Three-phase metering device for medium and small liquid volume and large volume oil wells

A metering device and gas volume technology, applied in the direction of measurement, wellbore/well components, production fluid, etc., can solve the problems of inability to measure water content, unsatisfactory use of oil wells, online measurement, etc., to reduce equipment failure points, The effect of small footprint and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

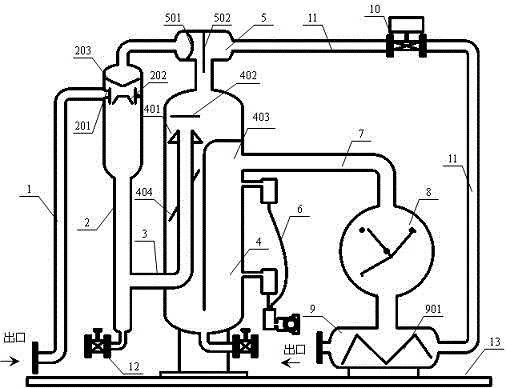

[0031] Such as figure 1 As shown, a three-phase metering device for oil wells with small and medium liquid volume and large volume, including gas-liquid cyclone separator 2, flow stabilizer 4, gas circuit buffer tank 5, tipping bucket flowmeter 8 (application number: 201110321654.0), gas flow rate Gauge 10, gas-liquid combining tank 9, differential pressure transmitter 6, gas main pipe 11, medium inlet pipe 1, overflow pipe 3, liquid pipe 7 and bottom plate 13. The entire device sits on a base plate 13 .

[0032] The main function of the gas-liquid cyclone separator 2 is to complete the gas-liquid cyclone separation and baffle separation of incoming liquid from the oil well. The shell of the gas-liquid cyclone separator 2 is a vertical cylinder, the side of the shell is connected to the medium inlet pipe 1, the bottom is connected to the overflow pipe 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com