Forming method and forming tool for hinge plate parts

A technology of hinges and parts, which is applied in the field of mechanical parts production, can solve problems such as failure to form, failure of bending and rounding, and poor quality of bending parts, so as to achieve the effects of saving production costs, avoiding mechanical damage, and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

[0024] Embodiment of the present invention: a forming method of a hinge part, the method is to add a U-shaped bending process to the traditional hinge connecting hole forming process, so as to realize the fast and accurate forming of the hinge connecting hole .

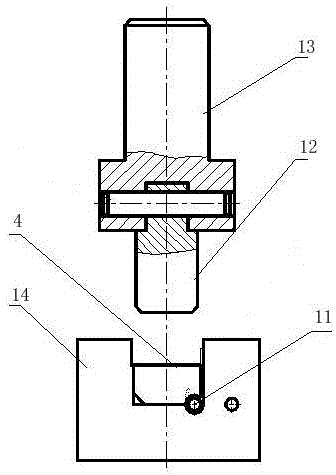

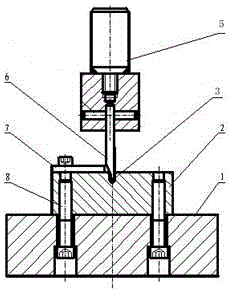

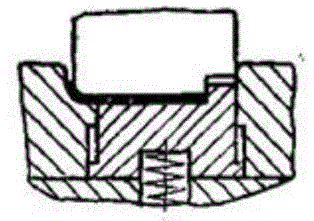

[0025] The specific method is to pre-bend the head of the hinge connecting hole blank according to the existing technology and tooling. The size of the pre-bending arc is 1 / 4 to 1 / 6 of the actual hinge connecting hole. Press the hinge blank, the length from the pressing position to the end of the hinge blank is 3 / 4 of the length of the entire hinge blank, so that the hinge blank has a U-shaped structure, and finally passes through the core The rod is placed in the U-shaped structure and the hinge blank head is rolled into a circle by the hinge form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com