In-house production technology for hydroponic swamp cabbages

A water spinach and hydroponics technology, applied in the field of vegetables, can solve the problems of high power consumption, low efficiency of supplementary light, matching emission spectra and absorption spectra, etc., and achieve the effects of fast and robust plant growth, reliable technical solutions, energy saving and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] ①Preparation of seedlings: 1-2 days after the spinach seeds are germinated, they are directly broadcast into the sponge square matrix, and cultivated in nutrient solution hydroponically to 2-3 true leaves.

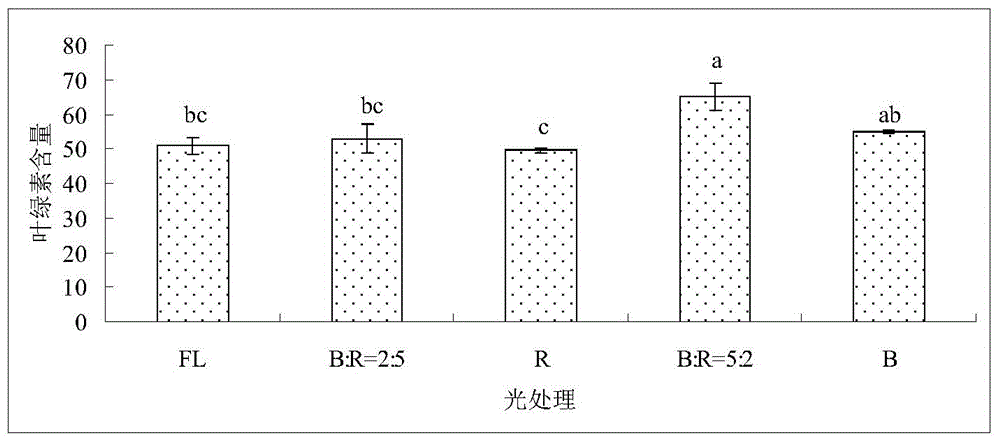

[0026] ② Light treatment: Wrap the water spinach seedlings with a sponge and plant them in the planting holes on the floating foam board in the hydroponic tank, and then place them under the blue-red combination 5:2 rare earth plant light source for hydroponic cultivation.

[0027] ③Condition control: the light intensity in the light treatment stage is 100μmol·m -2 ·s -1 , the photoperiod is 12 hours, the culture temperature is 26-30° C., the humidity is 70±10%, and the culture time is 35 days.

[0028] ④Control method: The light source is provided by rare earth plant growth lamps, the light intensity is controlled by adjusting the number of lamps and the distance from the lamps to the plant canopy, and a timing device is used to control the photoperiod.

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com