Iron tailing far-infrared ceramic material and preparation method thereof

A technology of far-infrared ceramics and ceramic materials, applied in the field of iron tailings far-infrared ceramic materials and their preparation, can solve the problems of low utilization rate of iron tailings materials and infrared radiation ceramics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

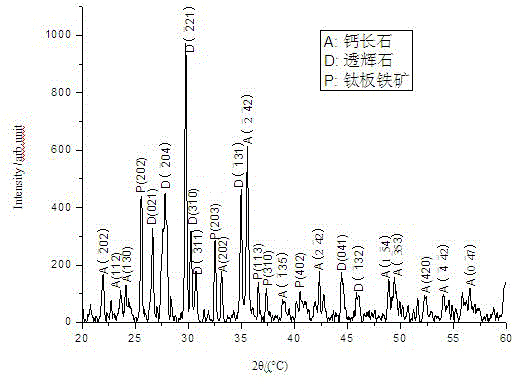

[0020] The invention mainly uses iron tailings, clay, silicon dioxide, calcium carbonate and alumina as raw materials, and after ball milling, sieving, batching, stirring, drying, mixing, dry pressing and sintering, the iron tailings can be obtained. Infrared ceramic materials. Specifically, the preparation method of the present invention adopts the weight percent composition of the iron tailings far-infrared ceramic material of the present invention and the following process steps:

[0021] A. Put the iron tailings into a ball mill and mill them for 30-120 minutes, and then pass through a 350-mesh sieve to obtain iron tailings powder;

[0022] B, get the iron tailings powder body that obtains in the step A of weight 35~75%, add the clay that is 1~9% again, the silicon dioxide of 11~25%, the calcium carbonate of 11~25%, 2~ 6% alumina, and 15-30% water by weight of the above-mentioned raw materials, mixed and kept stirring for 30-90 minutes;

[0023] C. Dry the mixture in ste...

Embodiment 1

[0036] Design a kind of preparation method that iron tailings prepares far-infrared ceramics, this preparation method adopts following process:

[0037] A. Put the iron tailings into a ball mill and mill them for 30 minutes, and pass through a 350-mesh sieve after ball milling to obtain iron tailings powder;

[0038] B. Take the iron tailings powder obtained in step A of 35% by weight, and then add 9% clay, 25% silicon dioxide, 25% calcium carbonate, 6% aluminum oxide, and the above-mentioned raw materials 15% water by weight, mix and keep stirring for 30min;

[0039] C. Dry the mixture in step B at 100°C for 1 hour;

[0040] D, after mixing the dried mixture in step C for 60 minutes by ball milling, pass through a 120-mesh sieve;

[0041] E. Press the mixture in step D under the conditions of molding pressure of 30 MPa and holding pressure for 1.5 minutes to obtain a ceramic green body, put the green body into a sintering furnace for sintering, and finally obtain iron taili...

Embodiment 2

[0045] Design a kind of preparation method that iron tailings prepares far-infrared ceramics, this preparation method adopts following process:

[0046] A. First put the iron tailings into a ball mill for ball milling for 60 minutes, and pass through a 350-mesh sieve after ball milling to obtain iron tailings powder;

[0047] B. Take the iron tailings powder obtained in step A of 45% by weight, and then add 7% clay, 22% silicon dioxide, 22% calcium carbonate, 4% aluminum oxide, and the above-mentioned raw materials 20% water by weight, mix and keep stirring for 50min;

[0048] C. Dry the mixture in step B at 105°C for 1 hour;

[0049] D, after mixing the dried mixture in step C for 70 minutes by ball milling, pass through a 120-mesh sieve;

[0050] E. Press the mixed material in step D under the conditions of molding pressure of 30MPa and holding pressure for 1min to obtain a ceramic green body, put the green body into a sintering furnace for sintering, and finally obtain ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com