Reverse osmosis seawater desalination system using self-pressurization energy recycling high-pressure pump

An energy recovery, high-pressure pump technology, applied in osmosis/dialysis water/sewage treatment, reverse osmosis, seawater treatment, etc., can solve the problem of high energy consumption of small reverse osmosis seawater desalination systems, reduce volume and weight, and simplify the design process , the effect of reducing energy consumption and equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

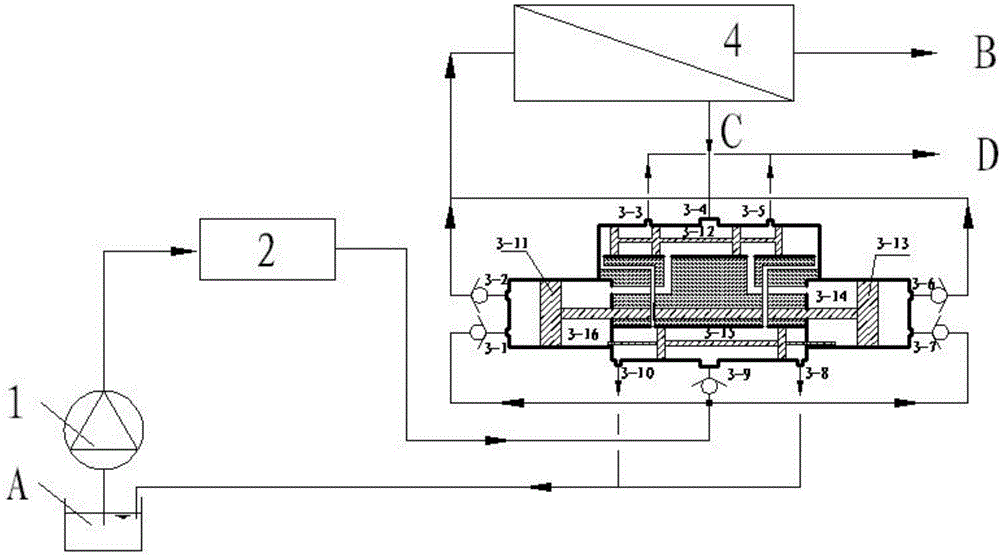

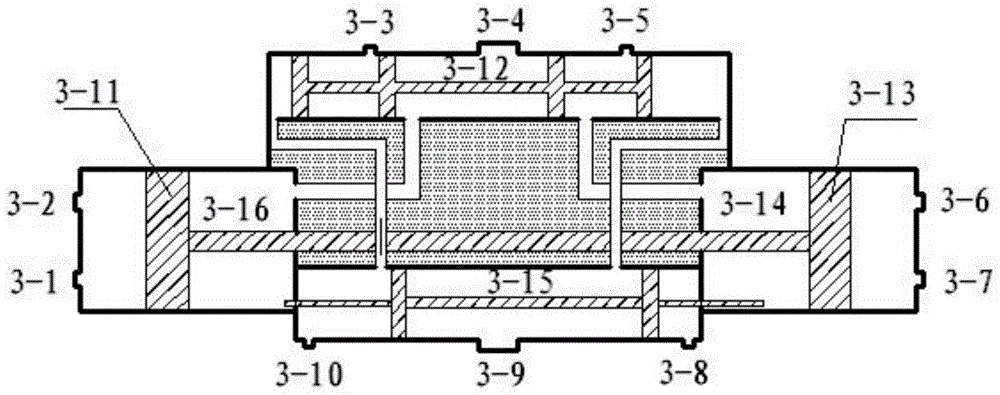

[0026] In conjunction with the accompanying drawings, the typical work flow of the small reverse osmosis seawater desalination system using the self-pressurized energy recovery high-pressure pump provided by the present invention is described:

[0027] Raw water first enters the hydraulic cylinder 3-16 (or hydraulic cylinder 3-14) from the liquid flow hole 3-1 (or liquid flow hole 3-7), and pushes the hydraulic piston 3-11 (or hydraulic piston 3-13) to the right (or to the left) movement, thereby pushing the pilot control valve 3-15 to move to the right (or left) limit position; after that, the liquid flow hole 3-1 (or liquid flow hole 3-7) is closed, and the low-pressure water inlet hole 3- 9 is opened, the raw water enters the interior of the pilot control valve 3-15 from the low-pressure water inlet hole 3-9, and then enters the inner space of the reversing control valve 3-12 through the inner flow channel of the center block, and pushes the reversing control valve 3-12 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com