Segmented ceramic kiln fuel gas and air linkage control system

A linkage control system and ceramic kiln technology, applied in the direction of combustion control, combustion method, fuel supply adjustment, etc., can solve the problem that the amount of combustion-supporting air cannot be synchronized or followed, the effect of pressure and temperature conversion is not obvious, and cannot be adjusted at the same time The size of gas volume and other issues, to achieve the effect of simple structure, small quantity, enhanced convection heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

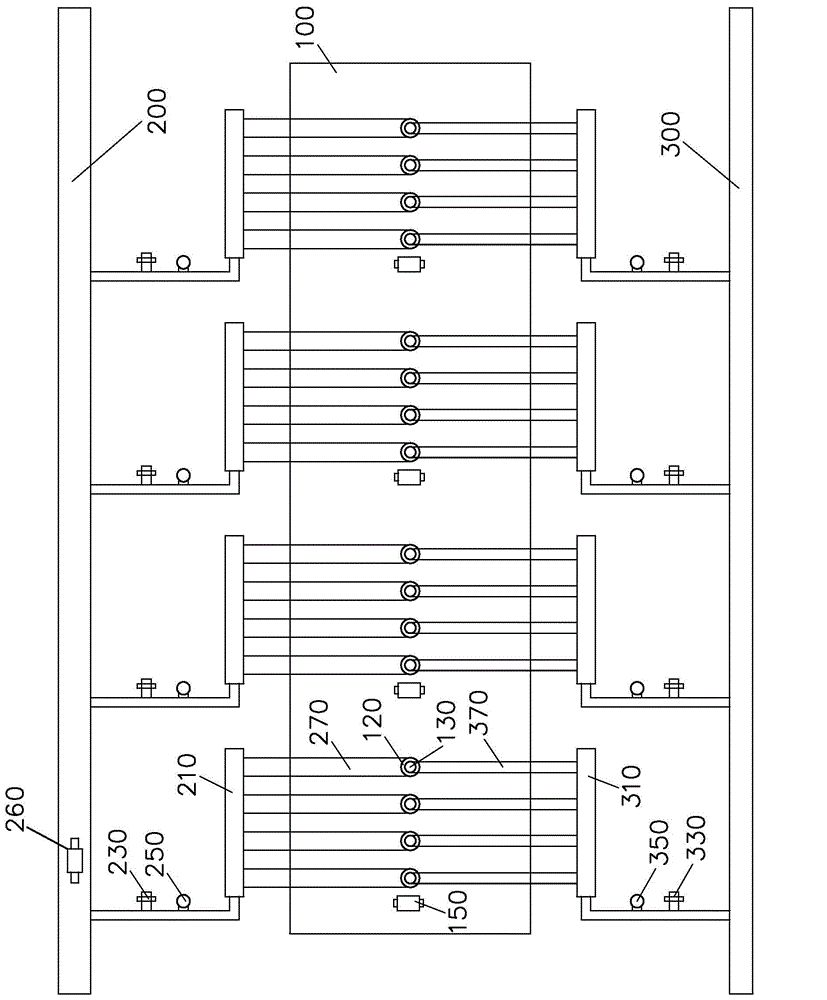

[0030] Please refer to figure 1 As a non-limiting example embodiment, the segmented ceramic kiln gas and air linkage control system of the present invention includes: a kiln body 100, an air main pipe 200, a gas main pipe 300, and four control zones (not labeled).

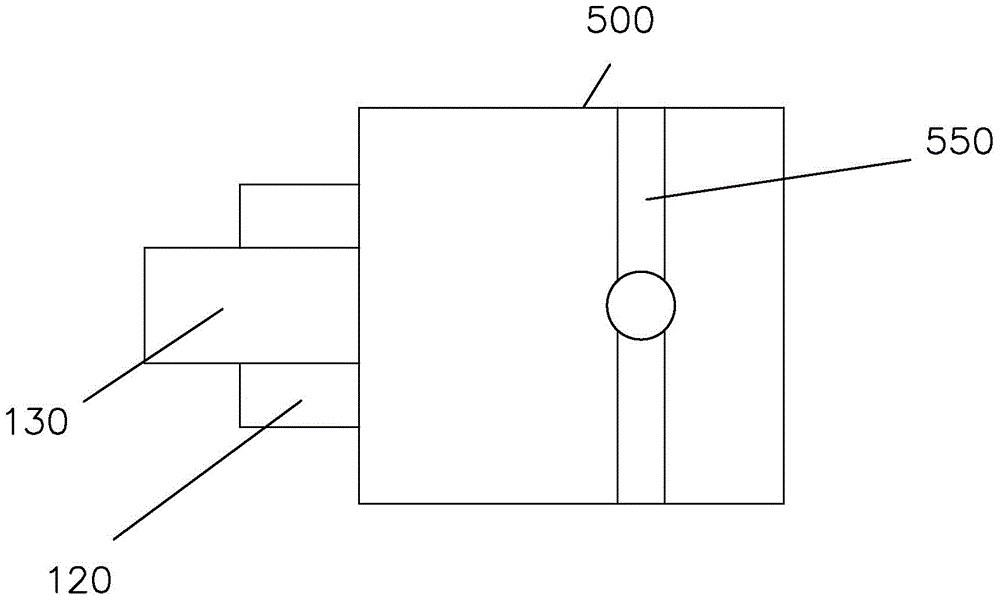

[0031] The kiln body 100 is provided with sixteen air inlets 120 and sixteen gas inlets 130. A first thermocouple 260 is provided in the air manifold 200.

[0032] Each control zone includes: an air branch pipe 210; an air electric valve 230 and an air flow meter 250 arranged on the connecting pipeline between the air branch pipe 210 and the air main pipe 200; and four connected between the air branch pipe 210 and the air inlet 120 Air input pipe 270. A second thermocouple 150 is provided to obtain the zone temperature data in the kiln body

[0033] Each control zone also includes: a gas branch pipe 310; a gas electric valve 330 and a gas flow meter 350 arranged on the connecting pipeline between the gas branch pipe 310...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com