A group control tour type automatic doffing method

An automatic doffing and touring technology, applied in textiles and papermaking, etc., can solve the problems of laborious operation, high labor intensity, improper operation, etc., and achieve the effect of avoiding misoperation, saving failure time, and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be described in detail below.

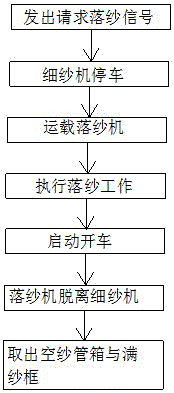

[0031] Such as figure 1 As shown, a group control tour type automatic doffing method of the present invention comprises the following steps:

[0032] Step 1: Send a doffing request signal: the spinning frame sends a doffing request signal to the automatic guided transport vehicle equipped with the doffer. The request doffing signal includes spinning frame number information, the waiting terminal position information of the automatic guided transport vehicle and the request doffing information. Wherein, the requested doffing information includes the doffing object, the doffing location, and the doffing time.

[0033] In the first step, the same spinning frame sends a doffing request signal to two automatic guided transport vehicles at the same time; advance, and the two automatic guided transport vehicles stay at the waiting end position next to the spinning frame, and the two automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com