Modularized assembly type roof building integrated photovoltaic (BIPV) system and installation method thereof

A prefabricated and modular technology, applied in the field of BIPV system, can solve problems such as large gaps easily, and achieve the effect of increasing the practical range and facilitating disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

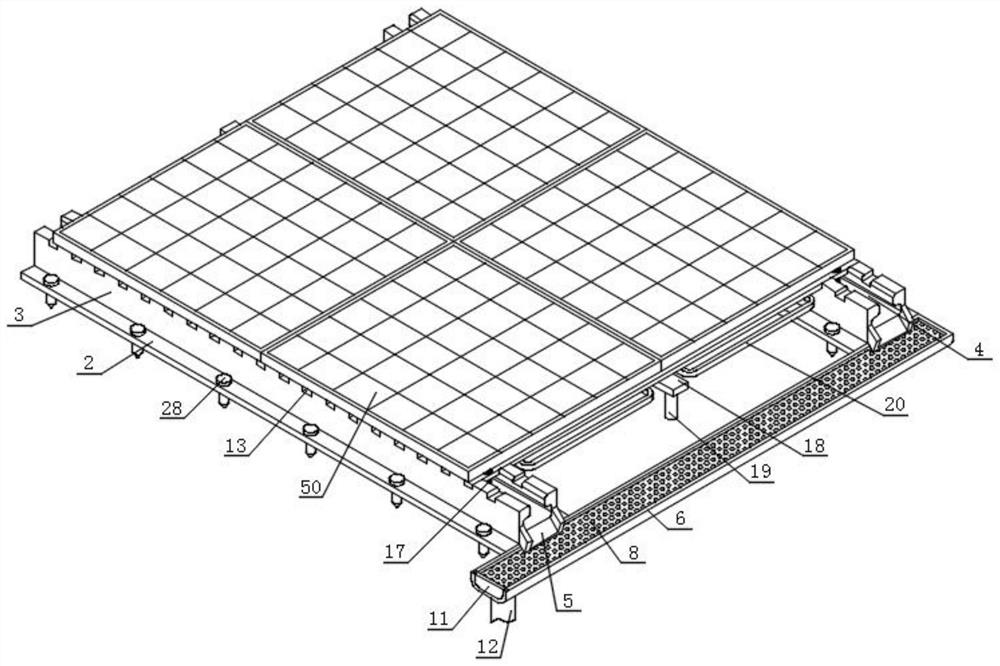

[0043] Such as figure 1 and figure 2 As shown, a modular assembled roof BIPV system and its installation method include a roof mechanism 1, a base plate 2, a support frame 3 and a fitting groove 4, and two sets of base plates 2 arranged side by side are installed on the top of the roof mechanism 1. Support frames 3 are installed on the top of the group bottom plate 2;

[0044] Fitting grooves 4 are provided on the tops of the two sets of support frames 3;

