Method for reducing content of iron ions in orthophosphorous acid

A technology of iron ions and phosphorous acid, applied in the chemical field, can solve the problems of difficult treatment of regenerated liquid, high production cost, large environmental pollution, etc., and achieve the effects of simple operation, scientific principle and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

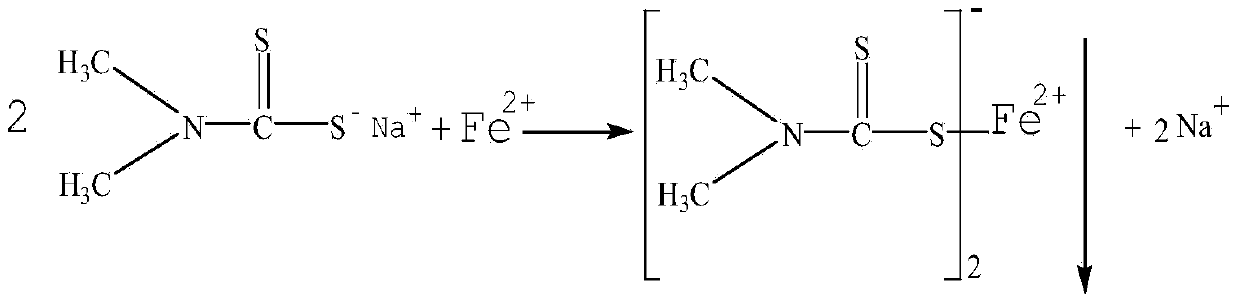

Method used

Image

Examples

Embodiment 1

[0022] 1000kg of phosphorous acid mother liquor with an iron ion content of 200ppm is dropped into the reactor, and the stirring is started. In the jacket of the reactor, icy brine is introduced to control the material temperature in the kettle to be 20° C., 2 kg of activated carbon is added, and then sodium formamate solution is slowly added dropwise ( 40% mass percent concentration) 3kg, the control reaction temperature is 20~22 ℃, dropwise completes heat preservation reaction for 30 minutes, then pressure filtration, the filtrate is transferred to the concentrated kettle and distilled under reduced pressure to 120 ℃ under the vacuum degree of -0.095MPa, Then transfer to the crystallization kettle for cooling and crystallization, and finally transfer to the centrifugal kettle to obtain 815kg of phosphorous acid finished product. The detected phosphorous acid content is 99.24%, and the iron ion content is 16ppm.

Embodiment 2

[0024] 1000kg of phosphorous acid mother liquor with an iron ion content of 800ppm is dropped into the reactor, and the stirring is started. In the jacket of the reactor, icy brine is introduced to control the temperature of the material in the kettle to be 10° C., 2 kg of activated carbon is added, and then sodium formamate solution is slowly added dropwise ( 40% mass percentage concentration) 8kg, the control reaction temperature is 10~12 ℃, dropwise completes heat preservation reaction for 30 minutes, then pressure filtration, the filtrate is transferred to the concentration kettle and distilled under reduced pressure to 120 ℃ under -0.095MPa vacuum degree, Then transfer to the crystallization kettle for cooling and crystallization, and finally transfer to the centrifugal kettle to obtain 800kg of phosphorous acid finished product. The detected phosphorous acid content is 98.58%, and the iron ion content is 42ppm.

Embodiment 3

[0026] 500kg of phosphorous acid mother liquor with an iron ion content of 300ppm is dropped into the reactor, and the stirring is started. In the jacket of the reactor, icy brine is introduced to control the temperature of the material in the kettle to be 5° C., 2 kg of activated carbon is added, and then sodium formamate solution is slowly added dropwise ( 40% mass percentage concentration) 7kg, control the reaction temperature to be 5~7 ℃, dropwise complete the insulation reaction for 30 minutes, then press filter, transfer the filtrate to the concentration kettle and distill under reduced pressure to 120 ℃ under the vacuum degree of -0.095MPa, Then transfer to the crystallization kettle for cooling and crystallization, and finally transfer to the centrifugal kettle to obtain 435kg of phosphorous acid finished product. The detected phosphorous acid content is 99.10%, and the iron ion content is 21ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com