Magnetic field sensor

A magnetic field sensor and magnetic core technology, applied in the field of magnetic field sensors, can solve the problems of reducing the operating frequency range of distributed capacitance sensors, not considering the influence of sensor measurement, not considering electric field shielding measures, etc., and achieving light weight, increased distance, and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

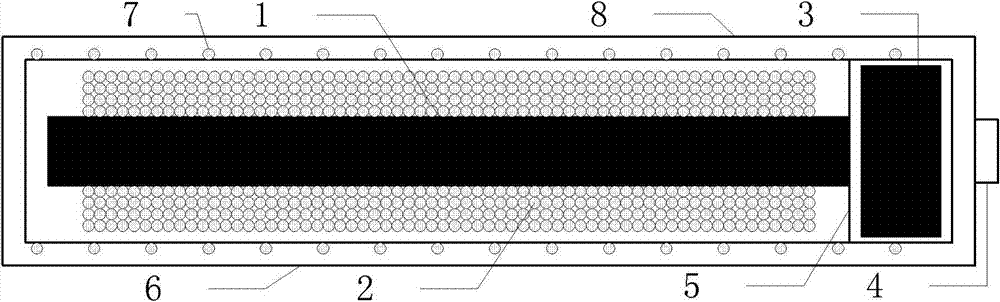

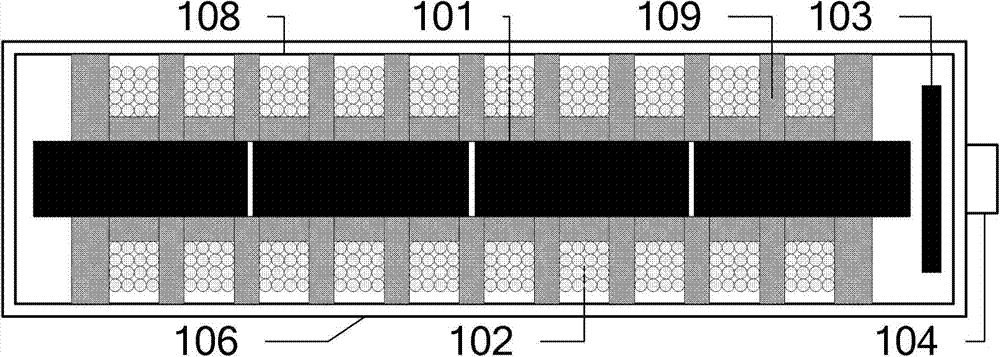

[0025] figure 2 A schematic structural diagram of a magnetic field sensor proposed by the present invention is shown. Such as figure 2 shown, which includes:

[0026] The segmented magnetic core 101 is placed in the hollow part of the hollow skeleton 109. It is a cylindrical structure and is formed by bonding multiple segments of equal-length magnetic materials. Considering the high magnetic permeability and electrical conductivity of the magnetic core material, it is preferably ferrite Material, the conductivity of ferrite is low, only 0.2x10-5S / m, it is an insulator, and it is better than magnetic materials such as permalloy with high conductivity.

[0027] Using multi-sections of ferrite of equal length to bond in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com