Okra yogurt beverage and preparation method thereof

A technology for okra juice and beverages, which is applied in dairy products, milk preparations, applications, etc., can solve the problems of inconvenience in large-scale promotion, unsuitable drinking, and ineffective effects, so as to enhance endurance and immunity, and prevent cardiovascular disease. Disease, efficacy synergistic remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this example, the product includes raw materials according to the following mass ratio: 4.5% milk powder, 15% okra juice, 0.2% L-arabinose, 8% sucrose, 0.05% casein phosphopeptide, 0.02% gamma-aminobutyric acid %, sodium carboxymethylcellulose 0.4%, monoglyceride 0.05%, lactic acid 2.4%, citric acid 0.3%, sodium citrate 0.05%, food flavor 0.2%, iron element 0.005%, potassium sorbate 0.02%, and the rest is water.

[0031] The thickener is sodium carboxymethyl cellulose; the emulsifier is monoglyceride; the sour agent is lactic acid and citric acid; the buffer salt is sodium citrate; and the mineral is iron.

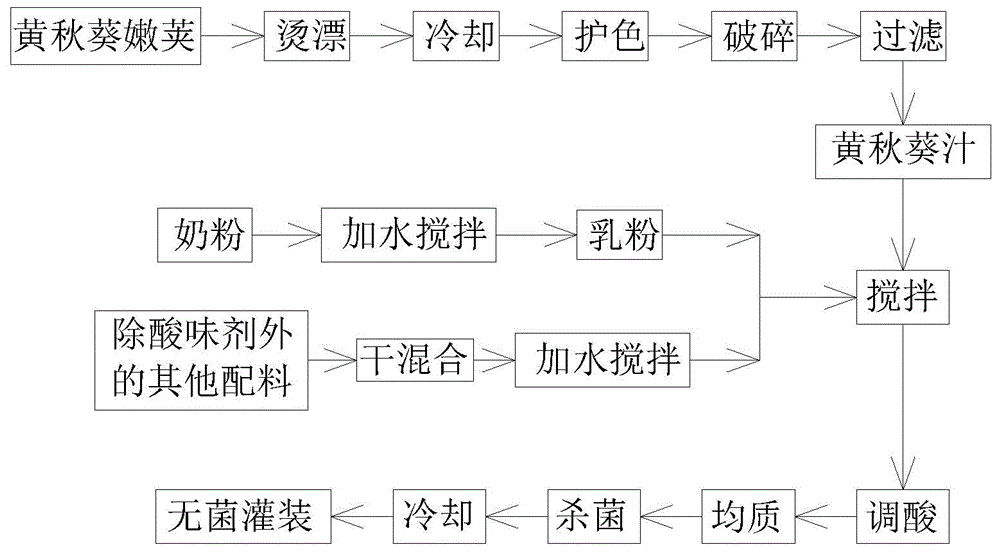

[0032] like figure 1 Shown, product preparation process comprises the following steps:

[0033] Step 1. Wash the young okra pods and put them in boiling water to blanch for 3 minutes, take them out and put them in a cooling room at 10°C for cooling for 2 minutes, then add the untreated okra pods to the cooled okra pods The weight of water such as okra tender p...

Embodiment 2

[0040] In this example, the product includes raw materials according to the following mass ratio: 4.5% milk powder, 15% okra juice, 0.1% L-arabinose, 8% sucrose, 0.05% casein phosphopeptide, sodium carboxymethyl cellulose 0.2%, xanthan gum 0.1%, pectin 0.1%, monoglyceride 0.05%, lactic acid 0.5%, citric acid 0.5%, sodium citrate 0.05%, vitamin D 0.001%, calcium element 0.05%, potassium sorbate 0.02 %, the rest is water.

[0041] The thickener is sodium carboxymethylcellulose, xanthan gum and pectin; the emulsifier is monoglyceride; the sour agent is lactic acid and citric acid; the buffer salt is sodium citrate; The vitamin is vitamin D; the mineral is calcium element.

[0042] like figure 1 Shown, product preparation process comprises the following steps:

[0043] Step 1. Wash the young okra pods and put them in boiling water to blanch for 5 minutes, take them out and put them in a cooling room at 6°C for cooling for 3 minutes, then add the untreated okra pods to the coole...

Embodiment 3

[0050] In this example, the product includes raw materials according to the following mass ratio: 3% milk powder, 20% okra juice, 0.2% L-arabinose, 8% sucrose, 0.05% casein phosphopeptide, sodium carboxymethyl cellulose 0.2%, PGA0.1%, pectin 0.2%, monoglyceride 0.05%, lactic acid 0.025%, citric acid 0.25%, sodium citrate 0.05%, zinc element 0.05%, potassium sorbate 0.02%, and the rest is water.

[0051] The thickener is sodium carboxymethylcellulose, PGA and pectin; the emulsifier is monoglyceride; the sour agent is lactic acid and citric acid; the buffer salt is sodium citrate; for the zinc element.

[0052] like figure 1 Shown, product preparation process comprises the following steps:

[0053] Step 1. Wash the young okra pods and put them in boiling water to blanch for 4 minutes, take them out and put them in a cooling room at 8°C for 2.5 minutes, then add the untreated okra pods to the cooled okra pods The weight of water such as tender pods of okra, the quality of pulp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com