Rapid extraction method of idesia oil

An extraction method, the technology of jatropha oil, is applied in the direction of fat oil/fat production and fat production, which can solve the problems of affecting economic value, large solvent residue, and low oil yield, and achieve large-scale ultrasonic extraction and shorten extraction Time, the effect of increasing the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

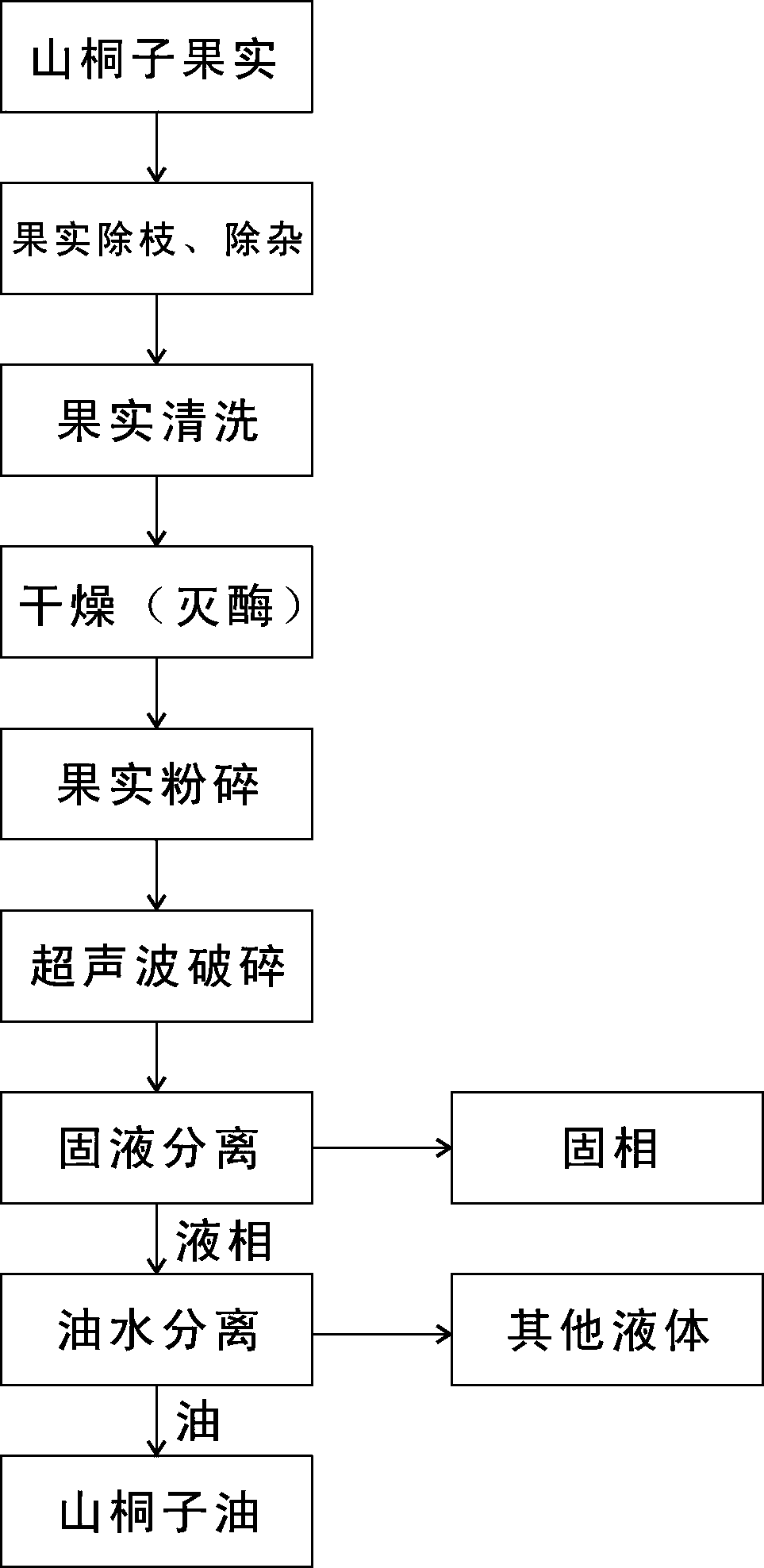

Method used

Image

Examples

specific Embodiment 1

[0019] Accurately weigh 100KG of fresh jatropha fruits that have been picked from Tongjiang County, Bazhong City, Sichuan Province, and crushed after drying and inactivating enzymes. Use the STZ-1 ultrasonic extraction tank for jatropha to crush for 20 minutes. The extractant is petroleum ether, the ultrasonic frequency is 28.1kHz, and the ultrasonic intensity is 20W / cm 2 , the ratio of material to liquid is 1:12 (g / mL), the temperature of the whole process of ultrasonic crushing is controlled at 80 degrees Celsius, and 12.4 kg of jatropha crude oil is obtained after solid-liquid separation and oil-water separation in a centrifuge.

specific Embodiment 2

[0021] Accurately weigh 100KG of fresh jatropha fruits that have been picked from Tongjiang County, Bazhong City, Sichuan Province, and crush them after drying and inactivating enzymes. Use the STZ-1 ultrasonic extraction tank for jatropha to crush for 30 minutes. The extractant uses petroleum ether, the ultrasonic frequency is 31.1kHz, and the ultrasonic intensity is 20W / cm 2 , the ratio of material to liquid is 1:15 (g / mL), the temperature of the whole process of ultrasonic crushing is controlled at 70 degrees Celsius, and 14.8 kg of jatropha crude oil is obtained after solid-liquid separation and oil-water separation in a centrifuge.

specific Embodiment 3

[0023] Accurately weigh 100KG of fresh jatropha fruits that have been picked from Tongjiang County, Bazhong City, Sichuan Province, and crush them after drying and inactivating enzymes. Use STZ-1 jatropha ultrasonic extraction tank for crushing for 35 minutes. The extractant uses petroleum ether, the ultrasonic frequency is 22.7kHz, and the ultrasonic intensity is 20W / cm 2 , the ratio of material to liquid is 1:10 (g / mL), the temperature of the whole process of ultrasonic crushing is controlled at 50 degrees Celsius, and 14.3 kg of jatropha crude oil is obtained after solid-liquid separation and oil-water separation in a centrifuge.

[0024] The invention can quickly extract the oil from the jatropha at a low temperature below 60 degrees Celsius, save the oil production time, and at the same time increase the oil yield of the jatropha per unit time without any damage to the quality of the oil and less solvent residue. This is because, when the temperature is too high, the extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com