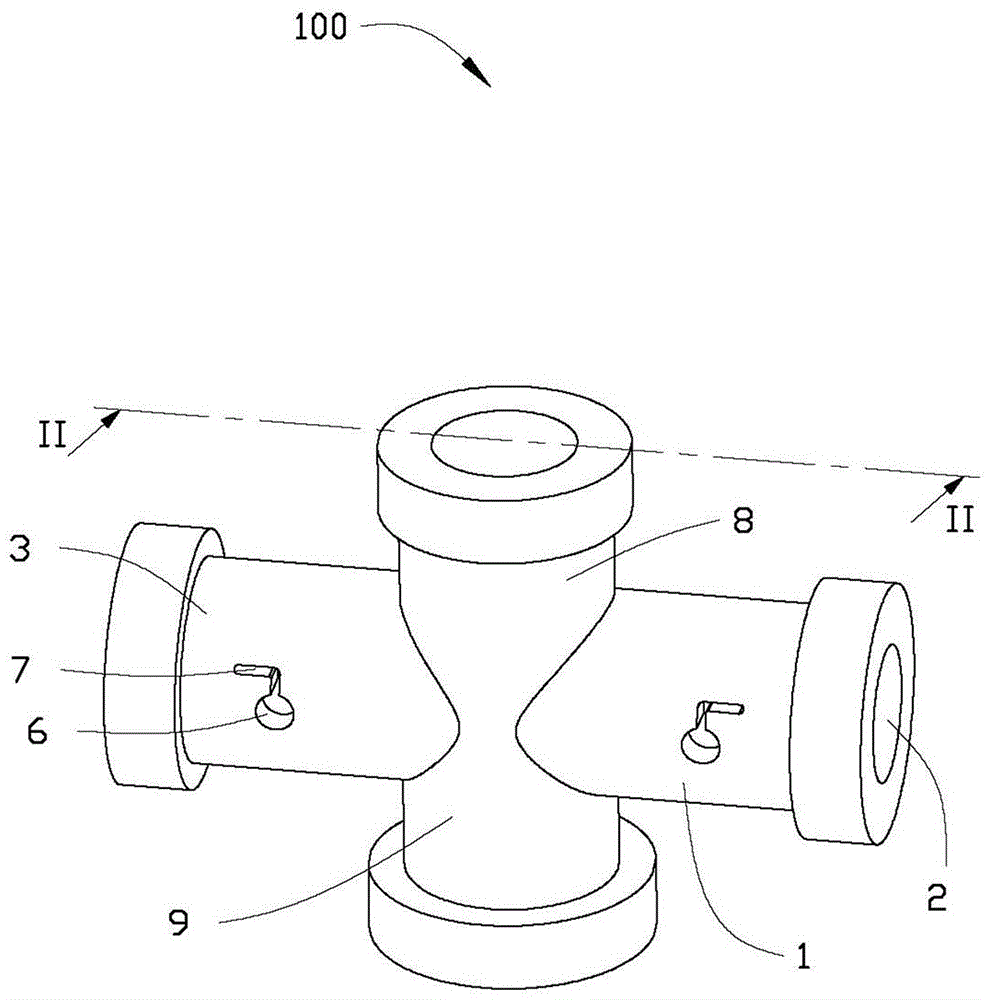

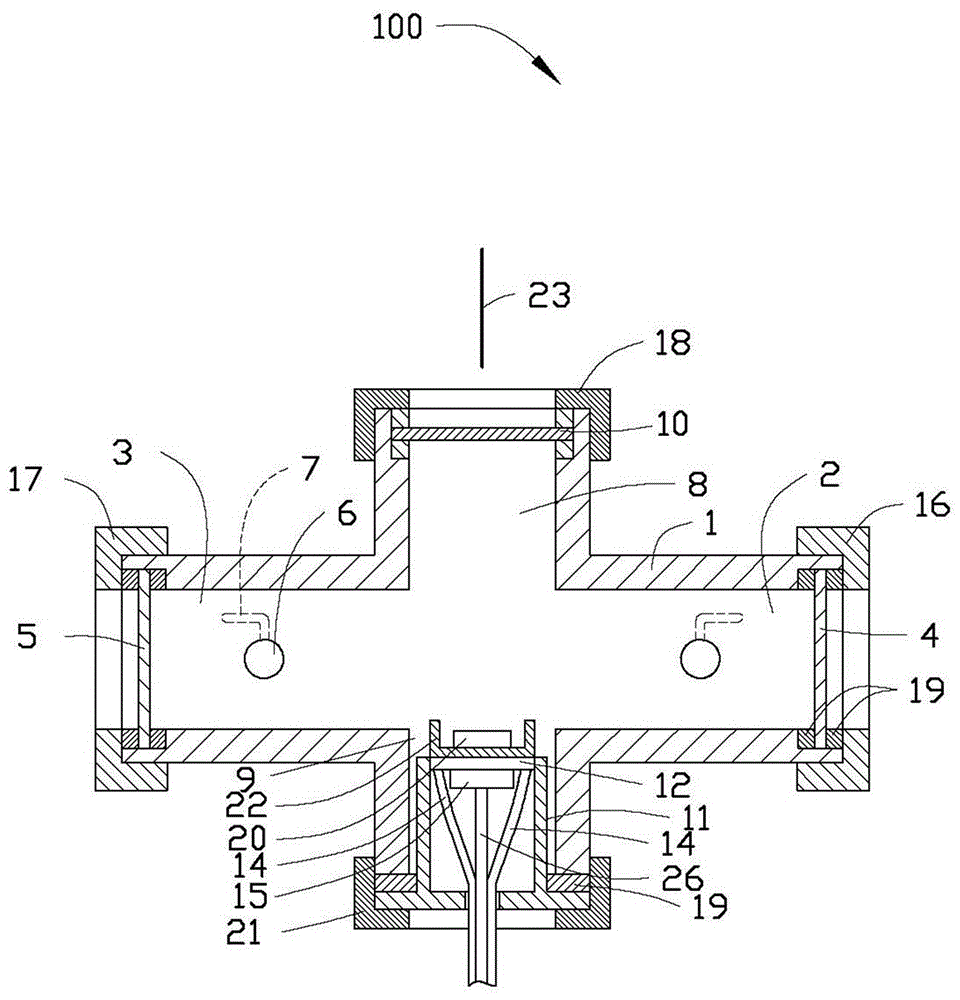

In Situ Infrared Spectroscopy Cell

A technology of infrared spectroscopy and infrared light, which is applied in the field of in-situ infrared spectroscopy testing devices, can solve the problems of low heating efficiency and can not meet the requirements, and achieves the effects of high heating efficiency, wide application and improved experimental efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

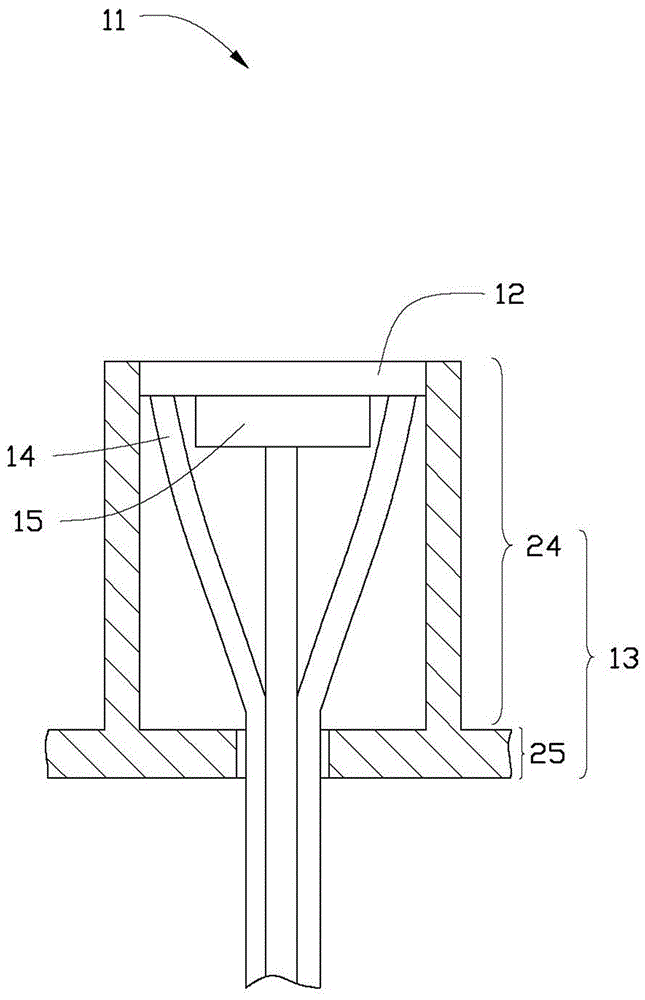

[0063] In this embodiment, the in-situ infrared spectroscopy cell 100 is used to detect volatilization of additives in nitrile rubber under heating conditions. First, put nitrile rubber in the sample boat, then set it in the in-situ infrared spectrum cell 100, heat the nitrile rubber to 150°C, during the heating process, collect the in-situ infrared spectrum cell at regular intervals Gas signal within 100. refer to Figure 5 and Figure 6 , the analysis of the gas signal collected in the in-situ infrared spectrum cell 100 shows that the peak area of the additive increases with the test time, indicating that the additive is continuously volatilized during the heating process of the nitrile rubber.

Embodiment 2

[0065] In this embodiment, the in-situ infrared spectrometer cell 100 is used to detect the carbon dioxide produced by the polyethylene film under light conditions. First, put polyethylene film in the sample boat, then set it in the in-situ infrared spectroscopy cell 100, irradiate the polyethylene film with a 150W xenon lamp through the light port 8, and turn off the xenon lamp after irradiating for 180 minutes, during which time intervals Gas signals in the in-situ infrared spectroscopy cell 100 are collected. refer to Figure 7 and Figure 8 According to the analysis of the gas signal collected in the in-situ infrared spectroscopy cell 100, the polyethylene film produces carbon dioxide under the irradiation of the xenon lamp, and the carbon dioxide is continuously produced with the light, and the generation of the carbon dioxide stops once the light stops.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com