Device for introducing force into a component of fibre composite material

A technology of fiber composite materials and components, which is applied in the connection between superstructure subassemblies, connecting components, superstructure, etc., and can solve problems such as connection failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

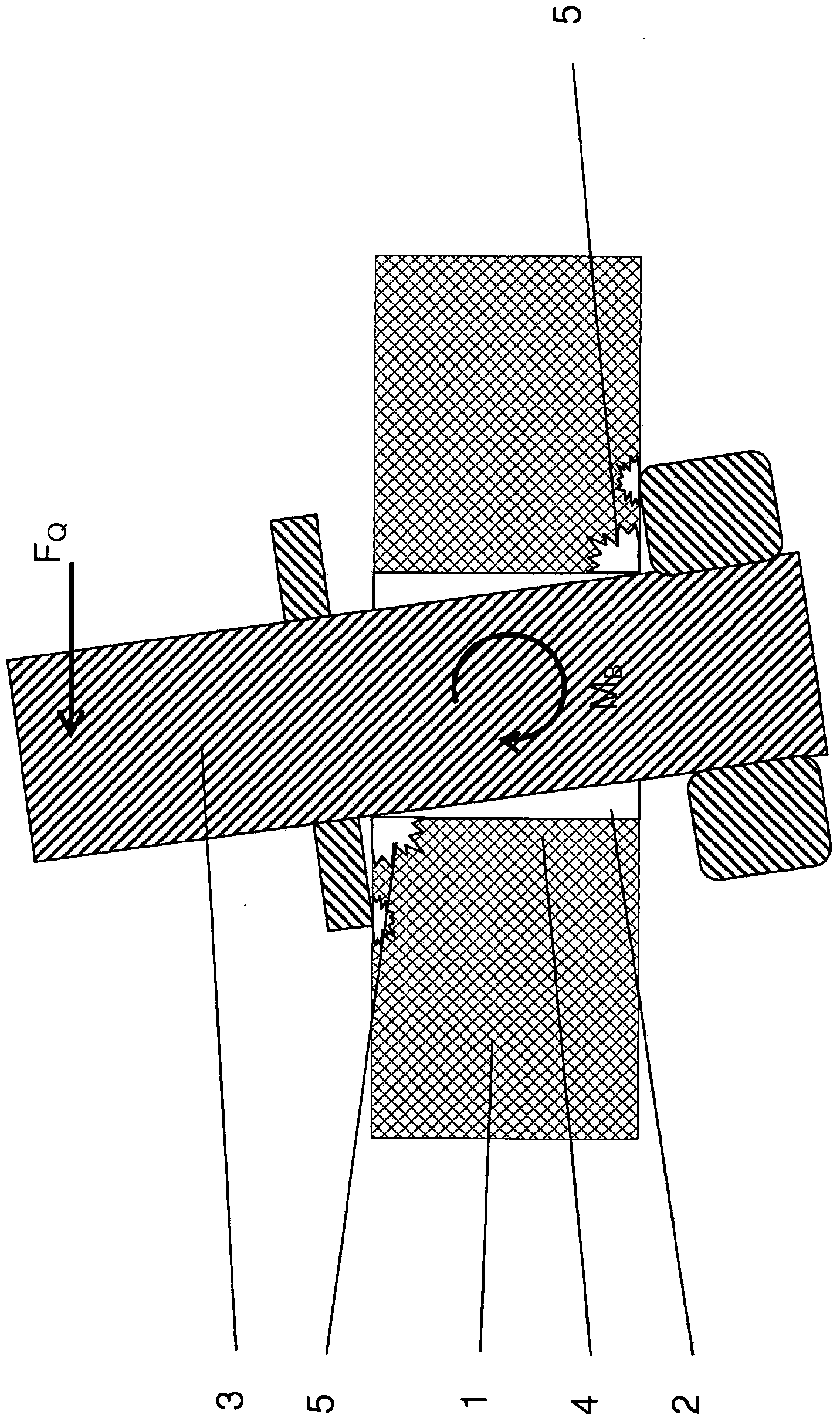

[0038] FIG. 1 shows a device according to the prior art for introducing forces into a plate-like component 1 made of fiber composite material. A bolt 3 passing through a bore 2 of the component 1 is connected to the component 1 by means of a screw connection. A structural element, not shown, acts on a free end of the screw 3 . The plane of the structural member is parallel to the plane of the plate resulting in a transverse force F Q A transverse force, in particular still dynamic, is introduced pointwise into component 1 on one side of component 1 and via the lever arm of screw 3 . Even though the bolt 3 is clamped axially positively and nonpositively to the component by means of a threaded connection, there is no protection against overturning or the bending moment M B and thus the inclination of the bolt 3 in the hole 2 of the component 1 . During the continuous load caused by the force-introducing structural parts, the vulnerable hole inner side 4 of the hole 2 is subje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com