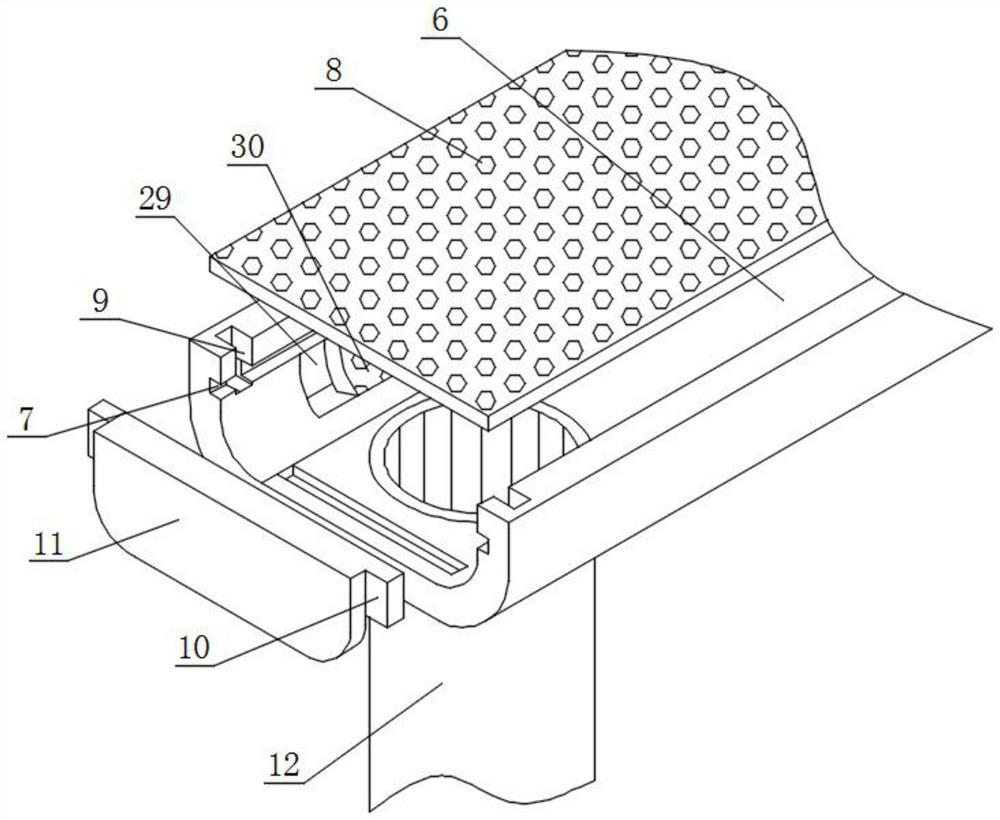

[0045] U-shaped inclined plates 5 are installed on one side of the outer walls of the two sets of support frames 3, and the U-shaped inclined plates 5 are located below the fitting groove 4, and U-shaped drainage racks 6 are installed on one side of the outer walls of the two sets of bottom plates 2. The inner walls of both sides of the drain frame 6 are provided with engaging grooves 7, and filter plates 8 are installed between the two sets of engaging grooves 7, and two sets of grooves 9 arranged in mirror images are i...

Embodiment 2

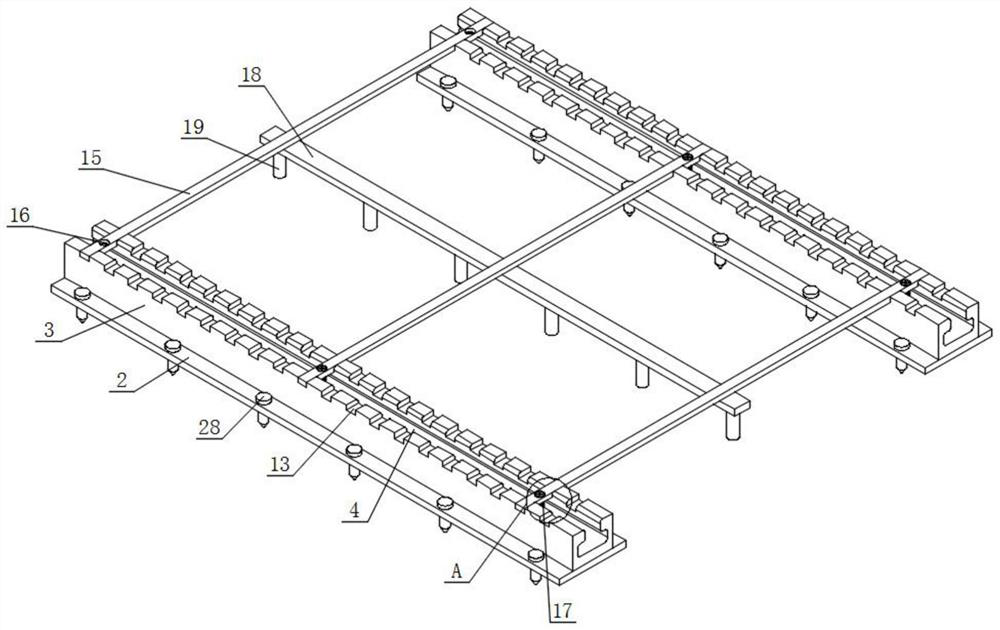

[0049] Such as image 3 , Figure 4 , Figure 6 and Figure 7 As shown, the top of the support frame 3 is provided with multiple groups of assembly grooves 13 arranged side by side, and the bottom wall of the fitting groove 4 is evenly provided with multiple groups of thread grooves 14 arranged side by side, and the number of thread grooves 14 is the same as that of the assembly grooves 13, wherein The inwalls of the three groups of assembling grooves 13 are equipped with support plates 15, the top of the support plates 15 are provided with two groups of circular grooves 16 arranged front and back, the inwalls of the two groups of circular grooves 16 are all equipped with fastening nails 17, and the fastening nails 17 The bottom extends into the interior of the threaded groove 14 .

[0050] Specifically, when assembling the device, the staff needs to engage multiple sets of support plates 15 in the assembly grooves 13 provided on the top of the support frame 3 according to ...

Embodiment 3

[0054] Such as figure 1 and Figure 5 As shown, the bottoms of the three groups of support plates 15 are equipped with two groups of double frame bodies 20 arranged front and back, and the two groups of double frame bodies 20 are respectively positioned at the front and rear of the horizontal plate 18, and the tops of the three groups of support plates 15 are equipped with four A group of evenly arranged BIPV photovoltaic mechanisms 21 .

[0055] The bottom of the BIPV photovoltaic mechanism 21 is equipped with two sets of connecting frame plates 22 arranged in mirror images, and the outer walls of the opposite sides of the two sets of connecting frame plates 22 are provided with through grooves, and the inner walls of the two sets of connecting frame plates 22 are equipped with movable cover frames 23 , and the outer walls of one side of the two groups of movable cover frames 23 run through the insides of the two groups of through grooves respectively, and the inner walls of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com