Metal interconnect structure and method of manufacturing the same

A technology of metal interconnection structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of high mechanical strength requirements of CNT through holes, achieve guaranteed density, facilitate high-density growth, Improve the effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object and features of the present invention more obvious and easy to understand, the specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. However, the present invention can be realized in different forms, and should not be considered as being limited to the described embodiments .

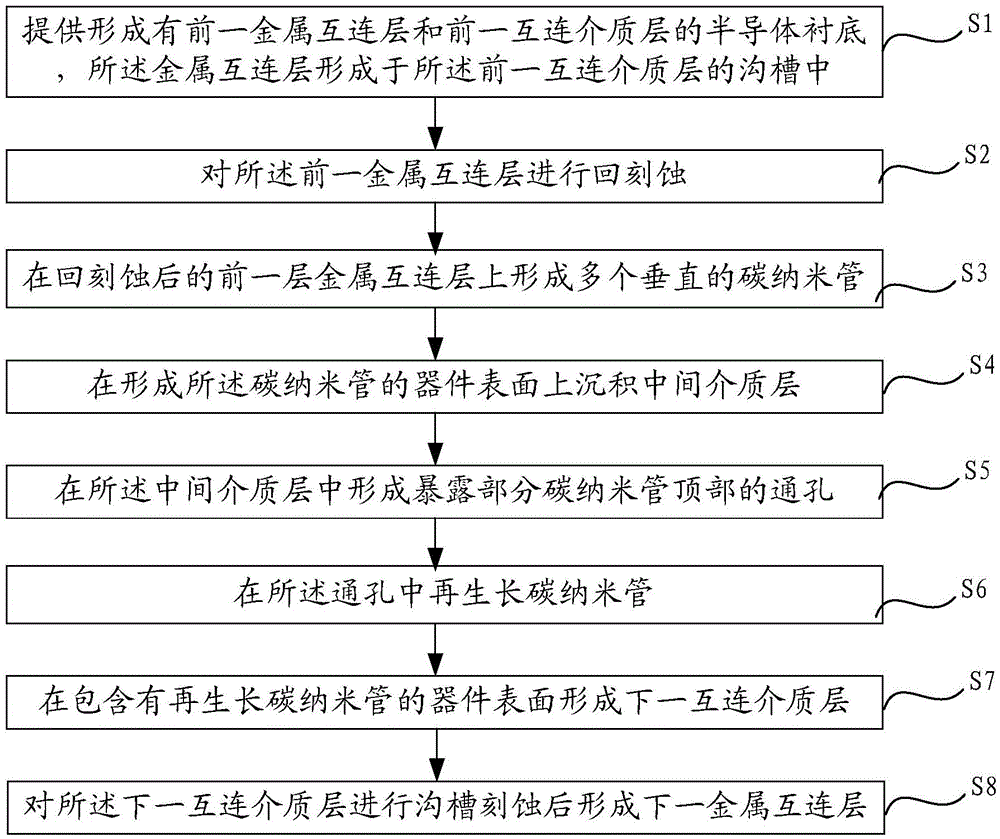

[0033] Please refer to figure 2 , the present invention proposes a method for manufacturing a metal interconnection structure, comprising the following steps:

[0034] S1, providing a semiconductor substrate formed with a previous metal interconnect layer and a previous interconnect dielectric layer, the metal interconnect layer is formed in the trench of the previous interconnect dielectric layer;

[0035] S2, etching back the previous metal interconnection layer;

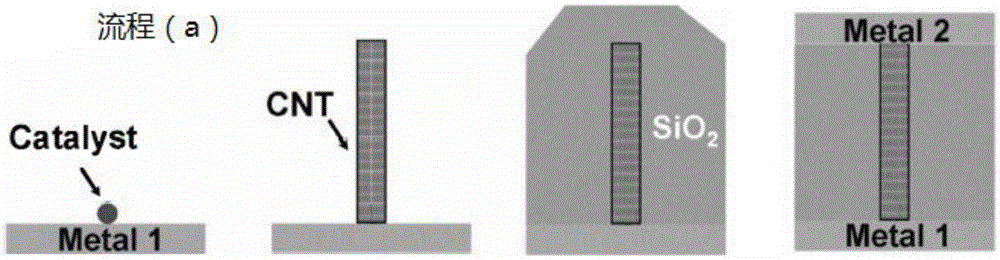

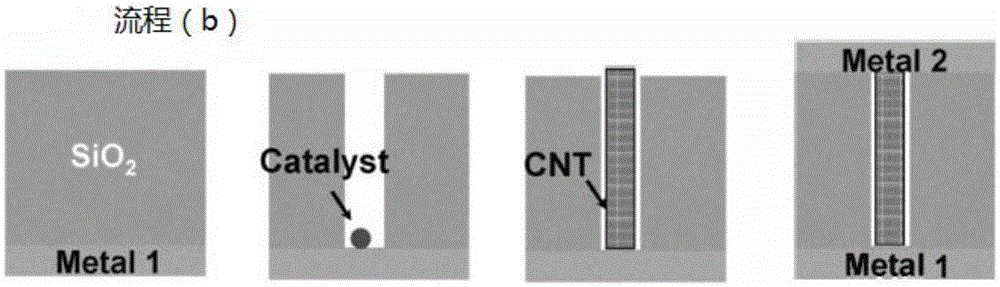

[0036] S3, forming a plurality of vertical carbon nanotubes on the previous metal interconnection layer after etching back;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com