Well casing recovery method

A technology of drilling casing and recovery method, which is applied in earthwork drilling, wellbore/well components, coal gasification, etc., can solve the problems of recovery and reuse of few drilling casings, and achieve the effect of effective recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

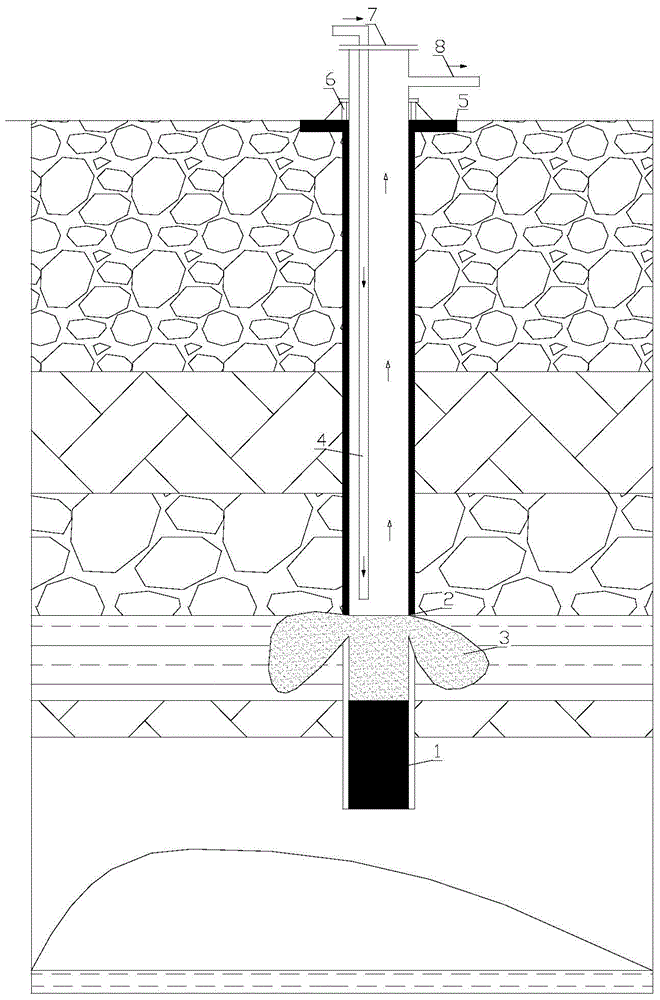

[0031] figure 1 It is a structural schematic diagram of the drilling provided by the present invention, and the following is combined with the attached figure 1 The technical solutions of the present invention will be further described through specific embodiments.

[0032] The drilling casing recovery method disclosed in the present invention comprises the following steps:

[0033] S1. A predetermined amount of cementitious material is injected into the well to form a fixed isolation layer 1 in the well.

[0034] Specifically, firstly, the position where the isolation layer 1 is arranged in the drilling casing 2 should be determined according to the hydrogeological conditions of the location where the drilling is located. The drilling casing 2 is used to support the steel pipe of the drilling well wall, so as to ensure the normal operation of the whole drilling during the drilling process and after the completion of the well. As a preferred solution, generally, the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com