Double tuyere buffer type converter secondary flue gas capture device

A technology of secondary flue gas and double tuyere, which is applied in the manufacture of converters, etc., can solve the problems of increased initial equipment investment, increased operating costs, and failure to meet energy saving and emission reduction, and achieve the effect of simple structure and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

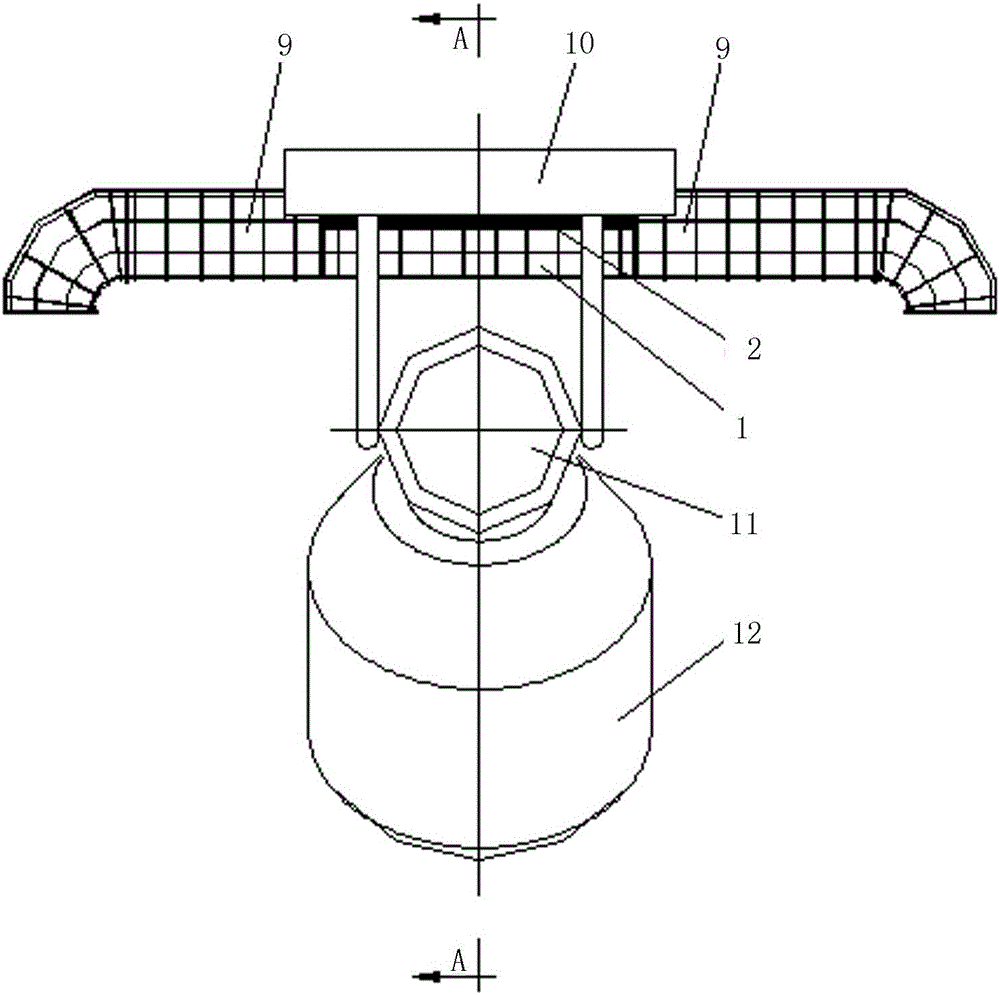

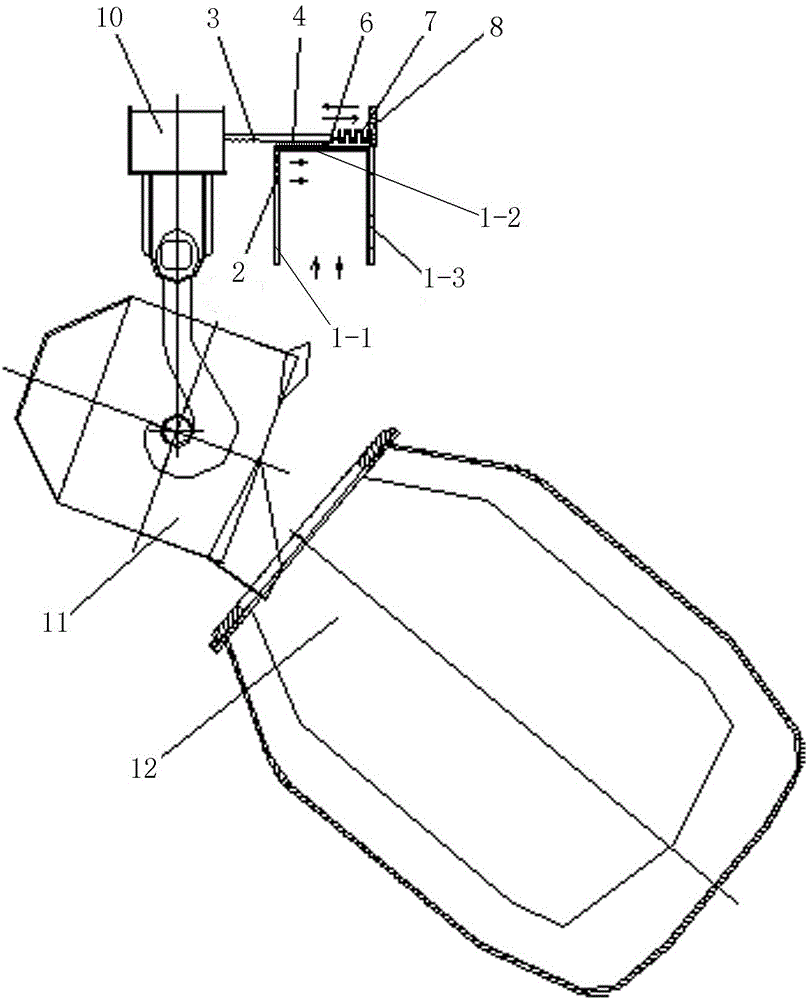

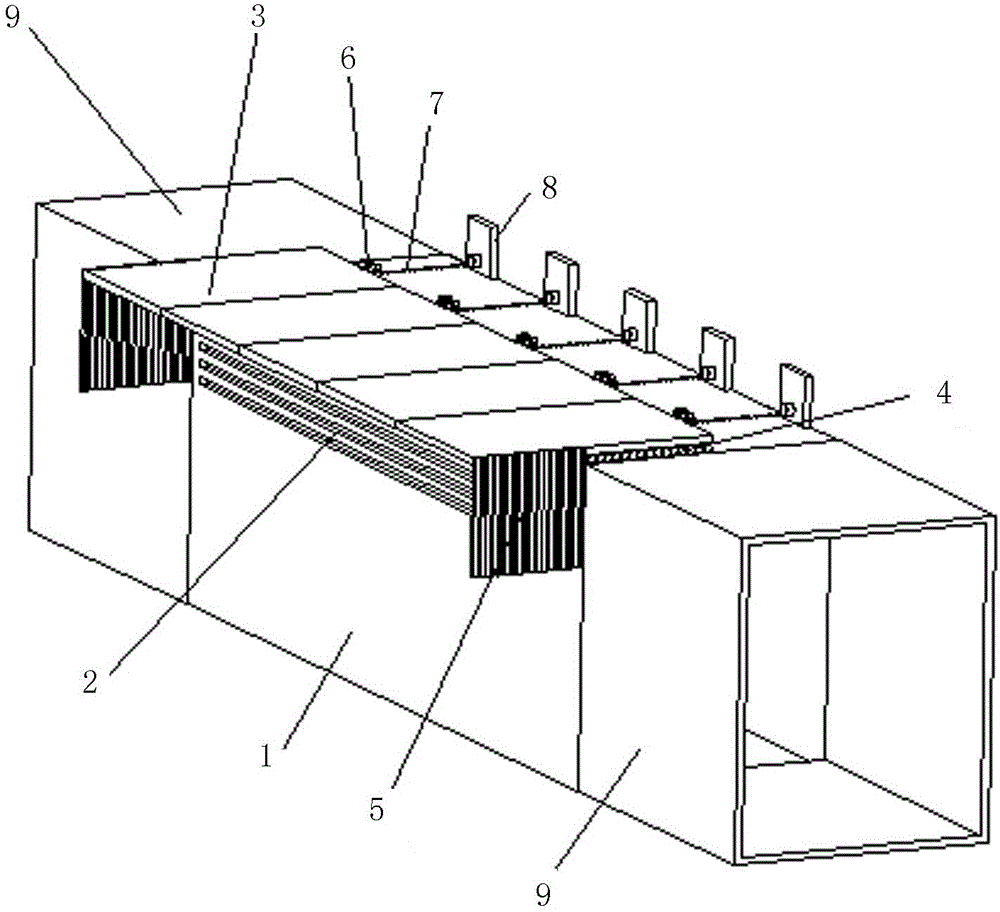

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] see Figure 1-Figure 3 , a double-tuyere buffer type converter secondary flue gas capture device, which includes a capture cover 1 arranged on a converter 12, and the capture cover 1 communicates with an external dust removal pipeline through an exhaust pipe 9; the capture The cover 1 includes a front panel 1-1, a top panel 1-2 and a rear panel 1-3, and the front panel 1-1, the top panel 1-2 and the rear panel 1-3 are sequentially connected to form a hollow groove with an opening below Body, and both ends of the hollow tank body are connected with the exhaust pipe 9; the top plate 1-2 is provided with a shielding top plate 3, and the shielding top plate 3 extends out of the top plate 1-2; the shielding top plate 3 One end of the spring 7 is connected through the connecting device 6, and the other end of the spring 7 is connected with the fixing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com