Apparatus and methods for conversion of silicon tetrachloride to trichlorosilane

A chlorosilane and converter technology, applied in the field of hydrogenation devices, can solve the problems that the system is not widely used and not commercially available

Active Publication Date: 2014-08-13

ADVANCED MATERIAL SOLUTIONS LLC

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, such purpose-built systems are not widely used nor are they commercially available

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0082] Fluid flow and heat transfer within converter 110 are modeled using numerical modeling techniques. The computational fluid dynamics (CFD) software used for the simulation was developed by Ans y ANSYS FLUENT provided by s company. The input parameters and results of the simulations are provided in Table 1 below.

[0083]

[0084]

[0085] Table 1 The input parameters and results of CFD simulation.

[0086] equivalent

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

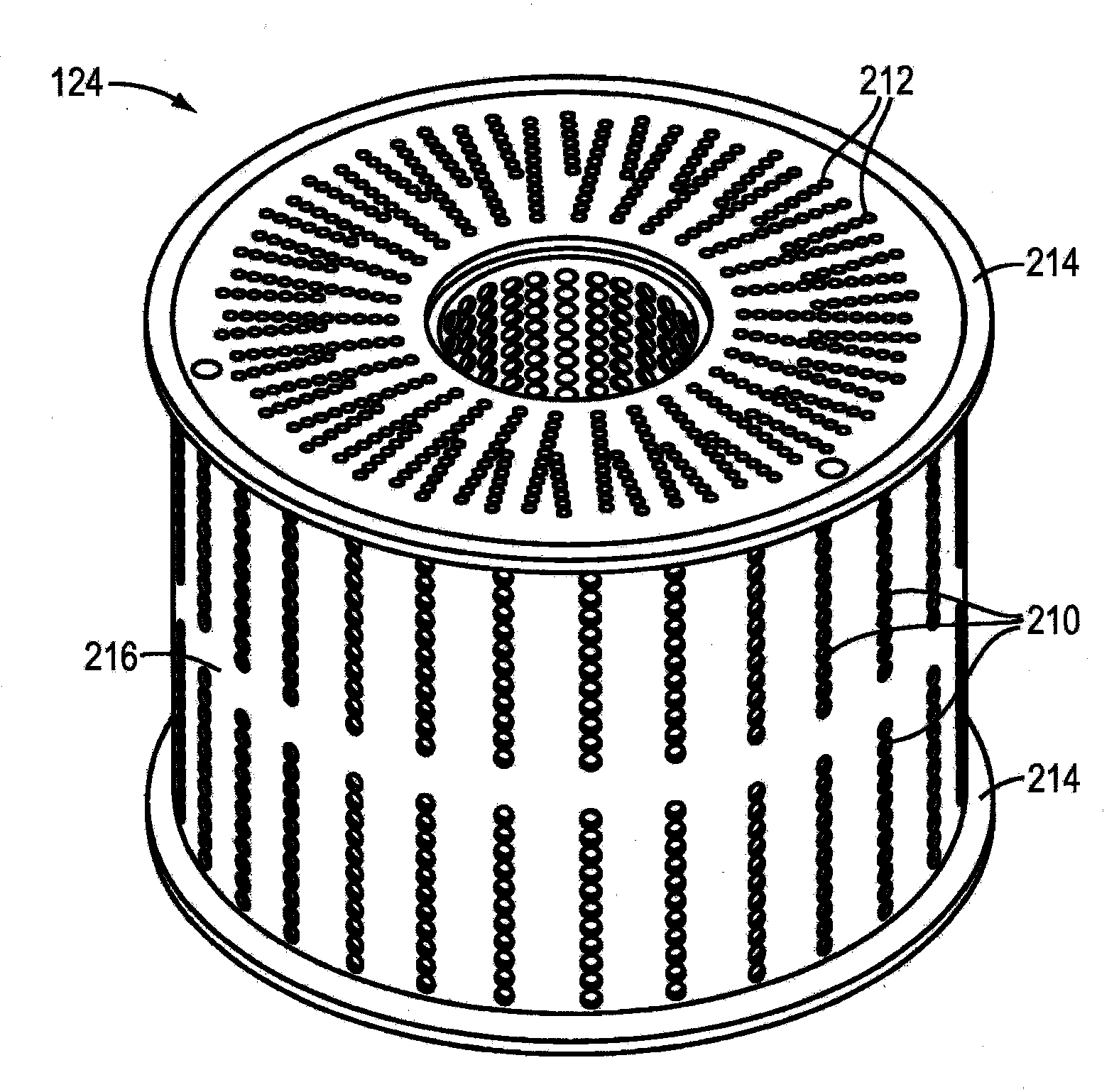

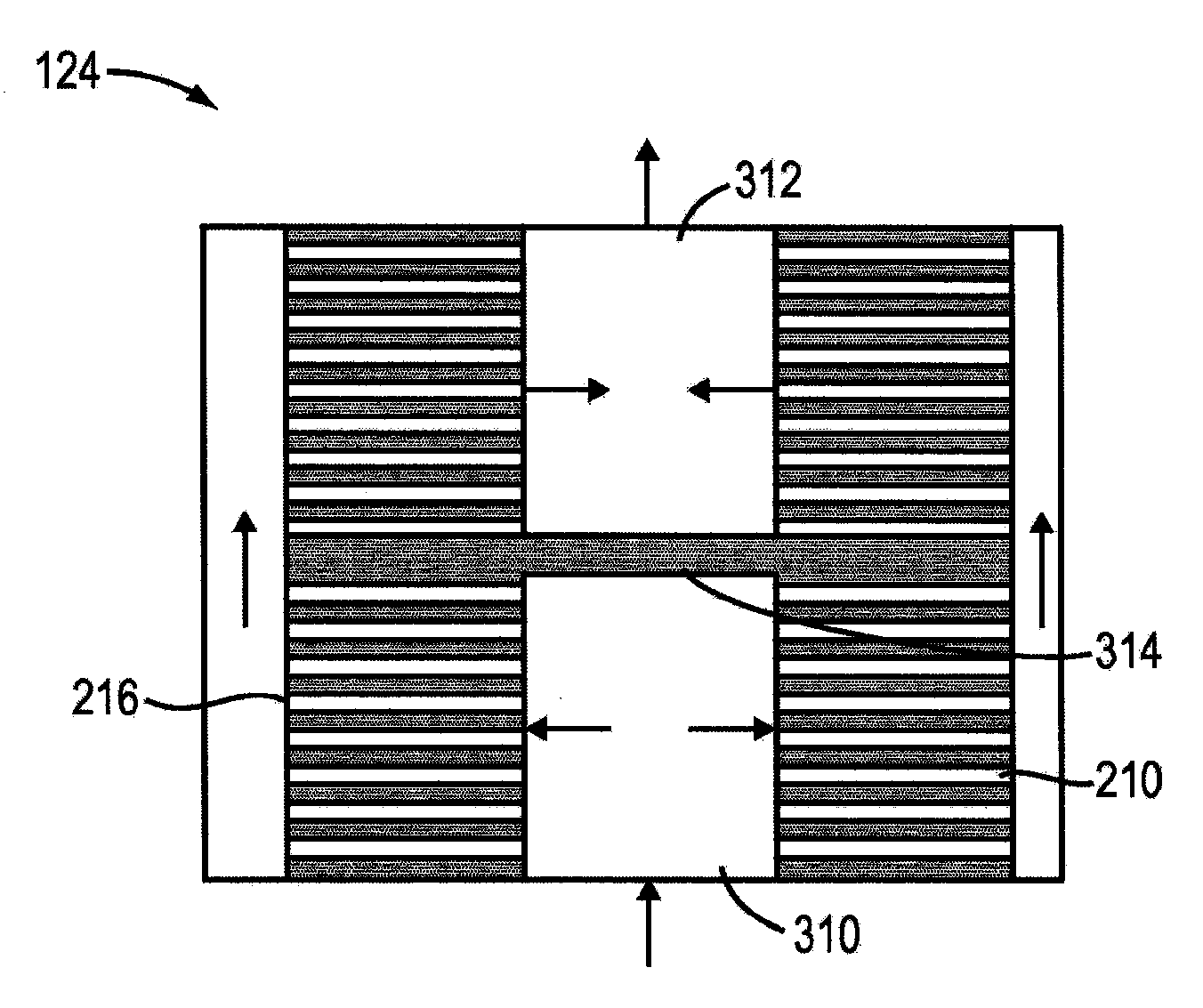

The invention relates to apparatus and associated methods for conversion of silicon tetrachloride (STC) to trichlorosilane (TCS). The converter features a relatively thin annular heating zone surrounding a reaction chamber. Within the annular heating zone is a heating element that has an annular conformation about the reaction chamber. The design allows high convective heat transfer, which facilitates the use of lower heating element surface temperatures, prolonging the life of the equipment, reducing capital cost by allowing use of a smaller reactor, and greatly improving heating efficiency. A heat exchanger with a plurality of heat exchanger blocks provides further efficiency.

