

[0032] Step 3, mixing the disodium edetate aqueous solution prepared in step 1 with the lead nitrate aqueous solution prepared in step 2, the mixing molar ratio of disodium edetate and lead nitrate is 1:1 to obtain ethylenediaminetetraacetic acid Lead amine tetraacetate precipitation solution, let stand for 40 minutes;

[0033] Step 4. Dissolve sodium tungstate in deionized water to form an aqueous solution of sodium tungstate, and adjust the WO in the solution 4 2- The ion concentration is 1.1mol / L;

[0034] Step five, the aqueous sodium tungstate solution prepared in step four is mixed with the lead edetate precipitation solution ...

Embodiment 3

[0036] Step 1, dissolving disodium edetate in deionized water to form an aqueous solution of disodium edetate, adjusting the concentration of edetate in the solution to 2.0 mol / L;

[0037] Step 2, dissolve lead nitrate in deionized water to form lead nitrate aqueous solution, adjust the Pb in the solution 2+ The ion concentration is 2.0mol / L;

[0038] Step 3, mixing the disodium edetate aqueous solution prepared in step 1 with the lead nitrate aqueous solution prepared in step 2, the mixing molar ratio of disodium edetate and lead nitrate is 1:1 to obtain ethylenediaminetetraacetic acid Lead amine tetraacetate precipitation solution, leave standstill for 50 minutes;

[0039] Step 4. Dissolve sodium tungstate in deionized water to form an aqueous solution of sodium tungstate, and adjust the WO in the solution 4 2- The ion concentration is 2.0mol / L;

[0040] Step five, the aqueous sodium tungstate solution prepared in step four is mixed with the lead edetate precipitation so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com