Method for recovering broken ore body by access sub-step roof popping

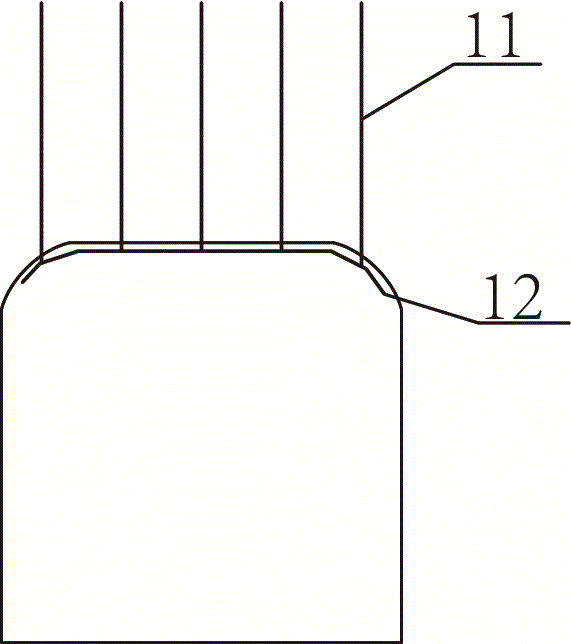

An approach and ore body technology, which is used in the mining and support of broken ore bodies near the main ore-controlling faults, and in the field of mine broken ore body approach mining. and other problems, so as to solve the technical problems of support, improve the overall support force, and enhance the effect of three-dimensional prestressing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

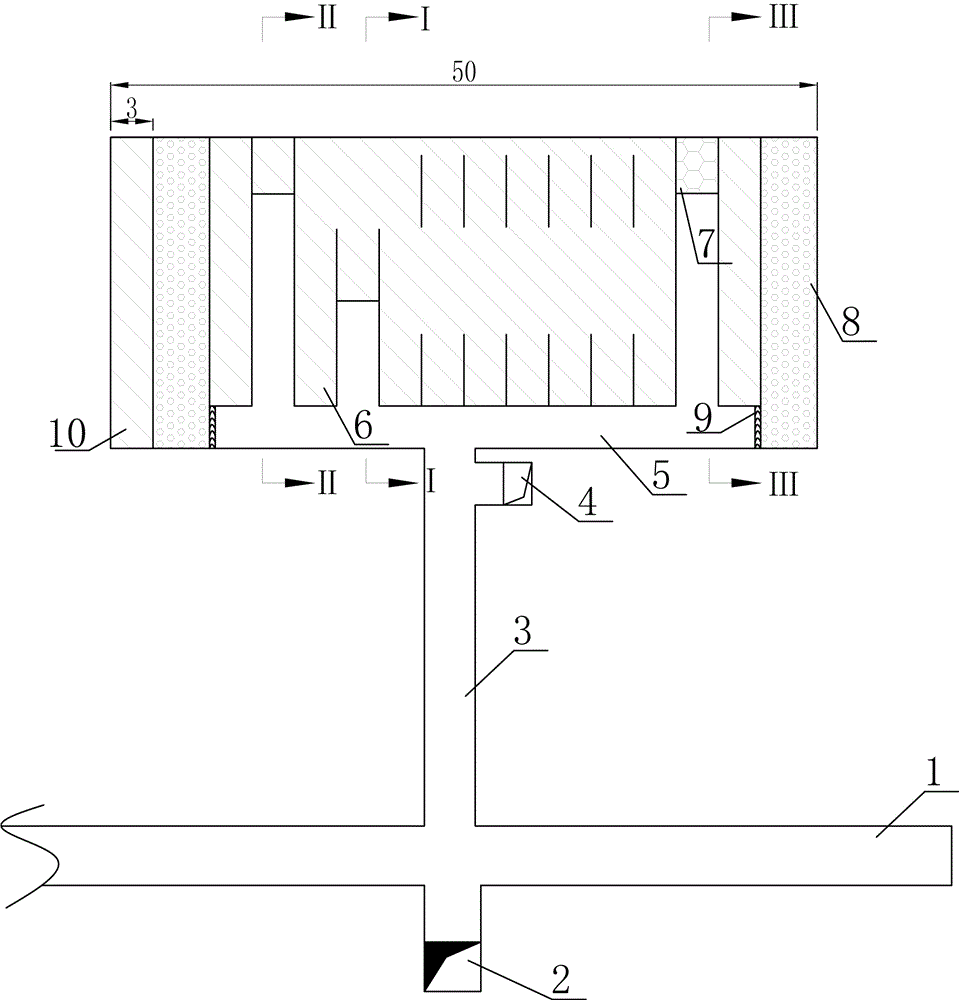

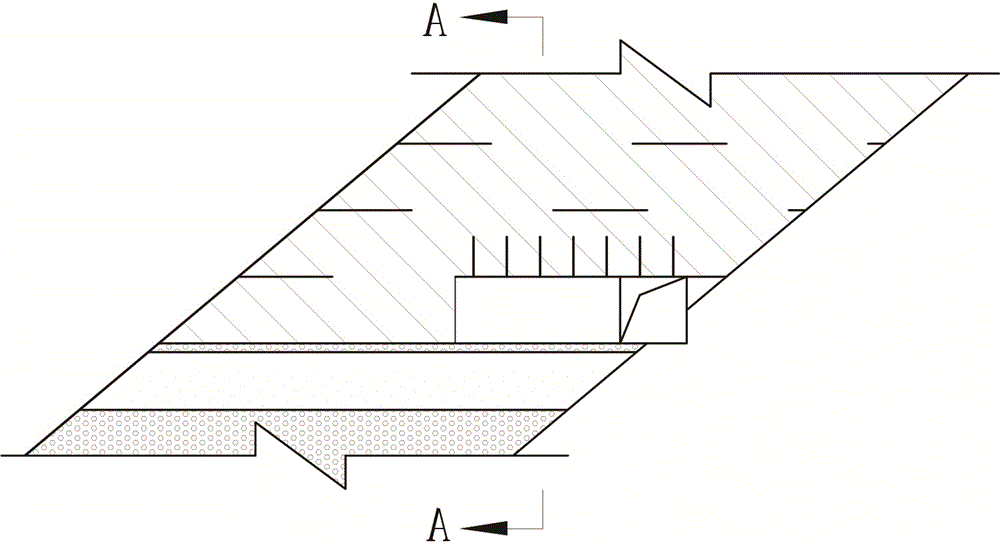

[0026] 1. The approach stope structure is arranged in a strip-shaped approach according to the vertical direction. The length of the stope direction is 50m, and the width of the middle column 10 is 3m.

[0027] 2. After arriving at the stope from the construction stope connecting road 3 of the section transportation level entry 1, the return air patio 4 and the layered cutting entry 5 arranged along the direction of the footwall are successively constructed;

[0028] 3. According to the layered design, the strip-shaped approach 6 is mined at intervals: the strip-shaped approach 6 has a specification of 3-4m×3m (width×height); the strip-shaped approach 6 can work on multiple working faces at the same time, and the depth of the blast hole is 2.5m. The circular footage is 2m; the ore is unloaded to the sectional slide shaft 2 by ST-2D diesel scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com