Description

technical field [0001] The present invention generally relates to apparatus and methods for the hydrogenation of chlorosilanes. More particularly, in certain embodiments, the present invention relates to apparatus and methods for converting silicon tetrachloride (STC) to trichlorosilane (TCS). [0002] This patent application claims the benefit of U.S. Provisional Patent Application No. 61 / 499,451 and U.S. Provisional Patent Application No. 61 / 499,461, both filed June 21, 2011, the disclosures of which are hereby incorporated by reference in It is incorporated herein by reference in its entirety. Background technique [0003] Chemical vapor deposition (CVD) reactors are used to produce polycrystalline silicon (polysilicon), the key raw material used in silicon-based solar wafers and cells. Polysilicon is also used to make semiconductor wafers for microelectronics applications. The most widely used method for producing polysilicon is the Siemens reactor process, which has ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J19/00C01B33/107

CPCB01J19/0013B01J2219/00094B01J2219/0002B01J2219/00085B01J19/0053B01J2219/00159C01B33/1071F28F7/02Y02P20/10B01J2219/00135B01J19/24B01J12/00B01J2219/00103B01J12/005

Inventor S·法伦布鲁克B·黑兹尔坦A·施魏恩S·斯金纳

Owner ADVANCED MATERIAL SOLUTIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com